Core wire size non-contact type visual detection device and method for automobile wire harness

A non-contact, automotive wiring harness technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of low detection efficiency and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

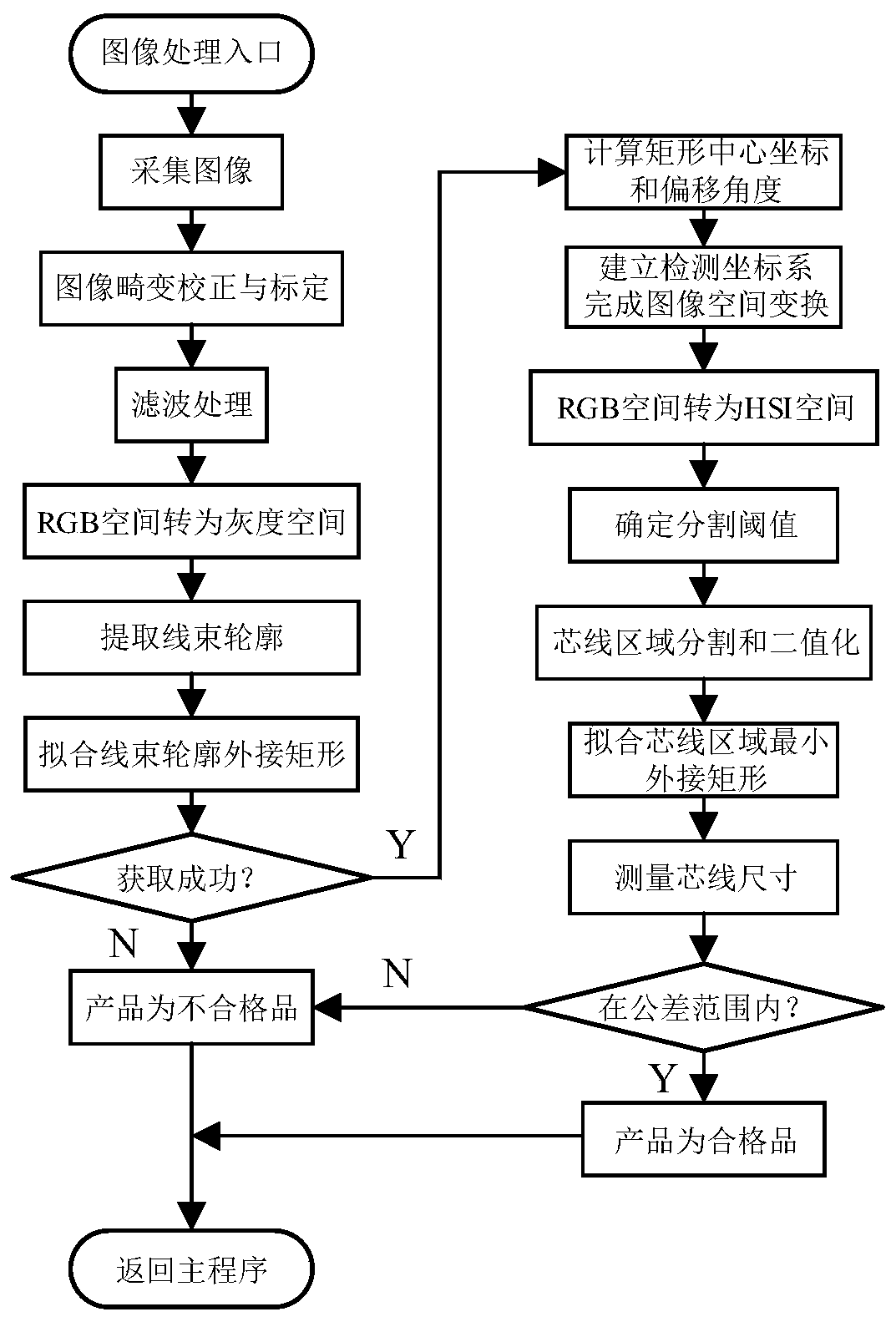

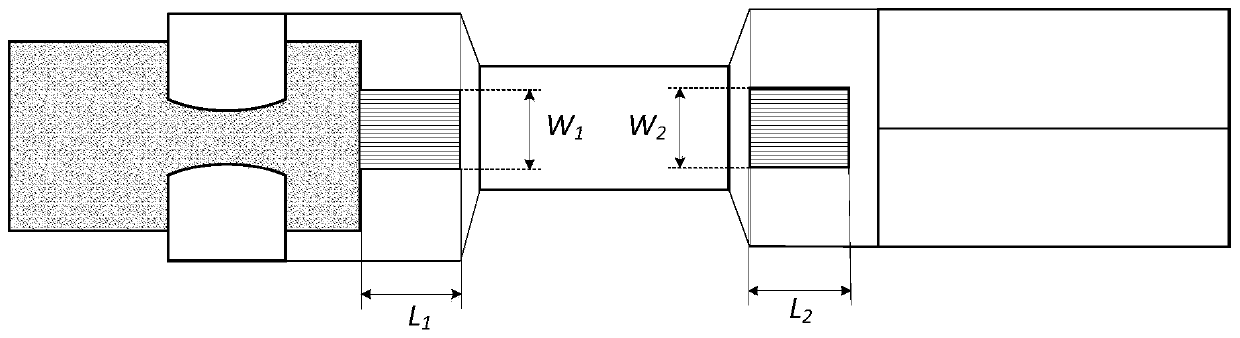

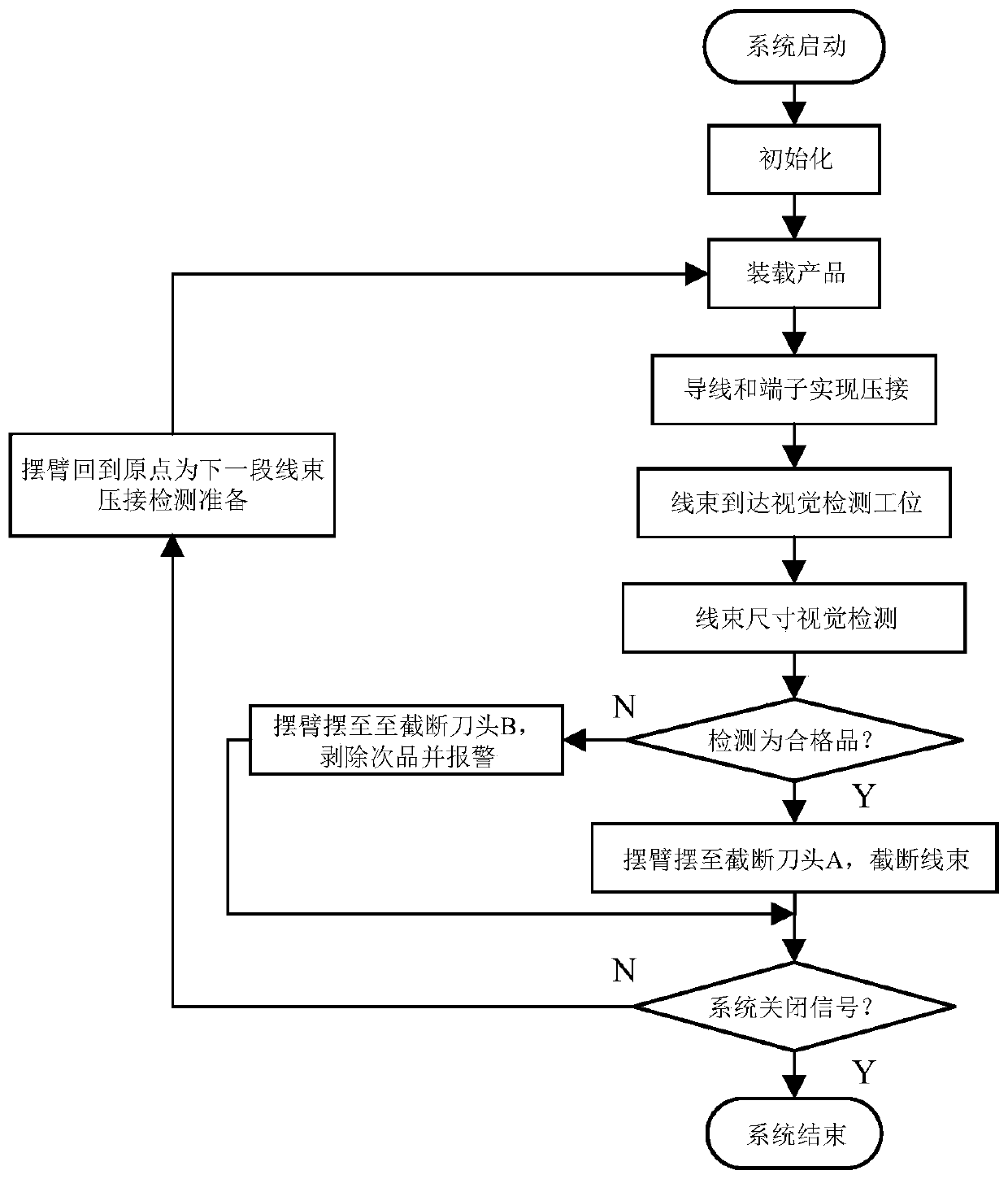

[0069] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

[0070] First, transmit the terminal barcode read by the code reader A6 and the wire 12 barcode read by the code reader B11 to the host computer. After the host computer judges that the barcode models match, the operator completes the loading of the wire 12 and starts the equipment according to the process. , start running the production inspection station. The wire 12 enters the guide tube in the swing arm 14 through the wire feeding belt 10, and the wire 12 is driven by the swing arm 14 to the crimping machine 8 to complete the crimping of the wire harness 15. When the swing arm 14 swings to the visual inspection station, the photoelectric sensor is sequentially triggered. Sensor A4 and photoelectric sensor B5, PLC20 receives the sequence control signal for logical processing, and then sends corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com