Fault diagnosis and maintenance method, system and device, and storage medium

A fault diagnosis and maintenance technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of targeted maintenance of the robot's operating status, and achieve the effect of reducing downtime maintenance costs, reducing downtime times, and improving purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

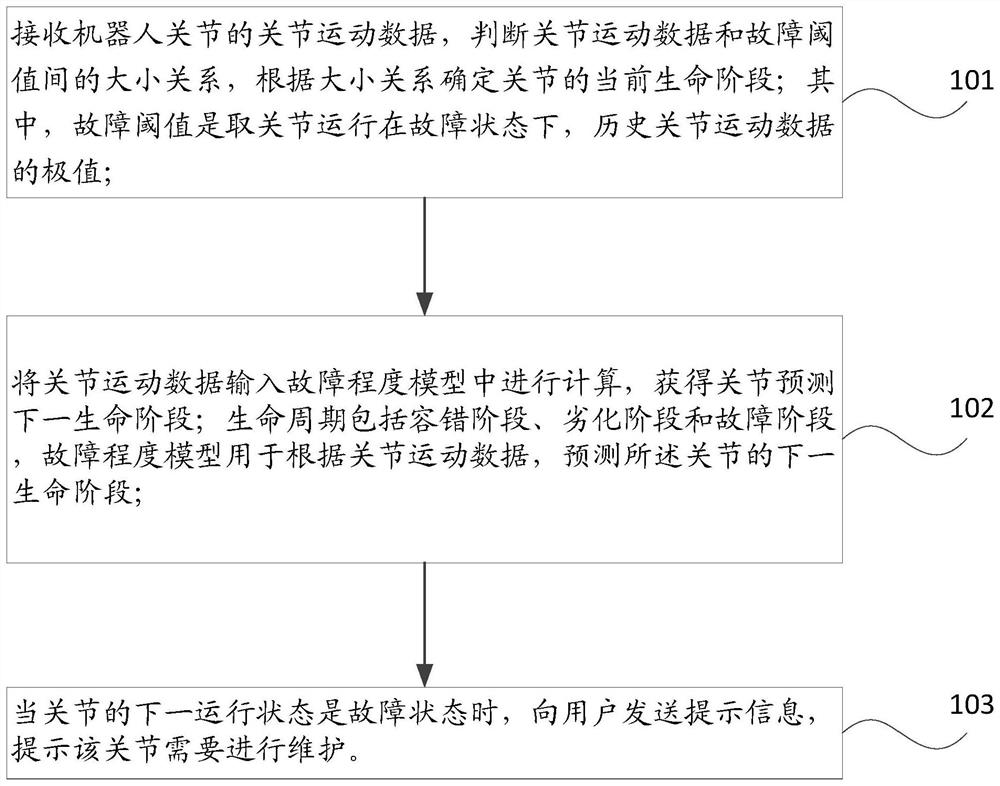

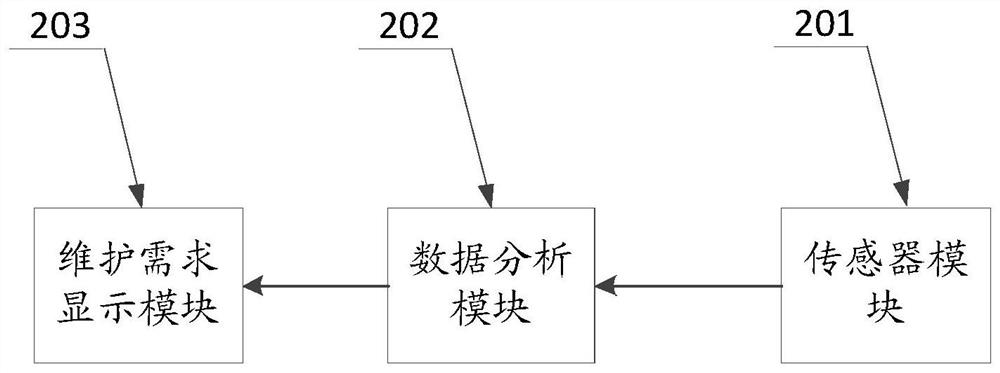

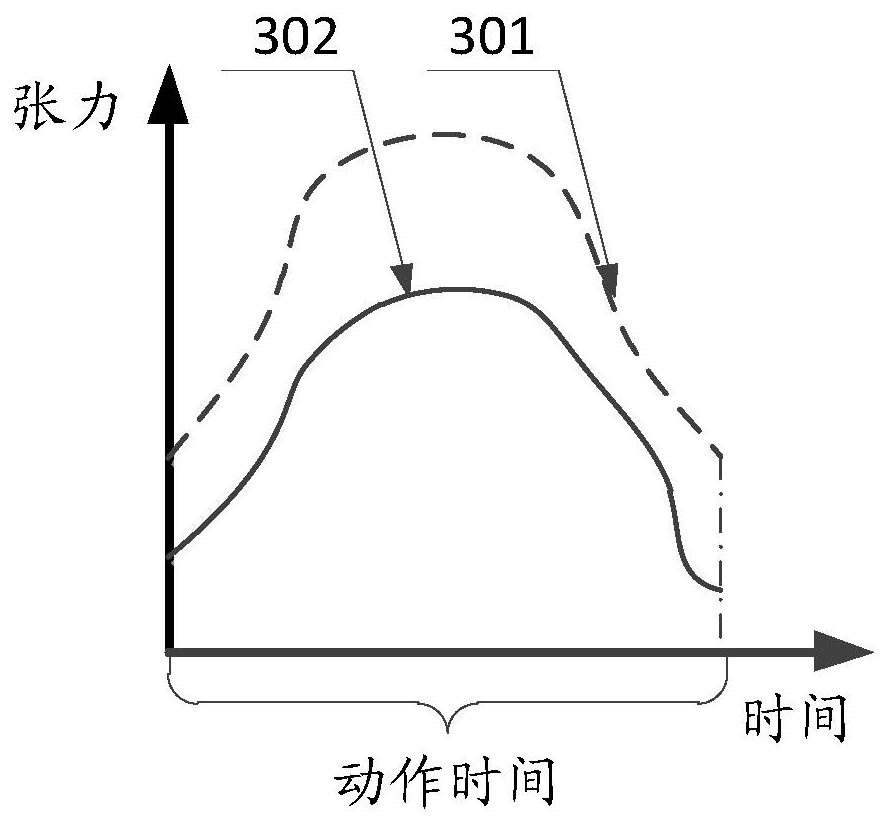

[0049] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0050] In the prior art, the existing robot maintenance system is a maintenance system based on regular maintenance and irregular maintenance schemes, and usually does not have functions such as fault detection, fault diagnosis, and fault prediction at the same time. Actual users of robots are not clear about the quantifiable effect of maintenance on the degree of improvement in equipment. Maintenance behavior as a kind of important information is lost, resulting in the loss of effective information such as failure prediction and diagnosis information. The robot maintenance system does not include predictive maintenance. Fault diagnosis relies on the after-sales service of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com