Three-dimensional detection method, three-dimensional detection device and three-dimensional detection system for connector contact pin

A technology for three-dimensional inspection and connectors, which is applied in the direction of optical testing for flaws/defects, and can solve problems such as slow manual inspection, error in inspection results, and difficult quantitative inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

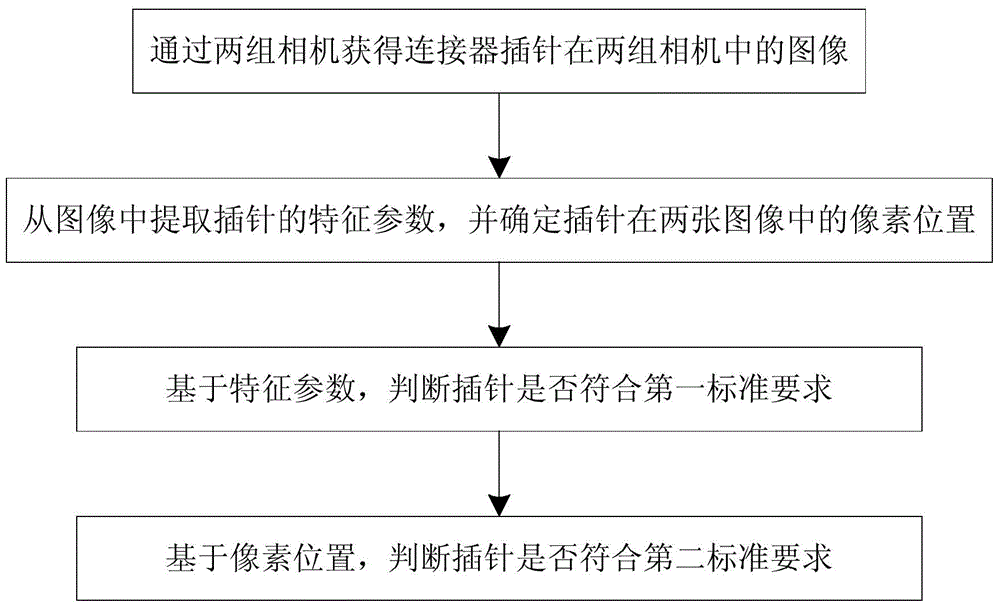

[0043] figure 1 It is a schematic flow chart of a three-dimensional detection method for connector pins 2 provided by a specific embodiment of the present invention. like figure 1 As shown, a three-dimensional detection method for a connector pin 2 according to the present invention includes:

[0044] Obtain images of connector pin 2 in two sets of cameras through two sets of cameras;

[0045] Extract the feature parameters of the pins from the images, and determine the pixel positions of the pins in the two images;

[0046] Based on the characteristic parameters, it is judged whether the contact pin meets the requirements of the first standard;

[0047] Based on the pixel position, it is judged whether the pin meets the requirements of the second standard.

[0048] It can be seen that this solution can realize efficient, stable and quantitative automatic detection of connector pins 2, and solve the problems of slow manual inspection, difficulty in stable quantitative dete...

Embodiment 2

[0060] The following is the device embodiment of the embodiment of the present invention. The method embodiment and the device embodiment of the present invention belong to the same concept. For details not described in detail in the device embodiment, you can refer to the above method embodiment.

