Coal shearer and its cutting section

A technology for the cutting part of a coal shearer and a coal shearer, which is applied in the direction of earth drilling, cutting machinery, driving devices, etc., can solve the problems of frequent torque shaft breakage, many overload situations, and inconvenient disassembly of the torque shaft, and achieve saving Effects of material and time costs, reduced operating costs, and reduced downtime maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

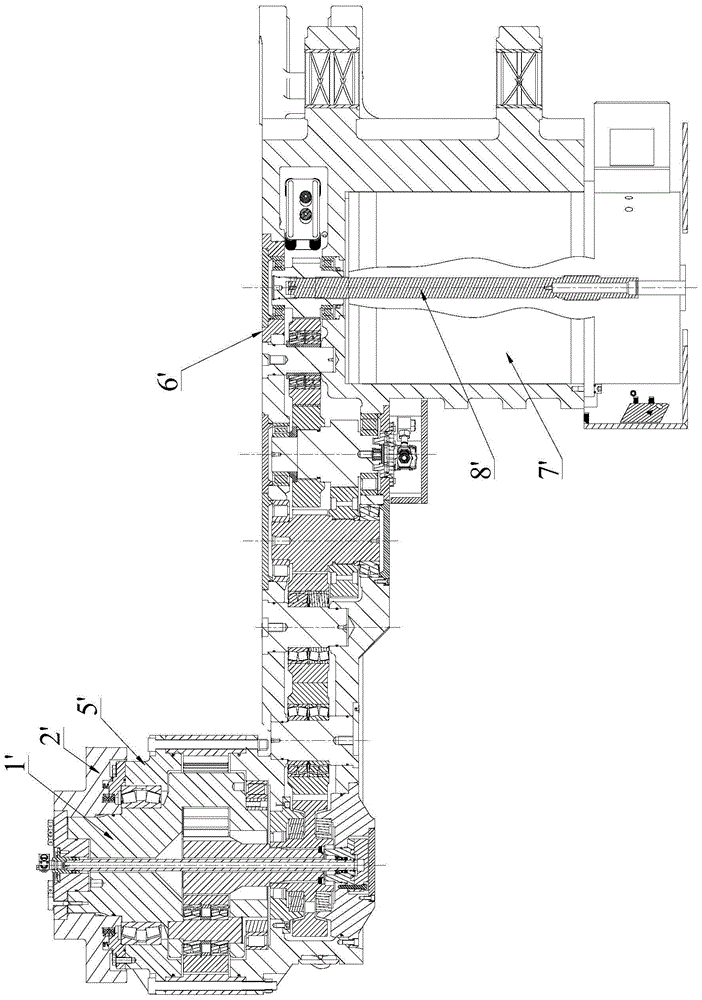

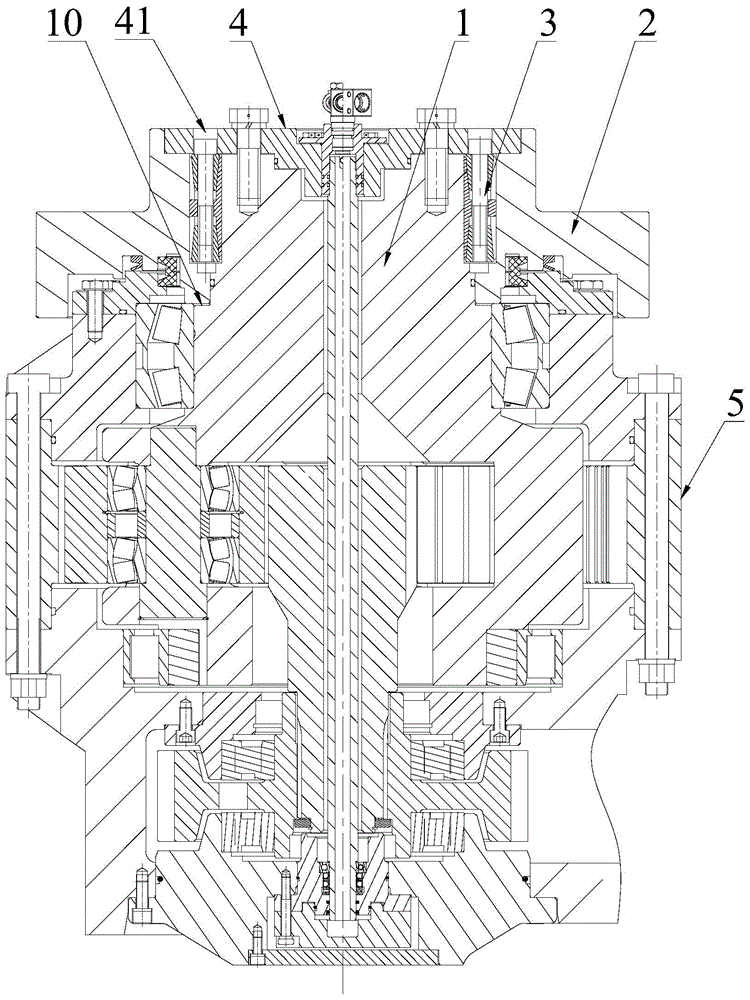

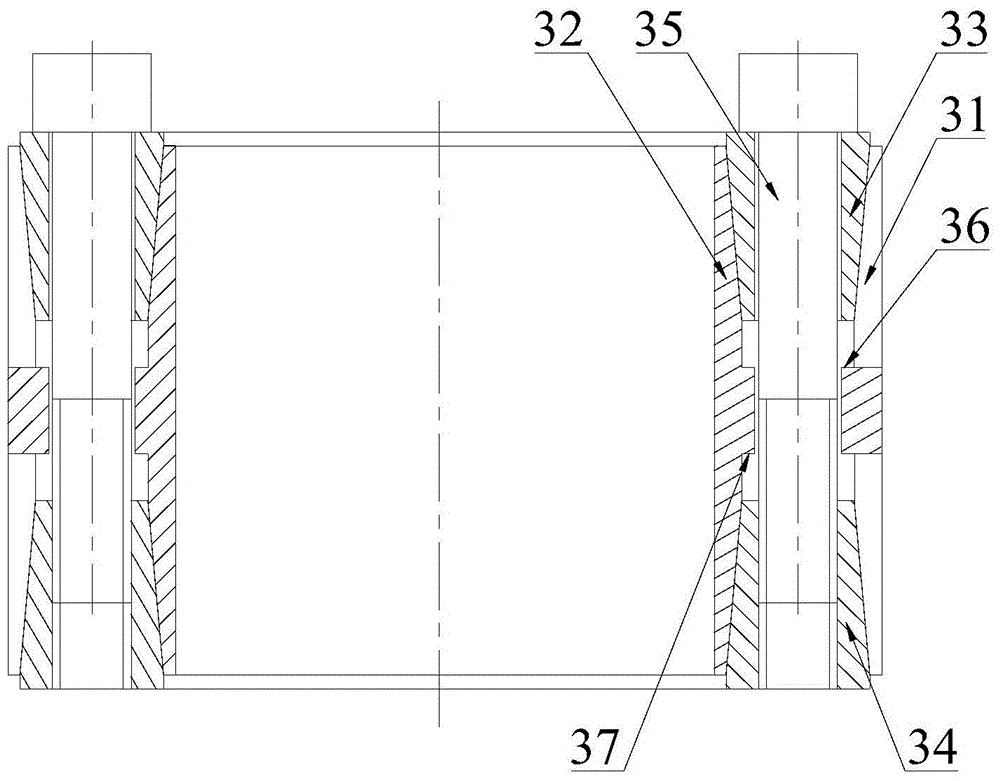

[0024] The shearer cutting part provided by the embodiment of the present invention includes a reduction transmission mechanism and a connecting square head. The reduction transmission mechanism has a power output shaft 1, see figure 2 , shows a part of the reduction transmission mechanism (planetary reducer part) and the cross-sectional structure of the connecting square head 2 in the cutting part of the shearer provided by the embodiment of the present invention. According to the prior art, the cutting part of the shearer may also include a cutting motor and a torque shaft, and the torque shaft may have an overload protection function and a clutch function. The speed reduction transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com