Fixing frame for connector module

A technology of connector modules and fixed frames, which is applied in the direction of connection, installation of connection parts, parts of connection devices, etc., can solve the problems of inconvenient loading and unloading of connector modules, and achieve convenient and quick loading and unloading, reasonable design, and reduced complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

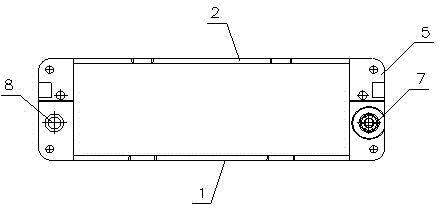

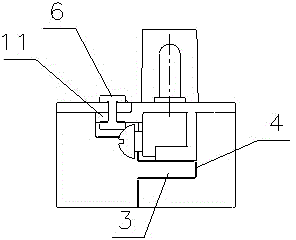

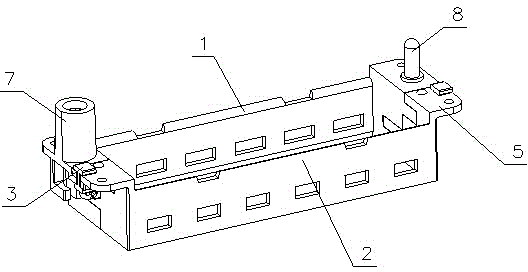

[0018] see Figure 1-6 As shown, a connector module fixing frame includes a left frame body 1 and a right frame body 2. The left and right frame bodies 1 and 2 are spliced together to form a rectangular frame with an upper end opening. There are corresponding sockets 4 and protrusions 3 on the right frame body 2, and the protrusions 3 are correspondingly inserted into the corresponding sockets 4.

[0019] On both sides of the left and right frame bodies 1 and 2, there are corresponding outward flanges 5, and the flanges 5 are overlapped at the joints, openings are correspondingly opened at the overlapping positions, and the "I"-shaped connecting blocks 6 are clamped at the openings, Thereby the left and right frame bodies 1, 2 are connected and fixed together.

[0020] In order to avoid interference with other components, the top surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com