Bagasse prevention device for press machine in sugarcane sugar factory

A press machine and sugarcane sugar technology, applied in the direction of extracting juice from sugarcane, etc., can solve the problems of difficulty in feeding sugarcane material into the roll, affecting the passage of cane material, and fluctuations in steam used for cooking, so as to reduce labor intensity of workers and reduce downtime for maintenance Cost, the effect of stabilizing the extraction rate of the press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

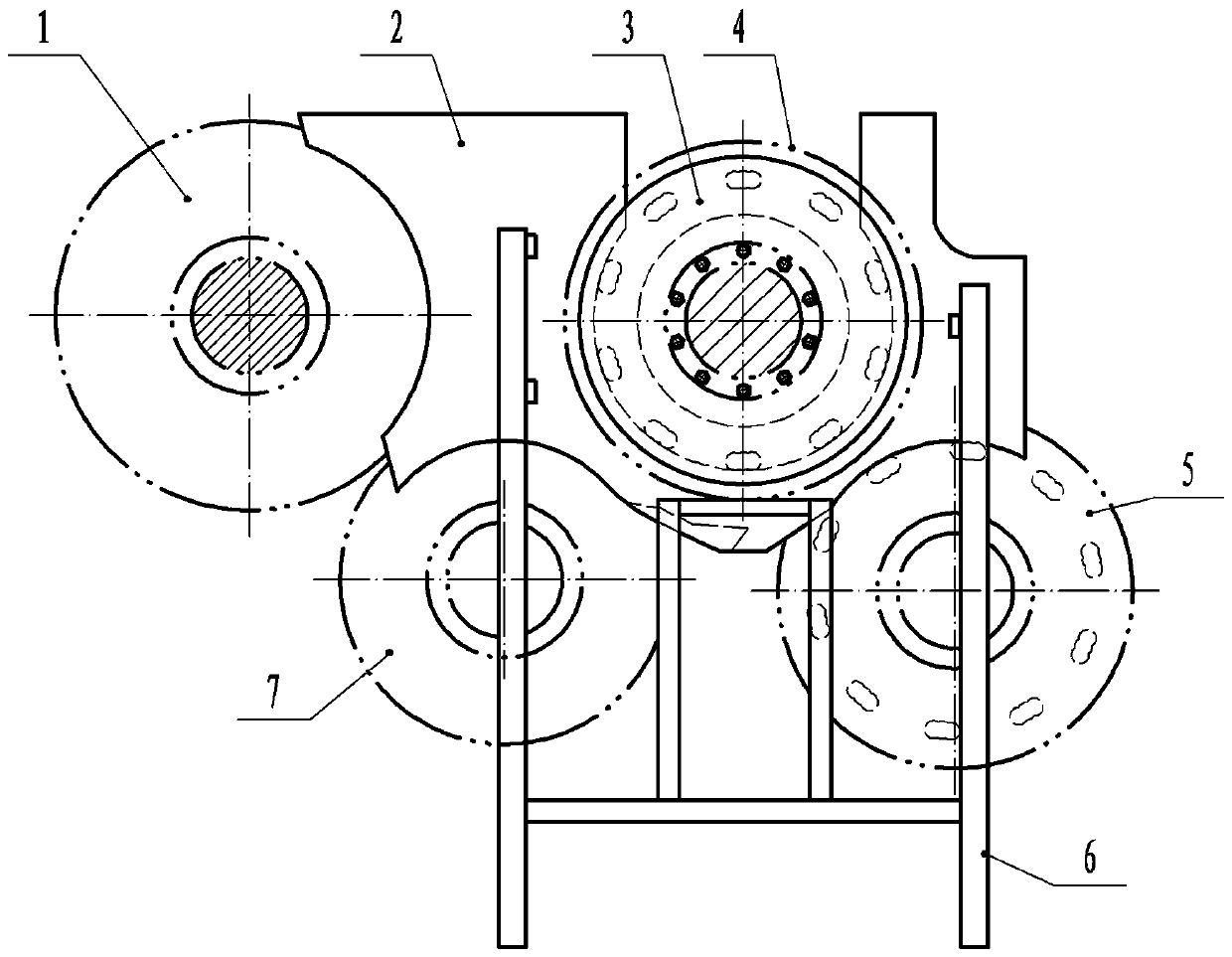

