Test device and test method used for testing three-dimensional strained condition

A strain state and testing device technology, applied in measuring devices, instruments, etc., can solve problems such as the inability to calculate the strain state in three-dimensional space, one-sided and incomplete strain state data, etc., and achieve the effect of reasonable structure, convenient operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

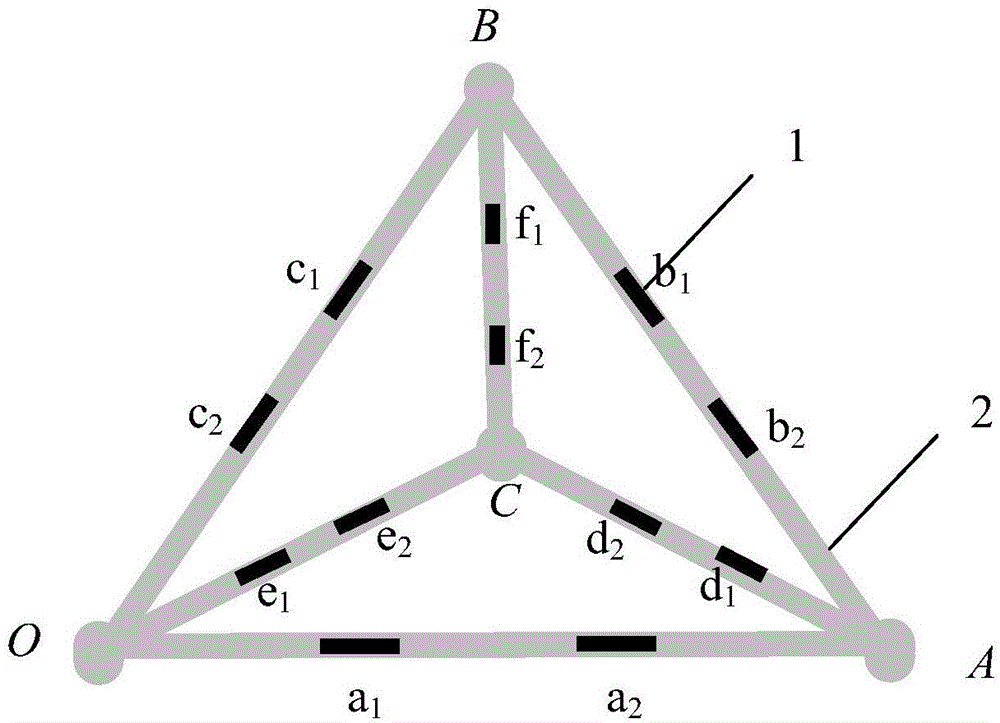

[0078] Example: Measuring the strain state of a cohesive soil during frost heaving / thawing

[0079] During the construction of the subway communication channel, the frost heaving and thawing of the soil has a great impact on the stability and safety of the subway communication channel. At present, the displacement change can only be observed by setting displacement monitoring points on the surface, but the stress-strain change of the internal soil cannot be effectively measured. In this experiment, three-dimensional strain rosettes are embedded in clay to measure the strain change of a certain clay during frost heaving / thawing. The obtained test data and related analysis can provide certain reference significance for related construction safety. The test method is as follows: dry a certain clay in an oven, prepare soil samples with different dry densities and different moisture contents, and place them together with the three-dimensional strain rosette in a 150*150*150mm 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com