Disorder rope monitoring system for winding reel of mine hoist and disorder rope judging method

A mine hoist and monitoring system technology, which is applied in the direction of elevators, hoisting devices, clockwork mechanisms, etc., can solve the problems of inability to judge and monitor steel wire ropes, achieve low cost, ensure safe operation, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiments: The present invention includes a monitoring system and a monitoring method.

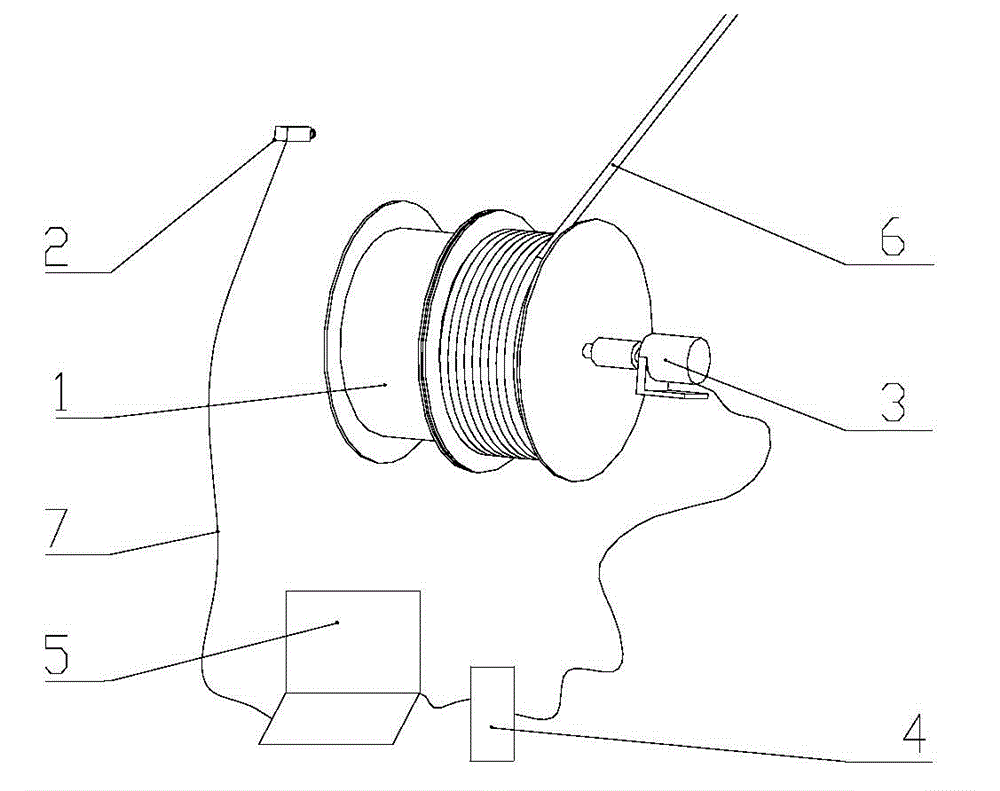

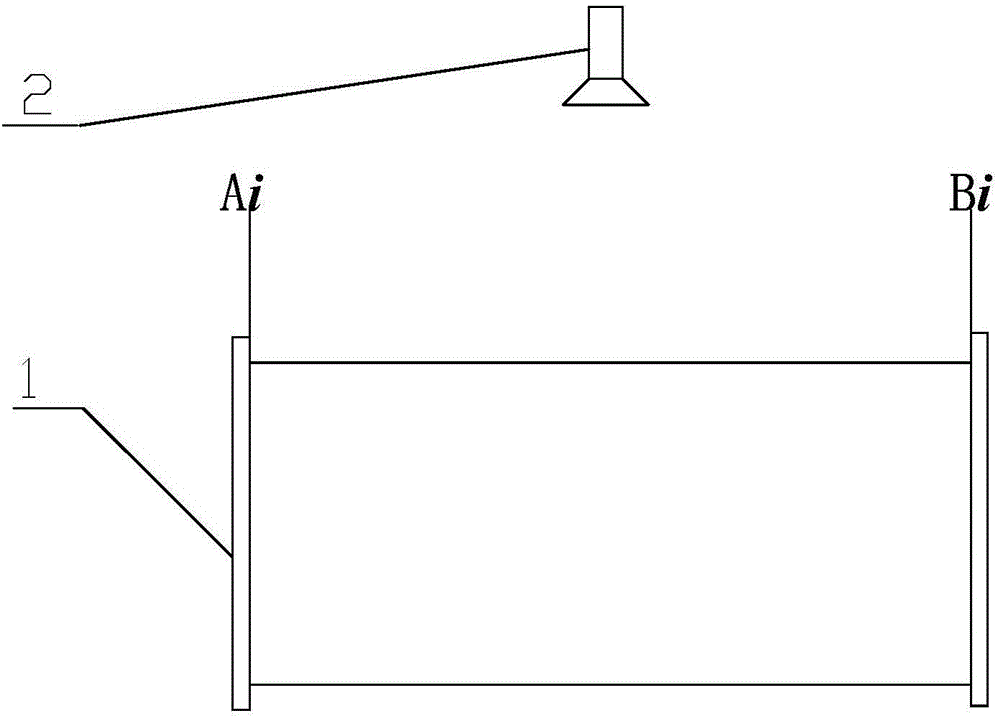

[0029] figure 1 It is a layout diagram of a wire rope drum monitoring system for a mine hoist according to the present invention. The monitoring system includes: an industrial camera 2 installed at the upper rear or lower front of the rope in the middle of the reel 1, a shaft encoder 3 installed at the shaft end of the reel 1 and connected to the shaft, and data that is sequentially connected to the shaft encoder 3 The acquisition card 4 and the industrial computer 5 ; the industrial camera 2 is connected to the industrial computer 5 through a cable 7 .

[0030] A method for judging the rope disorder of a mine hoist wire rope drum, specifically:

[0031] 1) The industrial computer 5 sets the judgment cycle T, the same sampling times n of the industrial camera 2 and the shaft encoder 3 within the judgment cycle T, that is, each sampling interval time Δt=T / n, and sets m·Δt as Sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com