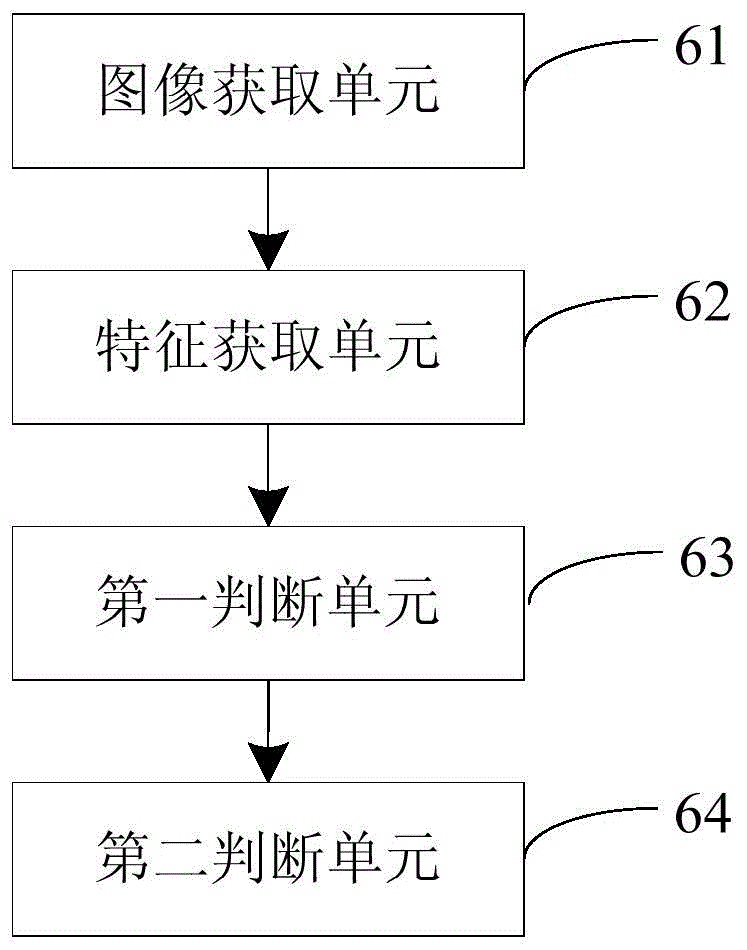

[0061] figure 2 It is a schematic structural diagram of a three-dimensional detection device for connector pins 2 provided by a specific embodiment of the present invention. like figure 2 As shown, a connector pin 2 three-dimensional detection device according to the present invention includes:

[0062] An image acquiring unit 61, configured to acquire the images of the connector pin 2 in the two sets of cameras through the two sets of cameras;

[0063] The feature acquisition unit 62 is used to extract the feature parameters of the pins from the images, and determine the pixel positions of the pins in the two images;

[0064] The first judging unit 63 is configured to judge w...

Embodiment 3

[0074] The following is the system embodiment of the embodiment of the present invention. The method embodiment and the system embodiment of the present invention belong to the same concept. For details not described in detail in the system embodiment, you can refer to the above method embodiment.

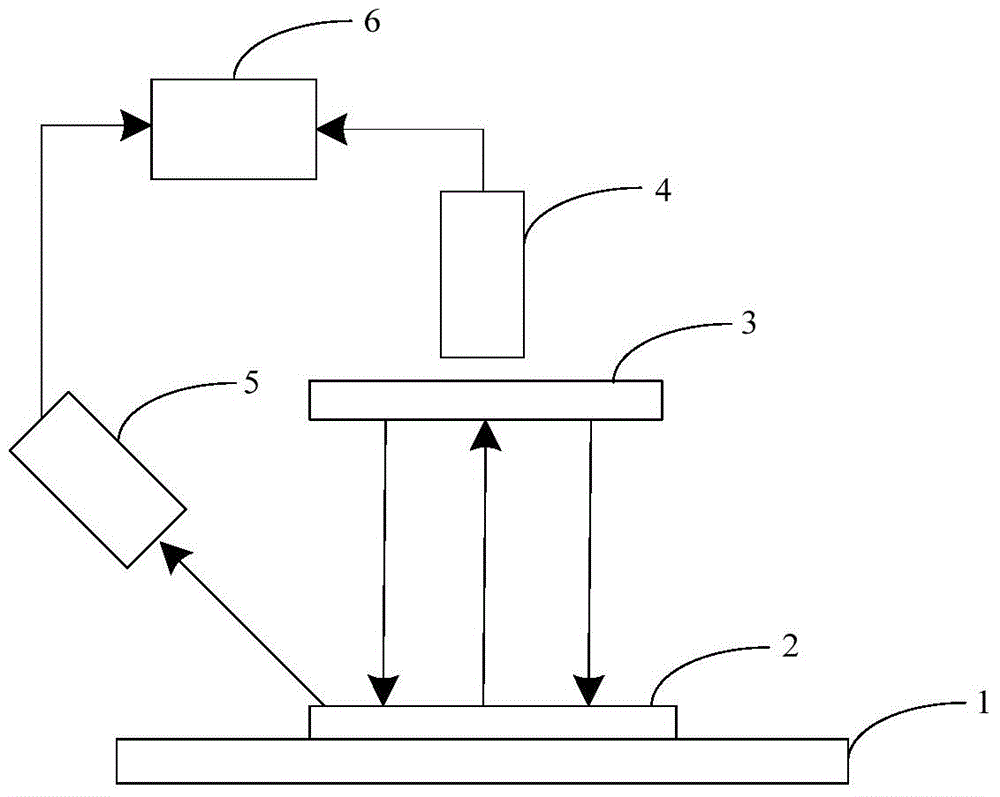

[0075] image 3 It is a structural schematic diagram of a three-dimensional detection system for connector pins 2 provided by a specific embodiment of the present invention. like image 3 As shown, a three-dimensional inspection system for connector pins 2 according to the present invention includes: a first camera 4, a second camera 5, a light source 3, and a stage 1 for placing connector pins 2. The first camera 4 and the second camera 5 are arranged at an angle, the optical axis of the first camera 4 is perpendicular to the plane of the stage 1, and the light source 3 is used to vertically illuminate the connector placed on the stage 1 The pin 2, the first camera 4 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com