Light guide plate printing ink adsorptivity test method

A technology of adsorption performance and testing method, which is applied in the field of ink adsorption performance testing of light guide plates, and can solve problems such as poor light guide effect of light guide plates, uniformity of surface light sources that cannot meet the use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention aims at the problem of whether the ink peeling off of the light guide plate will cause the light guide effect of the light guide plate to deteriorate, the uniformity of the surface light source cannot meet the use requirements, and there is no effective test method for the long-term use of the light guide plate. It provides a test method for the ink adsorption performance of the light guide plate method.

[0020] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

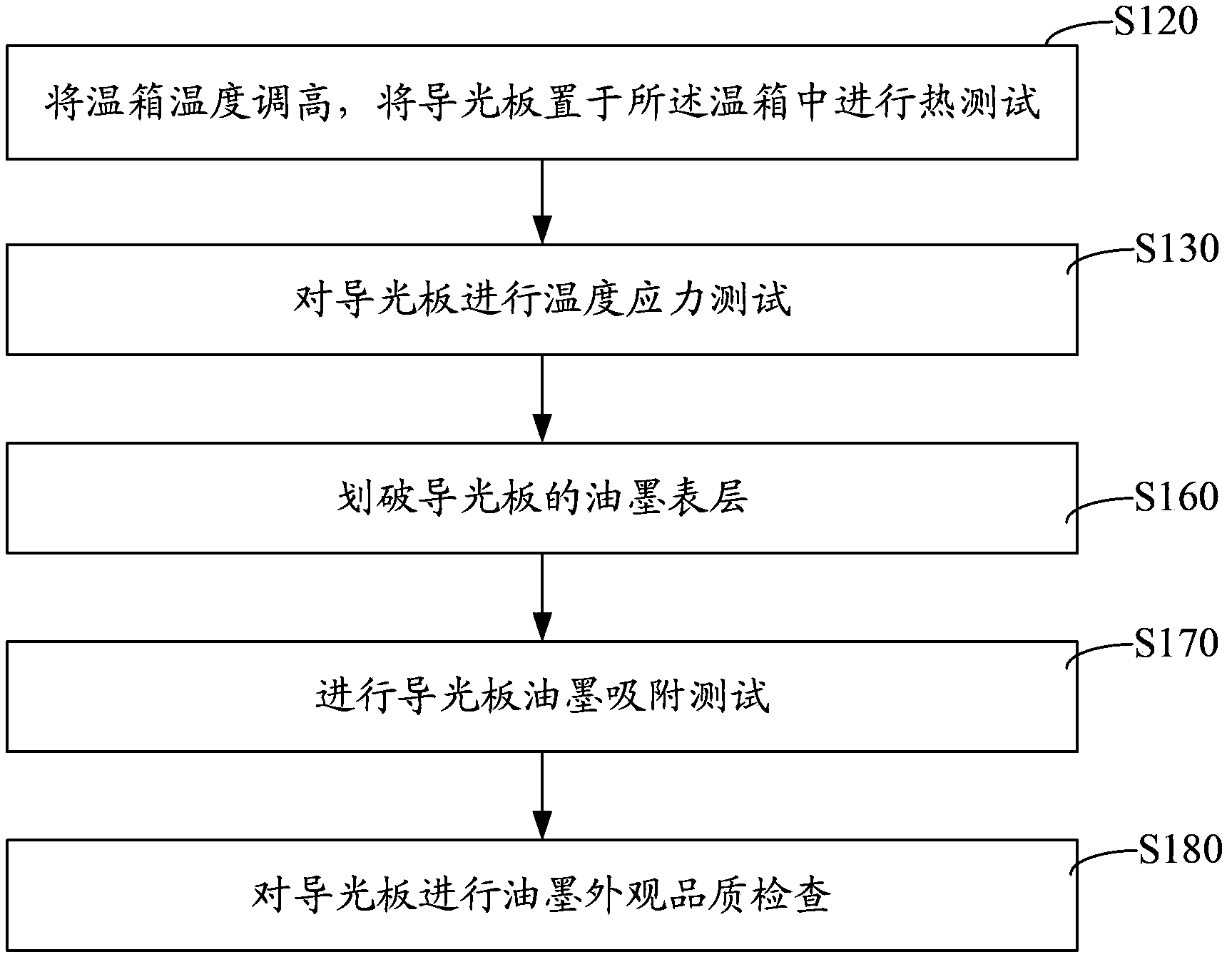

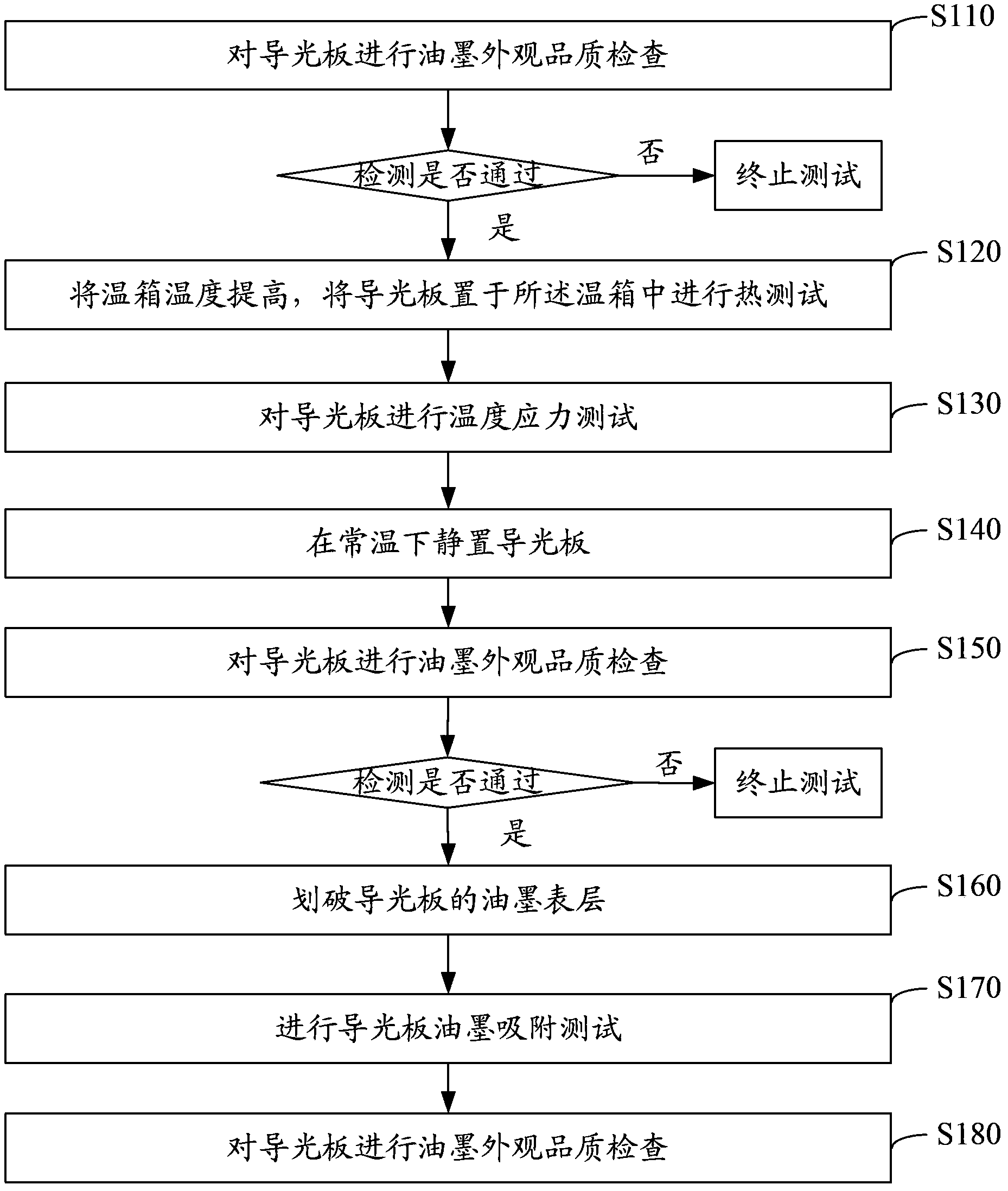

[0021] figure 1 It is a flow chart of the method for testing the ink absorption performance of the light guide plate in one embodiment, including:

[0022] Step S120: Increase the temperature of the incubator, and place the light guide plate in the incubator to conduct a thermal test.

[0023] In this embodiment, the temperature of the incubator was adjusted to 65 degrees Celsius, and the thermal test time was 100 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com