Dumping device of harvester

A technology of dumping device and harvester, which is used in loaders, agricultural machinery and implements, applications, etc., can solve the problems of poor control of the dumping angle of dumping and unloading, inability to pour grain into a designated position, and outlet blockage, etc., and achieves a simple structure. , easy to start, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

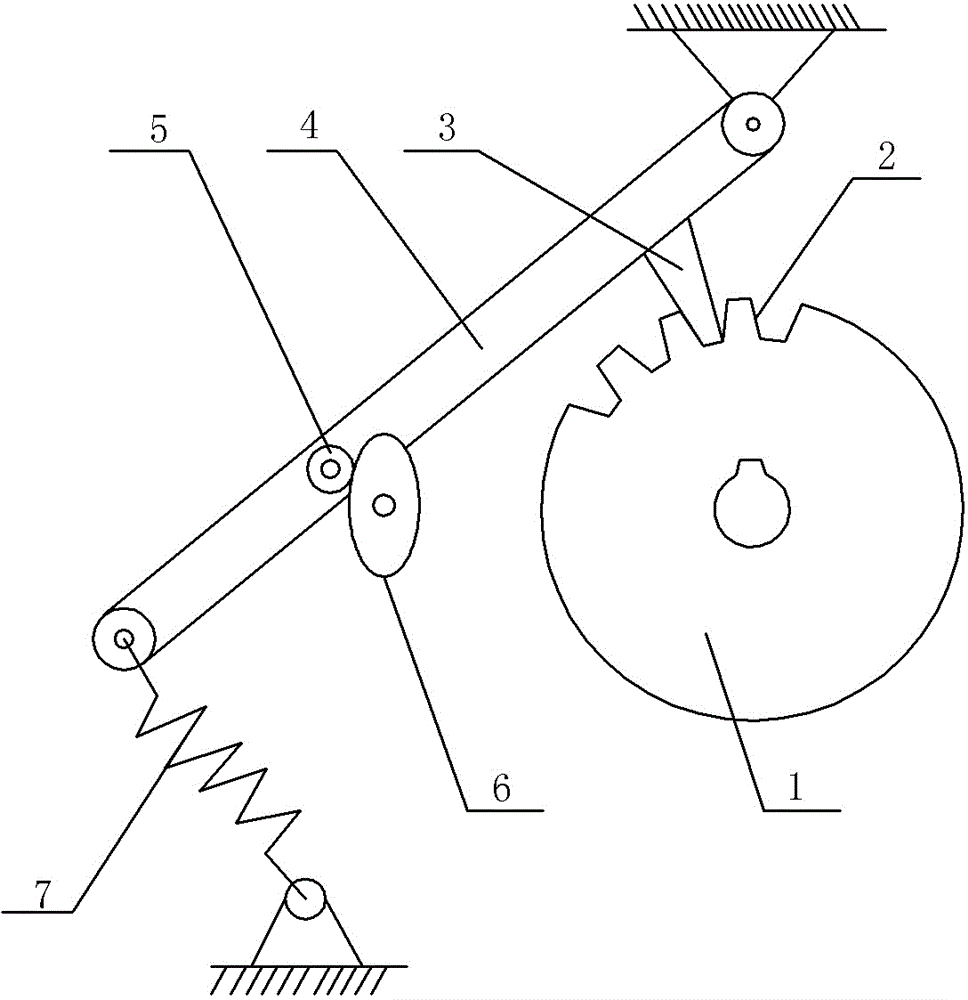

[0011] Instructions attached figure 1 The reference numerals in include: chuck 1 , latch 2 , claw 3 , control rod 4 , driven post 5 , cam 6 , and return spring 7 .

[0012] The embodiment is basically as attached figure 1 Shown: the dumping device of the harvester, including the frame, the chuck 1 coaxial with the rotation axis of the storage bucket on the frame and connected with the key. A card slot is formed between them, and the storage bucket drives the chuck 1 to rotate while turning over.

[0013] A control rod 4 is installed on the inclined surface of the chuck 1, the upper end of the control rod 4 is hinged with the frame through a cylindrical pin, and the lower end of the control rod 4 is connected with the frame through a return spring 7, and the shaft of the return spring 7 The direction is at an angle of 90° to the axis of the control rod 4, and the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com