Two-way sealing butterfly valve

A two-way sealing, butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of reducing the sealing performance of the butterfly valve, and the sealing is not reliable enough during the period of no medium circulation, so as to reduce the medium residue, use reliable, and improve the sealing. efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing of description, the present invention will be further described.

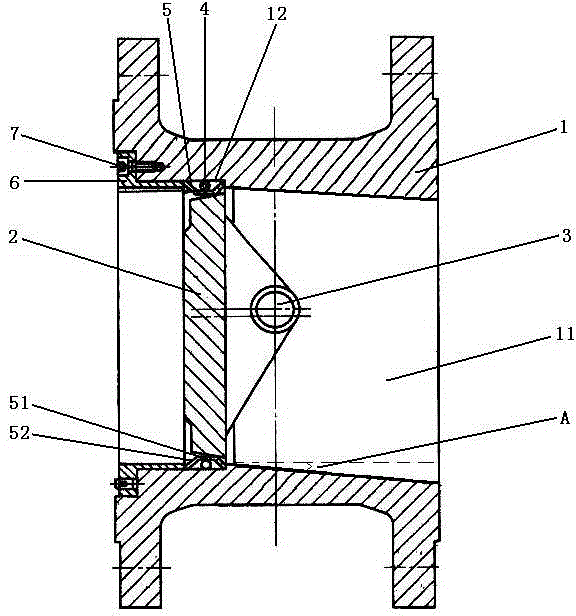

[0018] Such as figure 1 As shown, a two-way sealing butterfly valve includes a valve body 1, a butterfly plate 2 installed in the valve body 1, and a two-way sealing assembly of the valve seat, and is connected with the butterfly plate 2 to drive the butterfly plate 2 to open or close the medium channel of the valve body The valve stem 3 of 11; the valve body medium channel 11 is arranged obliquely, and the axial direction of the valve body medium channel 11 forms a 2-5 degree inclined angle A with the horizontal direction; the inclined angle A is preferably 3 degrees .

[0019] Wherein, the valve seat two-way sealing assembly includes an O-ring 4 installed in the valve seat groove 12, a basin-shaped sealing ring 5 that is pressed into the O-ring 4 and falls into the valve seat groove 12, and a top The pressure ring 6 holding the basin-shaped sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com