Secondary sleeve reshaping mould and secondary sleeve reshaping method

A technology of secondary shaping and sleeves, applied in the direction of sewing tools and other directions, can solve the problem of easy creases and imprints on sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

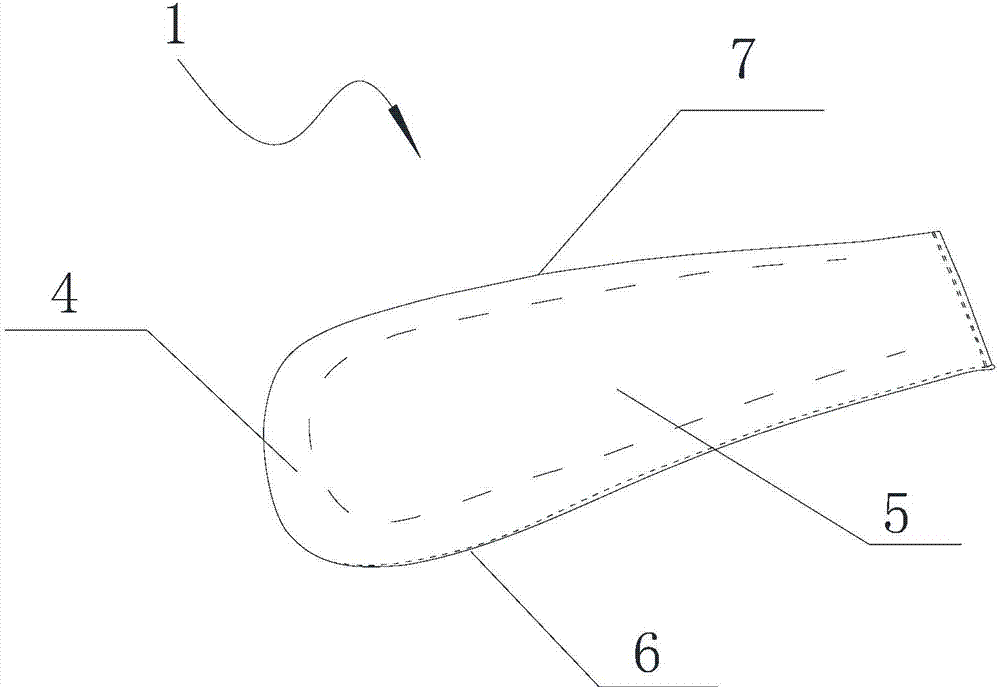

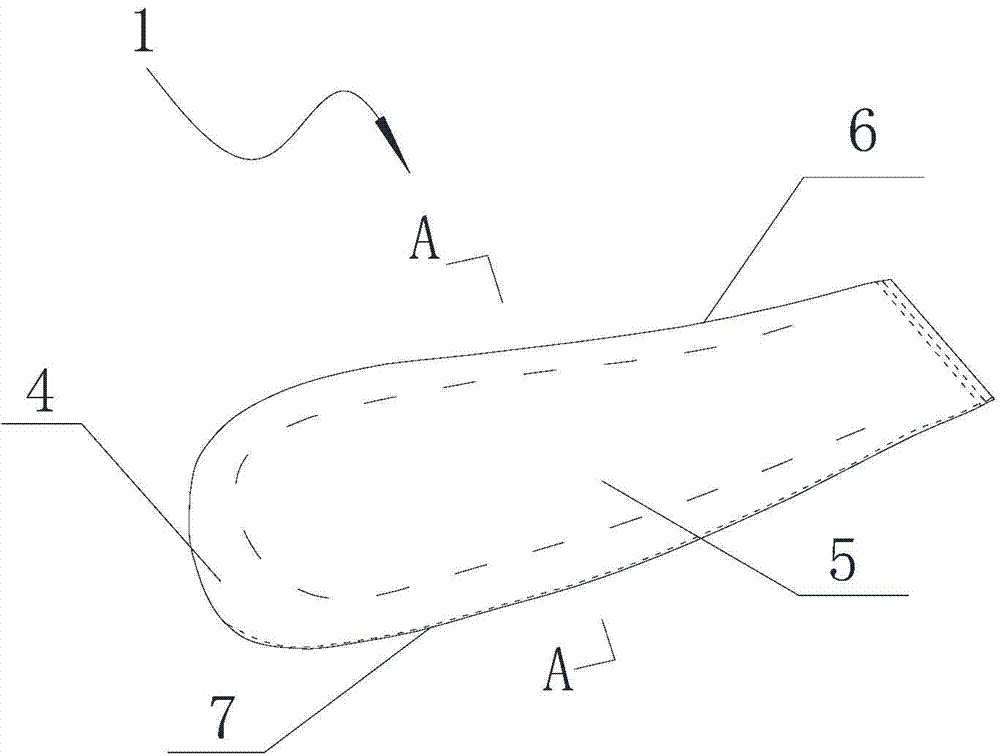

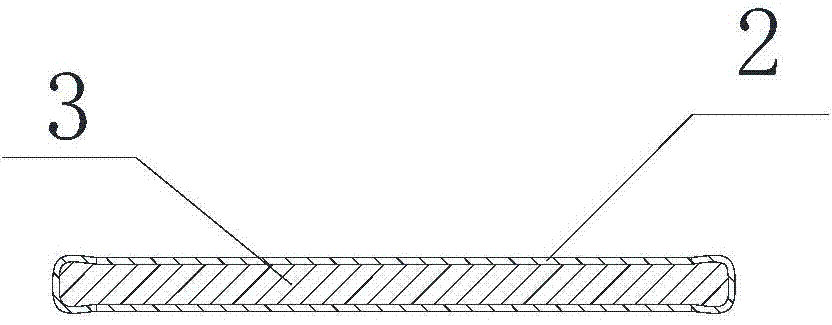

[0020] figure 1 It is a schematic structural view of the front of the sleeve secondary shaping mold according to an embodiment of the present invention, figure 2 It is a structural schematic diagram of the reverse side of the sleeve secondary shaping mold according to an embodiment of the present invention, image 3 for figure 1 The cross-sectional view of the sleeve secondary plastic mold in A-A line, Figure 4 It is an implementation state diagram when the sleeve secondary shaping mold of an embodiment of the present invention is used for sleeve secondary shaping. Such as Figure 1-Figure 4 As shown, the sleeve secondary shaping mold 1 of the present invention includes a sheet-shaped inner core 3 and an outer jacket 2 that wraps the inner core 3 snugly. The length of the mold 1 is not less than the length of the sleeve 8, and the width of the mold 1 is 1cm-2cm larger than the width of the sleeve 8 when laid flat. The thickness of the mold 1 is 0.8cm-1.2cm. The length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com