A device for testing the function and reliability of the automotive peps system

A system function and reliable technology, applied in the direction of vehicle testing, machine/structural component testing, electrical measurement, etc., can solve problems such as poor consistency, inability to simulate real vehicle status, single working conditions, etc., to shorten the development cycle, Reduce market failure rate and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

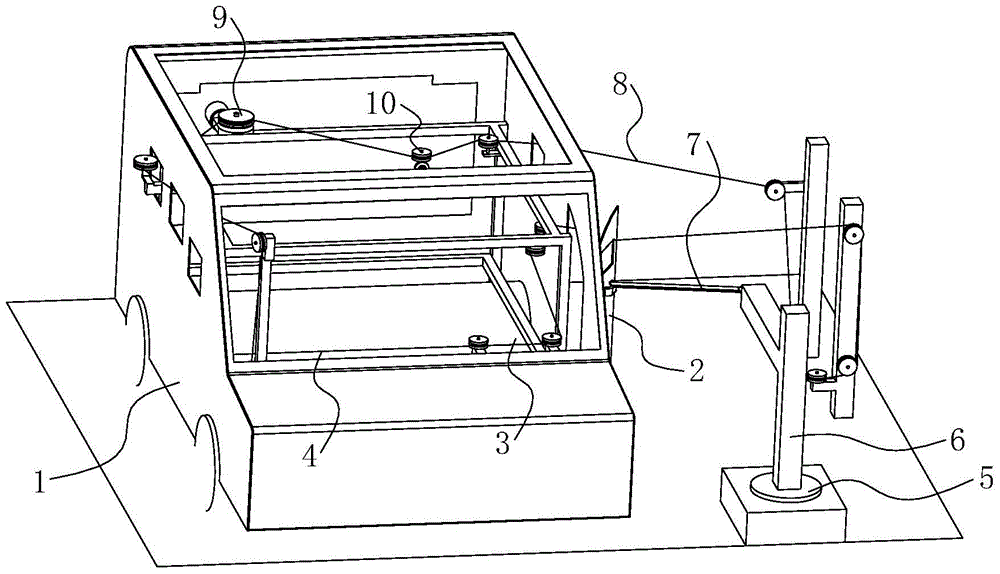

[0026] a kind of like figure 1 The described equipment for automotive PEPS system function and reliability performance test includes:

[0027] The sliding mechanism that carries the smart key and travels in and out of the real vehicle platform 1 to be tested in sequence and at least passes through three test points outside the side door of the main driver's seat 2, the main driver's seat 3, and the auxiliary driver's seat 4 to form a closed loop;

[0028] The smart key in-position detection mechanism is arranged inside and outside the test bench 1 of the actual vehicle and at least arranged on the three test points outside the main driving seat side door 2, the main driving seat 3, and the auxiliary driving seat 4;

[0029] The door opening and closing mechanism and the opening and closing locking mechanism that are installed outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com