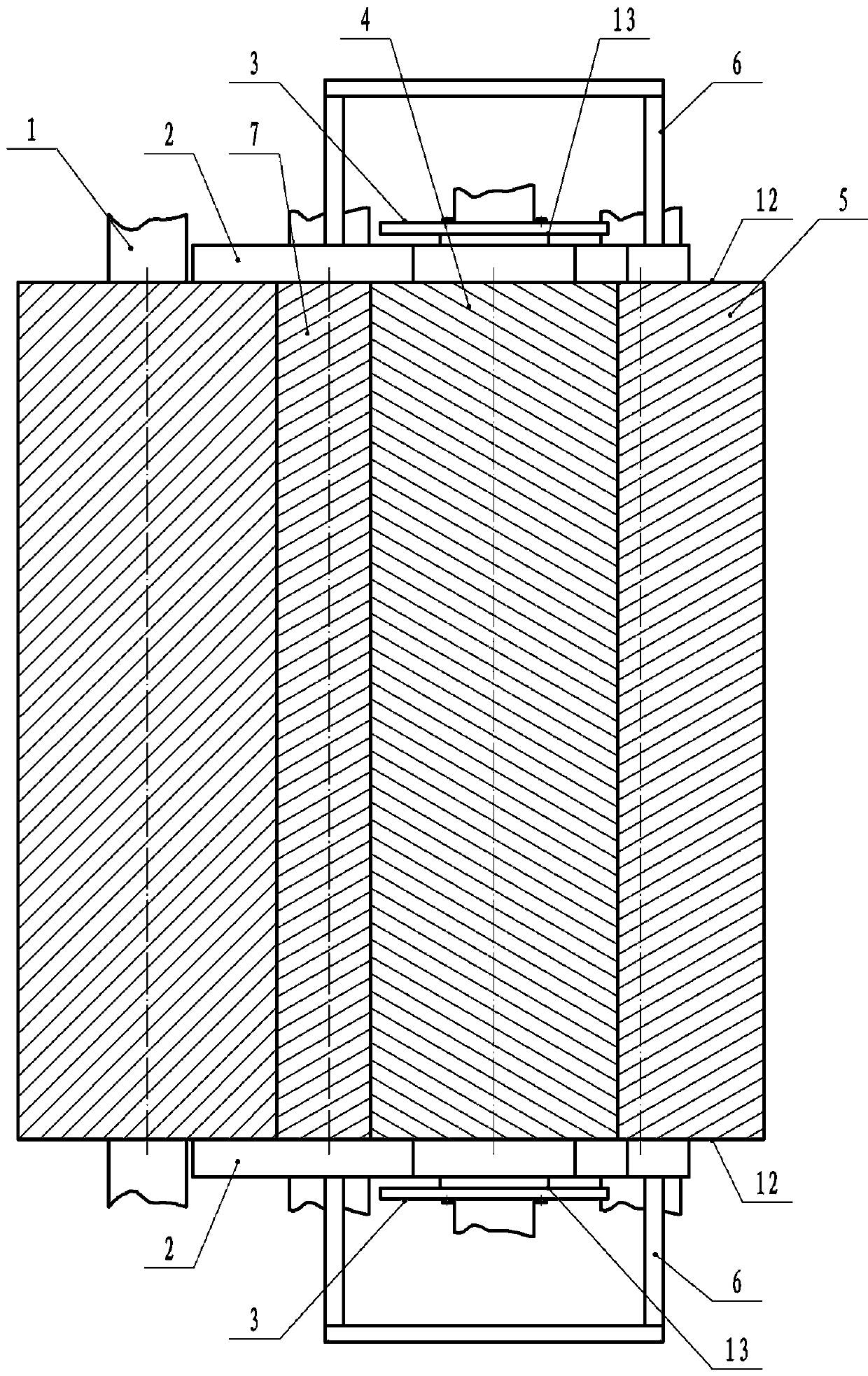

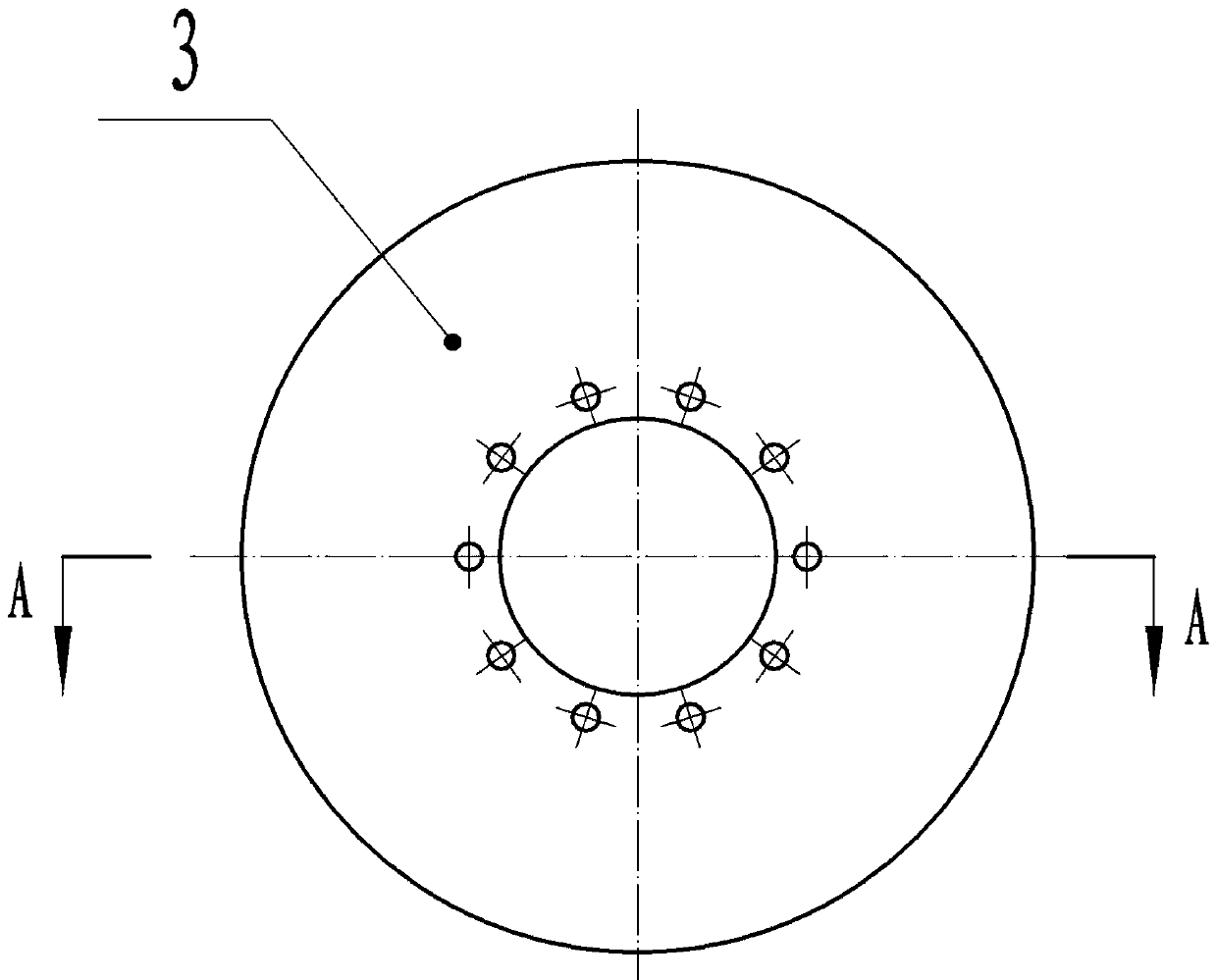

[0029] As shown in the figure: the anti-bagasse blocking device of the sugarcane sugar factory press machine of the present invention includes a baffle plate 2, a large meson 3 and a bracket 6, and the baffle plate 2 is provided with a feeding roller installation arc 8 and a front roller installation arc 9 , rear roller installation arc 10 and top roller installation arc 11; , the front roller 7, the rear roller 5 and the top roller 4 are installed in corresponding positions; the baffle plate 2 is installed on the top roller end face 12 of the top roller 4 of the press through the bracket 6 respectively, and the large meson 3 is installed on the two ends of the top roller 4 respectively. 13 on the shoulder.

[0030] The opening position of the top roller installation arc 11 coincides with or is close to the upper edge of the lotus root hole of the top roller 4 .

[0031] The opening position of described rear roller installation arc 10 coincides with the upper edge of the lot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com