Side core-pulling mechanism and injection mould

A side core-pulling and guiding mechanism technology, which is applied in the field of side core-pulling mechanisms and injection molds, can solve problems such as product deformation, achieve the effects of preventing deformation of plastic parts, improving pass rate, and ensuring molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

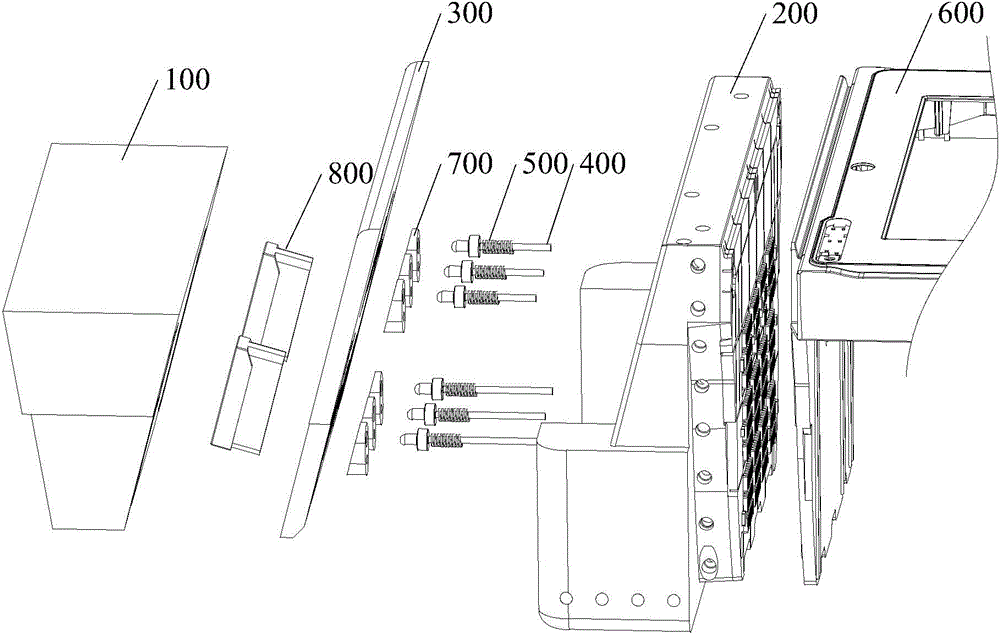

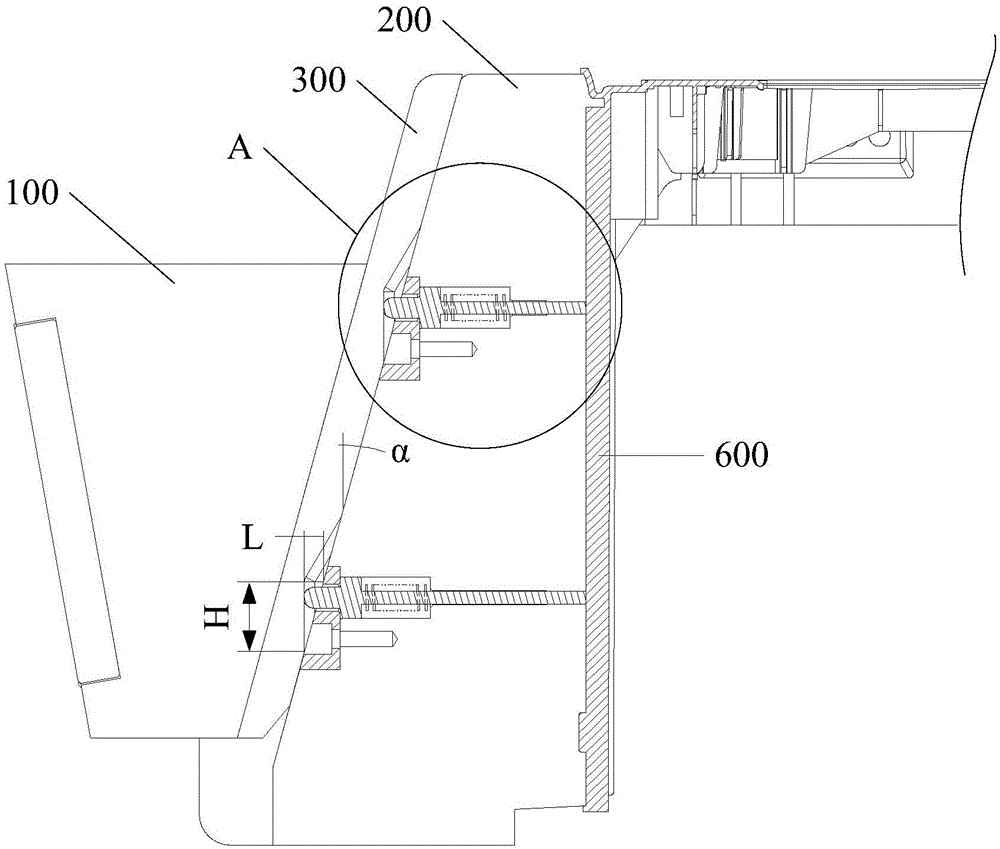

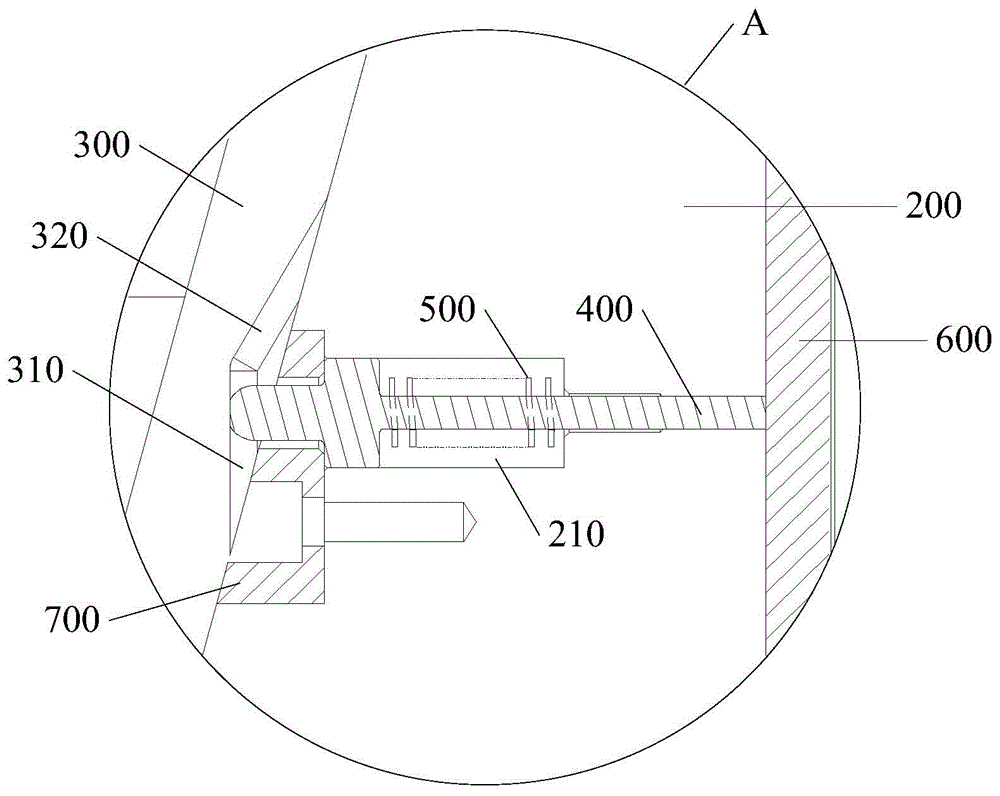

[0022] The invention provides a side core pulling mechanism, see Figure 1 to Figure 5 , in one embodiment, the side core-pulling mechanism includes a shovel base 100 and a slider 200 that are slidably matched. When the mold is closed, the shovel base 100 wedges the slider 200 tightly through the wedge-shaped surface matched with the slider 200; When opening the mold, the shovel base 100 drives the slider 200 to withdraw backward through the slider chute guide mechanism arranged between it and the slider 200 and can keep the two in linkage, so as to realize core pulling.

[0023] Wherein, the slider 200 is provided with a thimble hole 210 communicating with the cavity (the cavity is formed by the slider 200 and other parts of the injection mold), and the thimble hole 210 runs through the left and right sides of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com