Fuel assembly blending screenwork with rectifying type blending wings

A fuel assembly and mixing wing technology, applied in the field of reactor components, can solve the problems of increasing kinetic energy dissipation, weakening, disturbance, etc., and achieve the effects of improving thermal margin, reducing diversion, and increasing mixing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

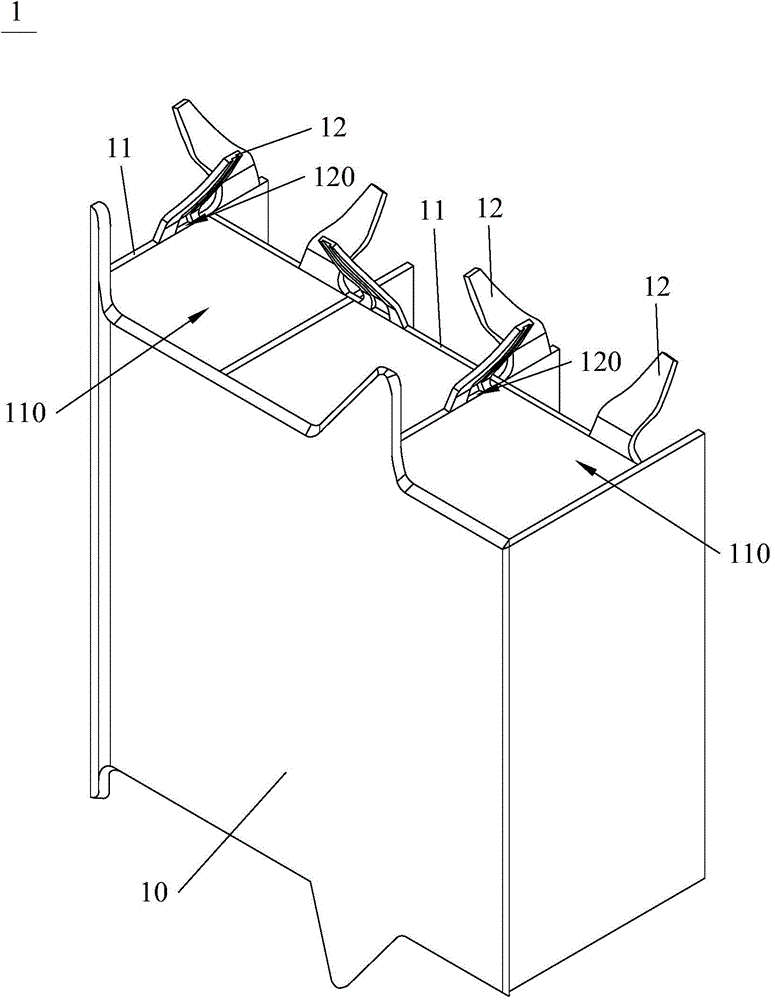

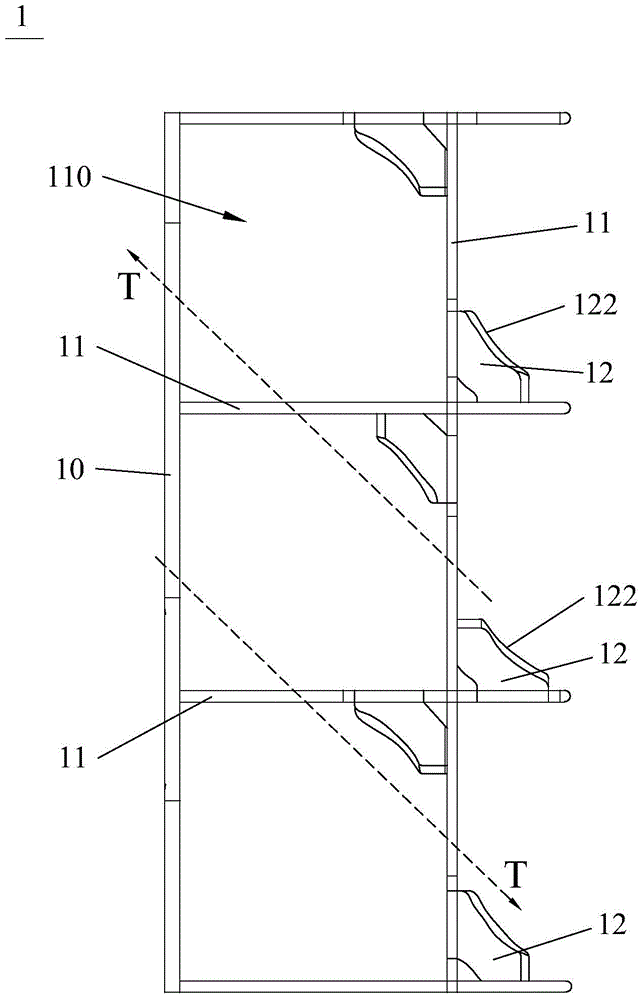

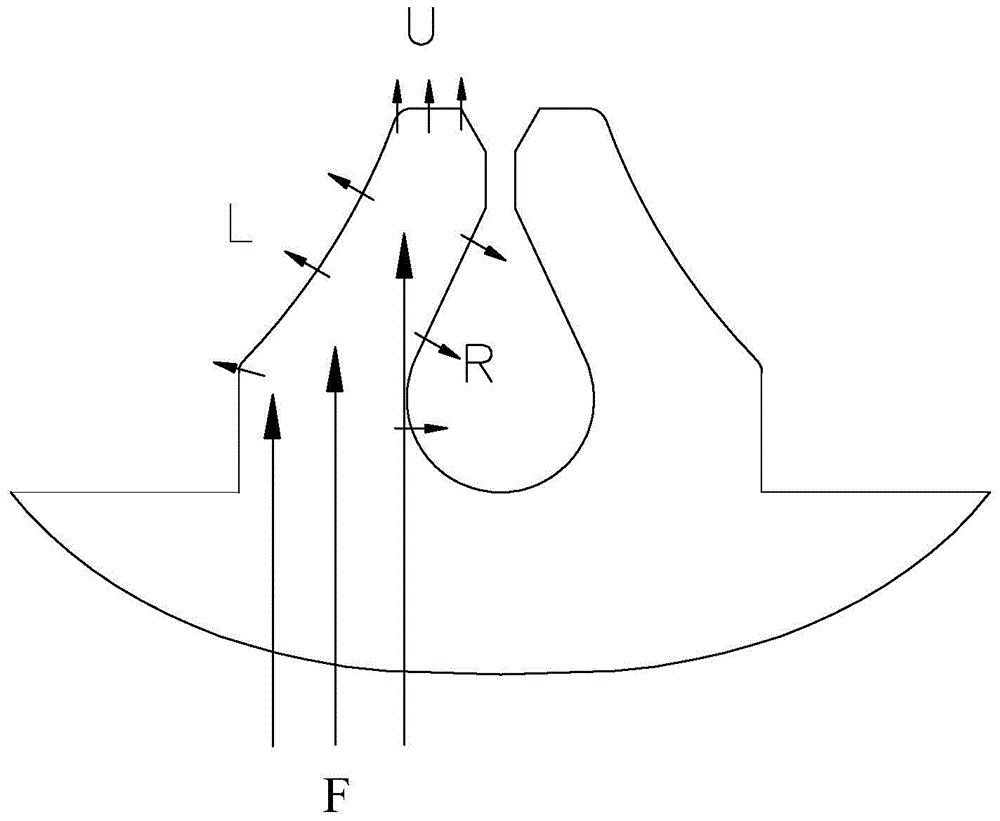

[0030] like figure 1 , figure 2 As shown, the fuel assembly stirring grid 1 with a rectifying type stirring blade of the present invention includes an outer strip 10 and a plurality of inner strips 11, and a plurality of the inner strips 11 intersect with each other to form a grid structure, and the grid structure There are a plurality of hollow grid units 110, the outer strip 10 surrounds the outer periphery of the grid structure and is fixed with the inner strip 11, the grid structure has a plurality of stirring wings 12, the stirring The wings 12 extend into the grill unit 110 , and a guide groove 120 is provided on the side of the stirring wing 12 facing the grill unit 110 .

[0031] The inner strips 11 are actually divided into two groups. One group of inner strips 11 is arranged parallel to each other and at equal intervals, and the other g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com