A kind of bipolar plate for vanadium battery and preparation method thereof

A bipolar plate, vanadium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of increased surface resistance of bipolar plates, high resistivity of polymer-carbon black composite bipolar plates, and uniform mixing of materials The degree of difficulty is difficult to guarantee and other problems, to achieve the effect of eliminating contact resistance, ensuring reliability, and avoiding uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

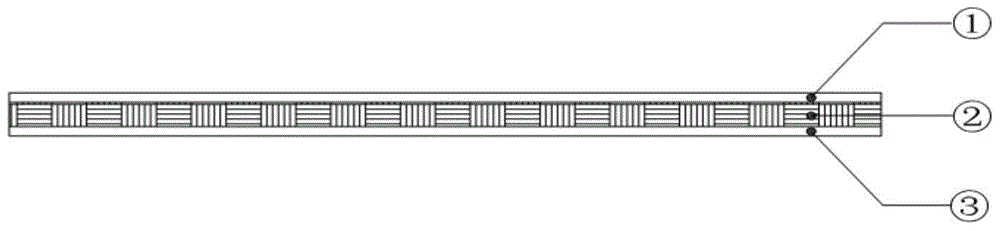

[0026] The preparation method of the bipolar plate for the vanadium battery, the specific steps are as follows:

[0027] 1) The silane coupling agent is made into a dilute solution with a concentration of 0.5-1wt%, the solvent is a solution prepared by water and alcohol, and the solution ratio is silane (20wt%), ethanol (72wt%), water (8wt%), adjust the pH When the value reaches 4-5, immerse the whole carbon fiber cloth in the coupling agent solution for 10-30 minutes, take it out, and dry it at room temperature for later use.

[0028] 2) After mixing synthetic resin and solvent, add metal powder and mix well, then add curing agent to make conductive adhesive;

[0029] 3) Immerse the carbon fiber cloth in the conductive adhesive for 10-60 minutes, take it out and let it stand for 30-120 minutes as a matrix for use;

[0030] 4) Put the carbon material into the bottom layer of the mold, add the matrix and add another layer of carbon material, and make a bipolar plate for vanadi...

Embodiment 1

[0033] Silane coupling agent is made into the dilute solution of 0.5wt% concentration, and solvent is the solution that water and alcohol prepare, and solution ratio is silane coupling agent (20wt%), ethanol (72wt%), water (8wt%), adjust pH When the value reaches 4, immerse the whole carbon fiber cloth in the coupling agent solution for 10 minutes, take it out, and dry it at room temperature for later use. After mixing epoxy resin and acetone, add silver powder and mix thoroughly, then add triethylenetetramine to make conductive adhesive; soak the carbon fiber cloth in the conductive adhesive for 20 minutes, take it out and let it stand for 30 minutes as a matrix for use; take 0.3mm pure Put the graphite powder into the bottom layer of the mold, add the matrix and add a layer of 0.3mm pure graphite powder, and make a bipolar plate for vanadium battery after hot pressing; the hot pressing temperature is 120°C, the hot pressing time is 120min, and the hot pressing pressure is 5MP...

Embodiment 2

[0037] Silane coupling agent is made into the dilute solution of 0.6wt% concentration, and solvent is the solution that water and alcohol prepare, and solution ratio is silane coupling agent (20wt%), ethanol (72wt%), water (8wt%), adjust pH When the value reaches 5, immerse the whole carbon fiber cloth in the coupling agent solution for 20 minutes, take it out, and dry it at room temperature for later use. After mixing epoxy resin and ethanol, add copper-coated silver powder, mix thoroughly, and then add ethylenediamine to make a conductive adhesive; soak the carbon fiber cloth in the conductive adhesive for 30 minutes, take it out and let it stand for 40 minutes as a matrix for use; take 1mm carbon Put the black into the bottom layer of the mold, add the matrix and add another layer of 1mm carbon black, and make a bipolar plate for vanadium battery after hot pressing; the hot pressing temperature is 160°C, the hot pressing time is 180min, and the hot pressing pressure is 10MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com