A micro power generation device

A power generation device, miniature technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of high cost of use, small power generation, resource consumption, etc., and achieve the effect of high work reliability, large power generation, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

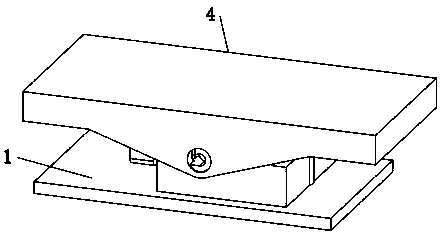

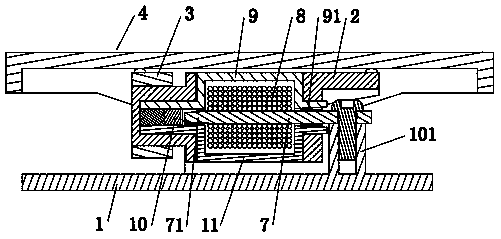

[0041] Such as Figure 1 to Figure 5 As shown, it is a micro power generation device, including a power generation structure, a base 1, a mounting sleeve 2 and a pressing seesaw structure 4; wherein

[0042] A mounting frame 101 is provided on the base 1, and shaft sleeves 102 are respectively provided on both sides of the mounting frame 101, and rotating shafts 21 are respectively provided on both sides of the mounting sleeve 2, and the two rotating shafts 21 are installed to rotate respectively. In the two shaft sleeves 102, the installation sleeve 2 is on the installation frame 101 and can swing up and down;

[0043] Described power generation structure comprises magnetic guide bar 7, electromagnetic coil 8, upper magnetic guide plate 9, permanent magnet 10 and lower magnetic guide plate 11; Described upper magnetic guide plate 9, lower magnetic guide plate 11 and permanent magnet 10 are all fixed on In the installation sleeve 2, the permanent magnet 10 is located between ...

Embodiment 2

[0052] Such as Figure 6 to Figure 10 As shown, it is a micro power generation device, including a power generation structure, a base 1, a mounting sleeve 2, a pressing seesaw structure 4 and an elastic sheet 6; wherein

[0053] An installation frame 101 is arranged on the base 1, and shaft sleeves 102 are respectively arranged on both sides of the installation frame 101, and a rotating shaft 21 is respectively arranged on both sides of the installation sleeve 2, and the two rotating shafts 21 rotate respectively. installed in the two shaft sleeves 102, so that the installation sleeve 2 can swing up and down on the installation frame 101;

[0054] Described power generation structure comprises magnetic guide bar 7, electromagnetic coil 8, upper magnetic guide plate 9, permanent magnet 10 and lower magnetic guide plate 11; Described upper magnetic guide plate 9, lower magnetic guide plate 11 and permanent magnet 10 are all fixed on In the installation sleeve 2, the permanent m...

Embodiment 3

[0062] Such as Figure 11 to Figure 14 As shown, it is a micro power generation device, including a power generation structure, a base 1, a mounting sleeve 2, a pressing structure 4 and an elastic sheet 6; wherein

[0063] The right part of the base 1 is provided with an installation frame 101, and the front and rear sides of the installation sleeve 2 are provided with an installation shaft 21. Can swing up and down within 101;

[0064] Described power generation structure comprises magnetic guide bar 7, electromagnetic coil 8, upper magnetic guide plate 9, permanent magnet 10 and lower magnetic guide plate 11; Described upper magnetic guide plate 9, lower magnetic guide plate 11 and permanent magnet 10 are all fixed on In the installation sleeve 2, the permanent magnet 10 is located between the left end of the upper magnetic guide plate 9 and the lower magnetic guide plate 11; the electromagnetic coil 8 is wound on the magnetic guide rod 7, and the electromagnetic coil 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com