Improved fluid bottle cap

A bottle cap and liquid technology, applied in the field of food and medicine containers and improved liquid bottle caps, can solve the problems of high production cost, short shelf life, human health impact, etc., and achieve the effect of reducing costs and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

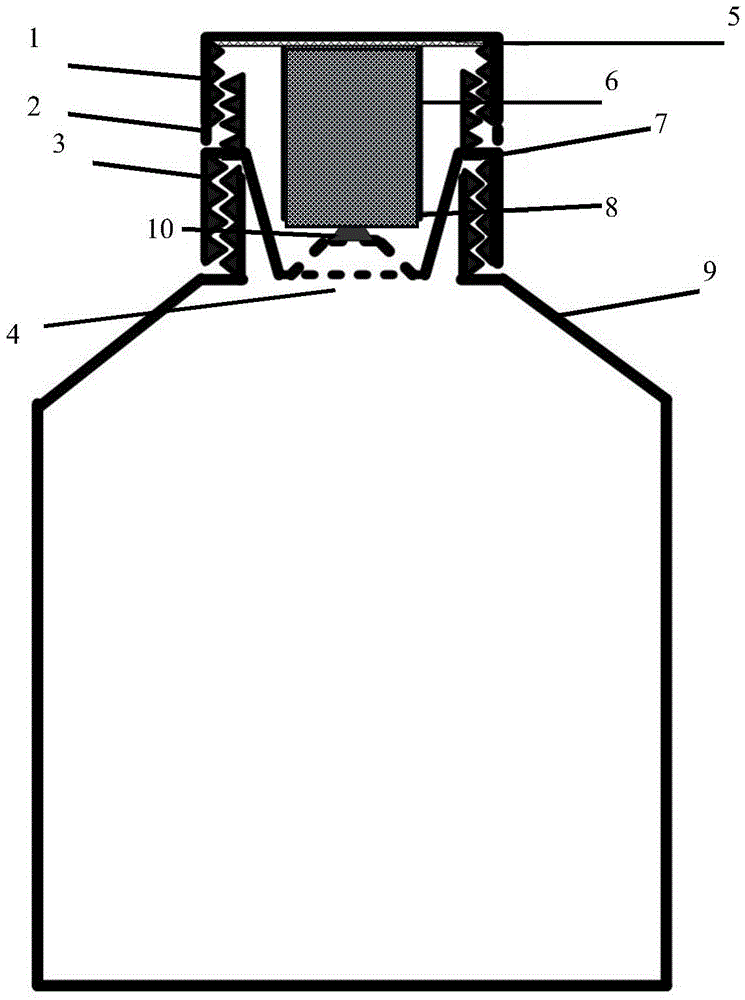

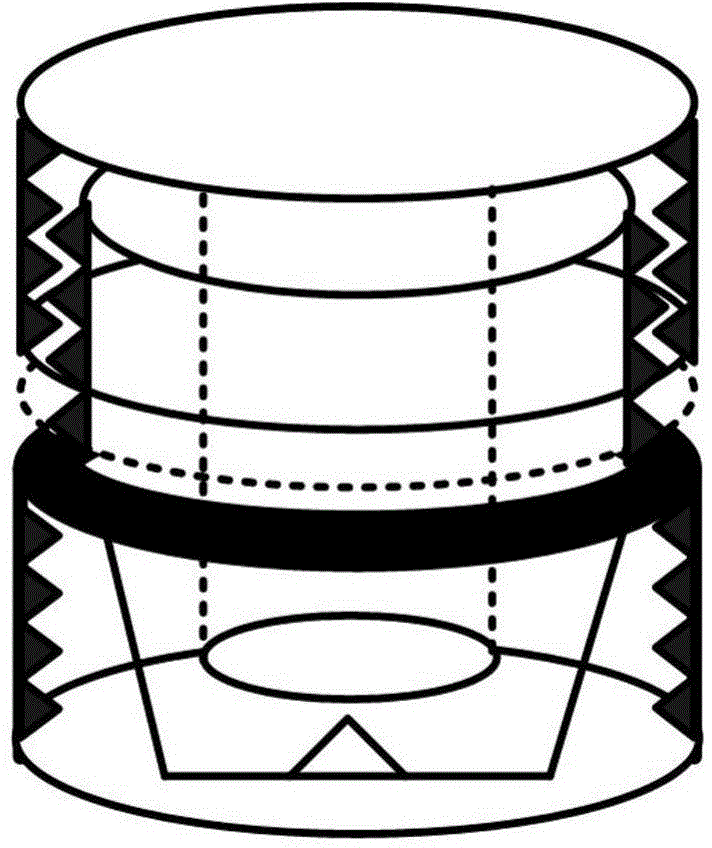

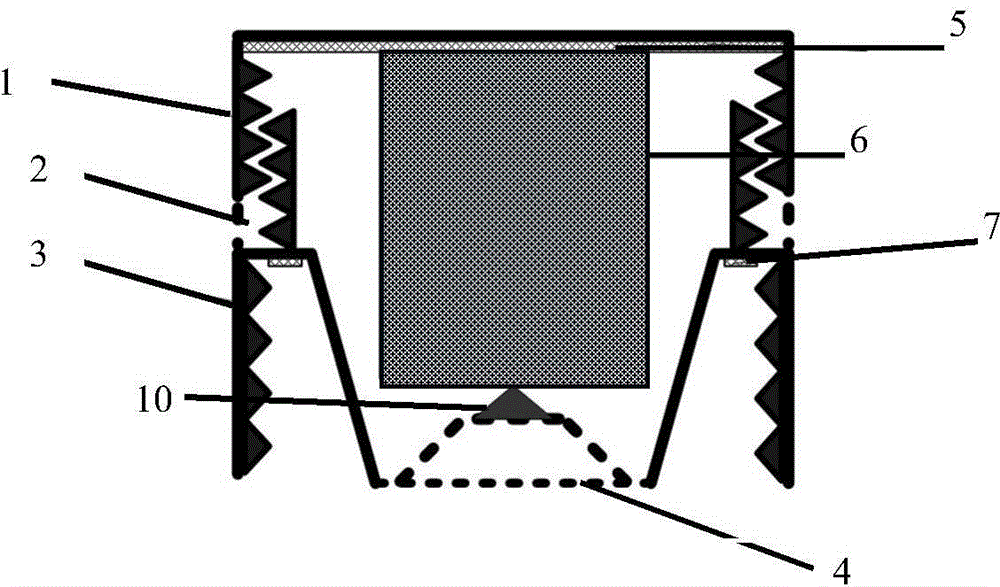

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, an improved liquid bottle cap of the present invention comprises an upper cover 1, the inner side of the side wall of the upper cover 1 is provided with internal threads, and a lower cover 3, the side of the lower cover 3 The inner side of the wall is provided with internal threads, and the upper cover 1 and the lower cover 3 are connected by a pull ring 2, and the inside of the upper cover 1 is provided with a closed material storage container 6, the One end of the storage container 6 is fixedly connected to the upper cover 1, the other end of the storage container 6 is provided with a layer of sealing film 8, and the lower cover 3 is provided with a feeding port 4, so The above-mentioned material opening 4 communicates with the upper side and the lower side of the lower cover 3, and the lower cover 3 is provided with a sharp object 10 protruding upwards, and the said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com