Buckle type connecting piece reliability test method

A test method and connector technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve problems such as differences, non-uniformity, aging, etc., and achieve improved reliability and high market competition. Powerful, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

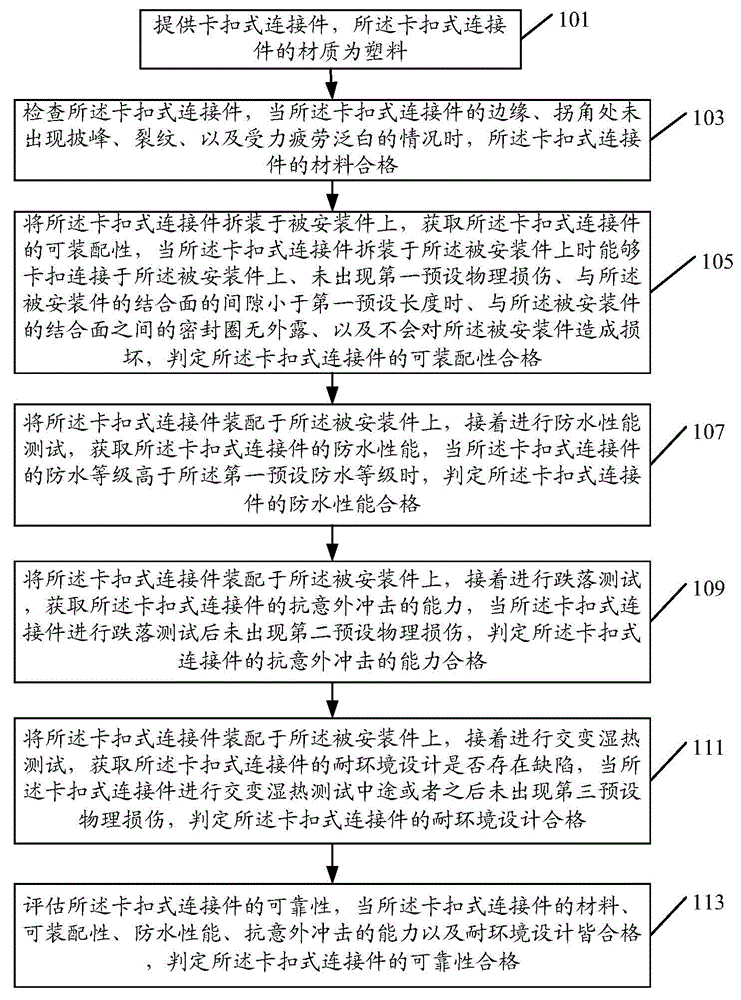

[0028] see figure 1 , a method for testing the reliability of snap-fit connectors provided in an embodiment of the present invention. The method includes the following steps:

[0029] Step 101: Provide a buckle-type connector, and the material of the buckle-type connector is plastic. The number of snap-fit connectors is determined according to actual conditions. In this embodiment, the number of snap-fit connectors is 20. Certainly, in other implementations, the number of snap-fit connectors may also be 10, 30 or more.

[0030] Step 103: Check the snap-fit connector. When there are no peaks, cracks, or whitening under stress and fatigue at the edges and corners of the snap-fit connector, the snap-fit connector The material is acceptable. This step is mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com