Charging method and system of split type process calibrator and storage medium

A charging method and calibrator technology, applied in the field of process calibrator, can solve problems affecting product quality, unusable, complicated charging operation, etc., and achieve the effect of increasing working time, increasing working time, and long working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

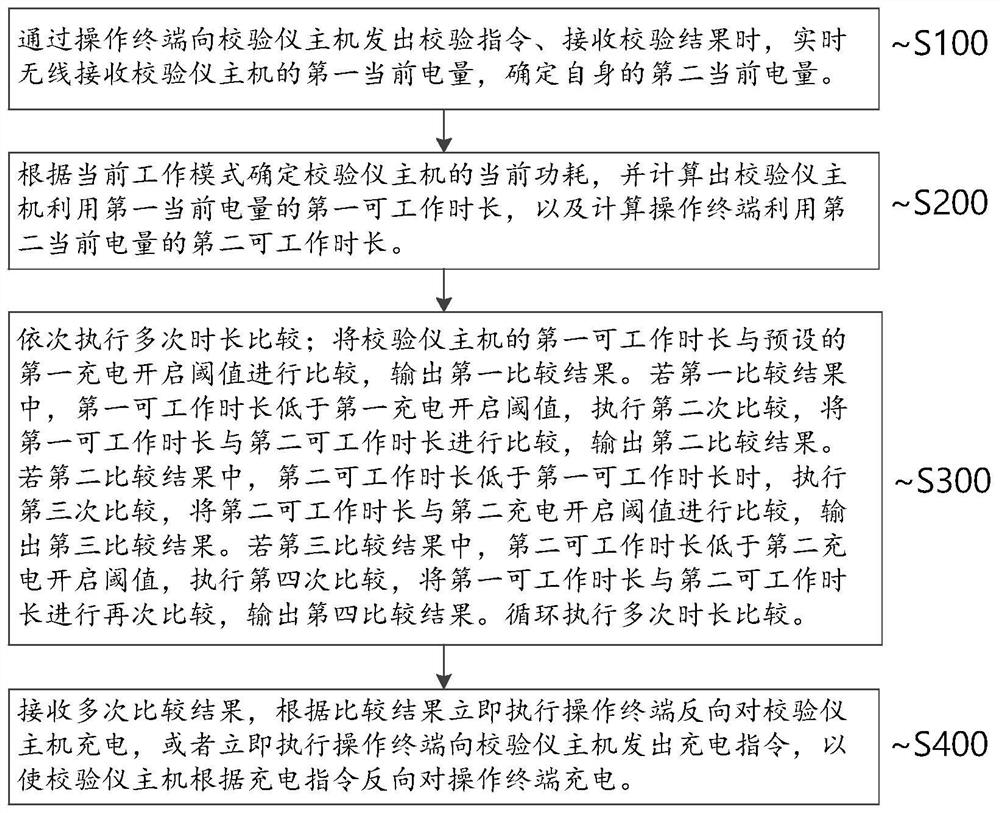

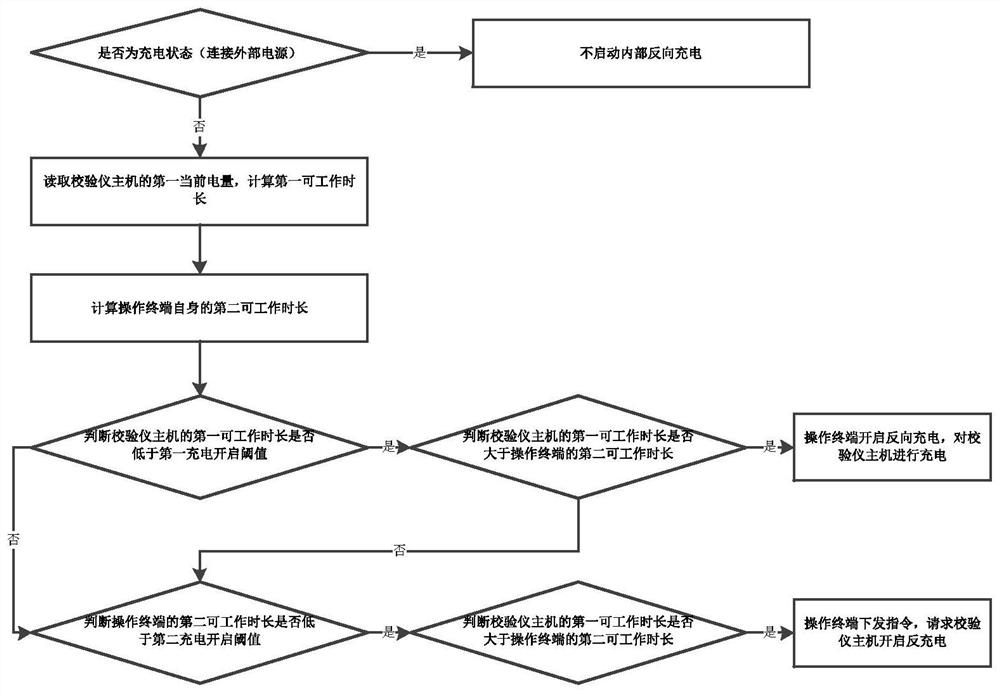

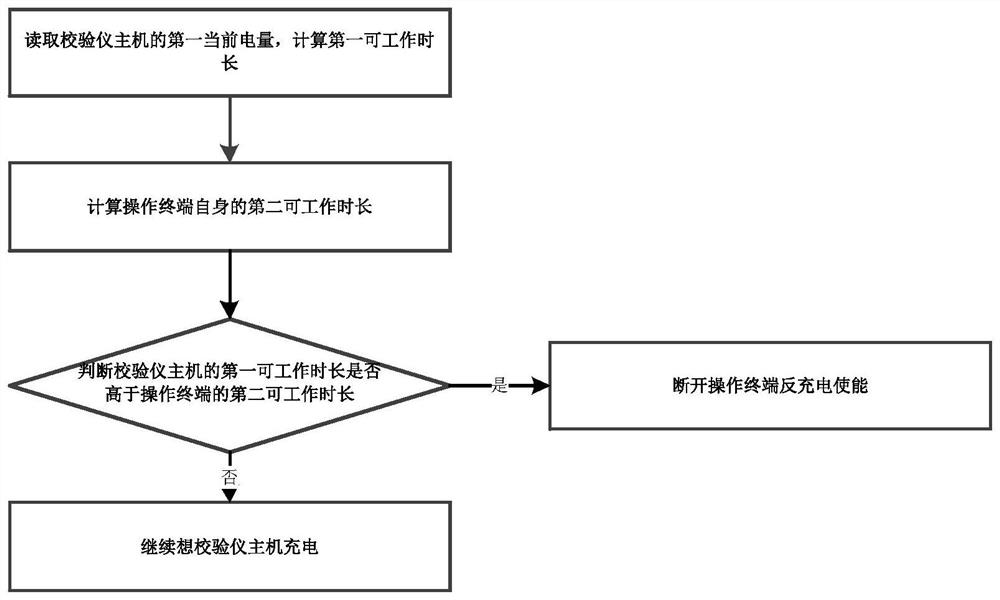

[0062] Reference attached Figure 1-4 As shown, the embodiment of the present application provides a charging method for a split-type process calibrator, including an operation terminal and a calibrator host, and the operation terminal is connected to the calibrator host both wirelessly and wired.

[0063] Before describing the technical solution for charging in this embodiment, relevant terms will be explained first. Among them, the process calibrator is represented as a hand-held battery-powered portable signal calibrator, which has two functions of measurement and output, and can measure and output voltage, current, resistance, thermocouple, thermal resistance and other signals. . The split-type process calibrator is expressed as an innovative product as an integrated process calibrator. With the help of wireless communication technology, the integrated process calibrator is separated, and the separated display and operation parts are formed into independent modules. As t...

Embodiment 2

[0091] Reference attached Figure 5 , 8 The illustrated embodiment of the present application provides a charging system for a split-type process calibrator, and the system adopts the charging method for the split-type process calibrator in Embodiment 1. The system is divided into the following components from the charging function.

[0092] The power acquisition module 100 is configured to wirelessly receive the first current power of the calibrator host in real time and determine its own second current power when the operation terminal sends a calibration command to the calibrator host and receives the calibration result.

[0093] The duration calculation module 200 is configured to determine the current power consumption of the main body of the calibrator according to the current working mode, and calculate the first working time for the main body of the calibrator to use the first current power, and calculate the time for the operation terminal to use the second current p...

Embodiment 3

[0111] An embodiment of the present application provides a computer-readable storage medium. The computer-readable storage medium stores computer codes. When the computer codes are executed, any one of the methods in Embodiment 1 is executed.

[0112] Those skilled in the art should understand that the embodiments of the present invention may be provided as methods, systems, or computer program products. Accordingly, the present invention can take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present invention may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com