Thermal storage material composition, auxiliary heat source and heat supply method using the thermal storage material composition

一种蓄热材料、组合物的技术,应用在热交换的材料、化学仪器和方法、蓄热设备等方向,能够解决结晶速度慢等问题,达到热能储存稳定性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

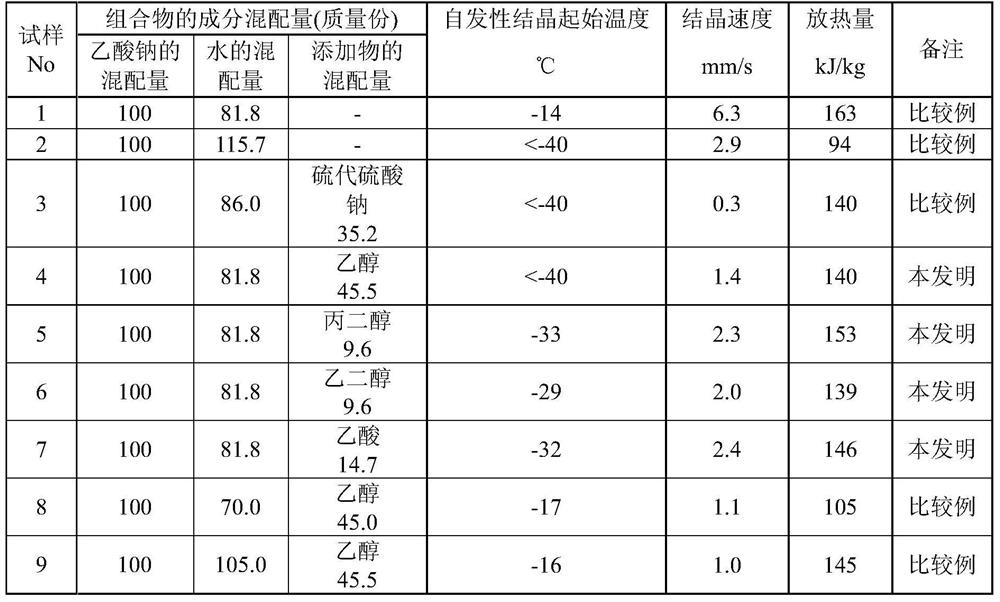

[0069] Each heat storage material sample whose total heat storage material was 4g was produced using the heat storage material composition of following Table 1.

[0070] The following items of these respective samples were measured.

[0071] (Determination of spontaneous crystallization initiation temperature)

[0072] 4 g of each sample (heat storage material) was sealed in an airtight container, and after melting at 80° C., it was cooled to room temperature to be in a supercooled state. Thereafter, a thermocouple was attached, and after that, it was set in a constant temperature bath, and the temperature of the atmosphere was lowered at a rate of about 0.7°C / minute, and cooled to -40°C. The temperature change of the thermal storage material was observed with a thermocouple, and the temperature at which a sudden temperature rise due to crystallization occurred was taken as the spontaneous crystallization initiation temperature.

[0073] (Measurement of crystallization speed...

Embodiment 2

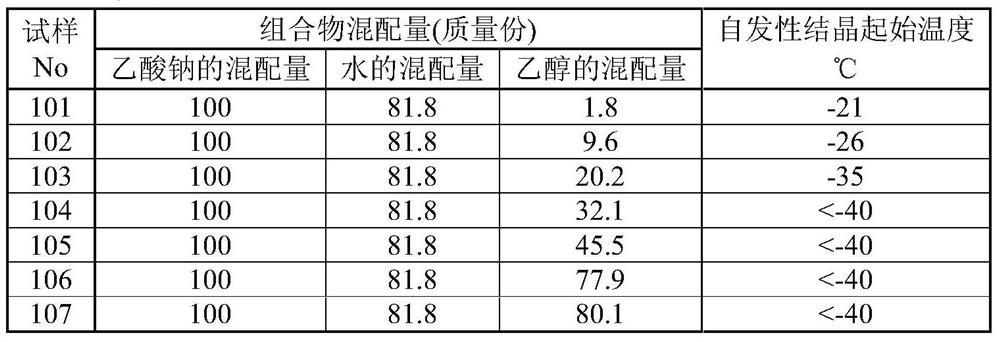

[0085] The addition amount dependence of ethanol was evaluated.

[0086] The obtained results are shown in Table 2.

[0087] 【Table 2】

[0088]

[0089] In addition, the sample 105 is the same sample as the sample 4 of Table 1.

[0090] Here, the crystallization speeds of samples 102, 104, and 105 were 2.9 mm / s, 1.6 mm / s, and 1.4 mm / s in this order.

[0091] The spontaneous crystallization initiation temperature of samples 102 to 107 was -25°C or lower.

[0092] In samples 101 to 106, the crystallization rate was 0.6 mm / sec or more, and the heat dissipation was 130 kJ / kg or more.

[0093] The crystallization rate of sample 107 was less than 0.6 mm / sec, and the heat release was less than 130 kJ / kg.

Embodiment 3

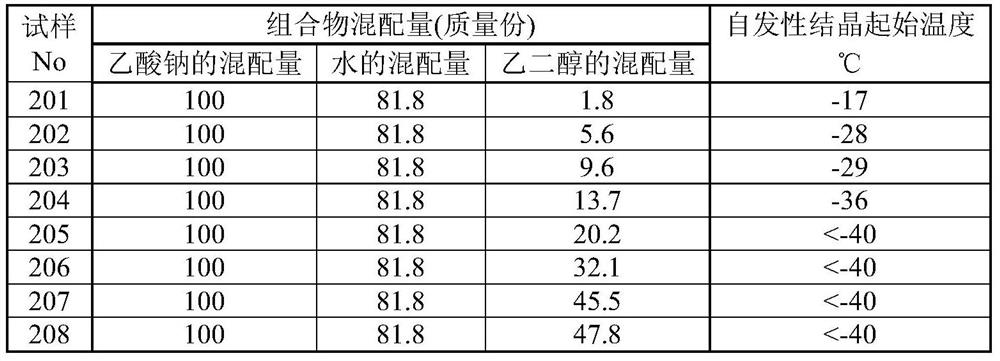

[0095] The addition amount dependence in the case of ethylene glycol was evaluated in the same manner as in Example 2.

[0096] The obtained results are shown in Table 3.

[0097] 【table 3】

[0098]

[0099] The spontaneous crystallization initiation temperatures of samples 202 to 208 were all below -25°C. The spontaneous crystallization onset temperature of sample 201 was higher than -25°C.

[0100]In samples 201 to 207, the crystallization rate was 0.6 mm / sec or more. The crystallization rate of sample 208 was less than 0.6 mm / sec.

[0101] The heat dissipation of samples 201 to 208 was 130 kJ / kg or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com