Composite metal steel plate for solar battery pure subline printing

A solar cell and composite metal technology, applied in printing, printing machine, printing process and other directions, can solve the problems of affecting the precision of graphic precision printing, difficult to control the weaving screen plate, and misalignment of the weaving screen plate, so as to achieve good application prospects. , The effect of improving solar energy conversion efficiency and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

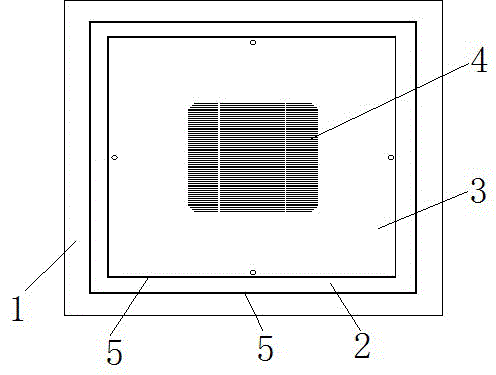

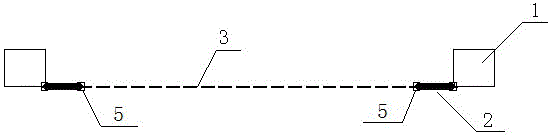

[0024] Such as figure 1 As shown, the composite metal steel sheet for pure secondary line printing of solar cells of the present invention includes a single-layer metal film 3 and a frame 1 for peripheral positioning. The protective effect of the metal film 3, the single-layer metal film body 3 is provided with several sub-wires 4 of the positive electrode of the solar cell, and the several sub-wires 4 are elongated and evenly distributed on the single-layer metal film body 3. The metal film 3 is processed by electroforming nickel alloy sheet, laser-cut stainless steel sheet or chemically etched metal sheet. It has the characteristics of high surface hardness, excellent brush resistance and solvent resistance. The single-layer metal film 3 The thickness is between 20 and 60 microns, and the thickness of the single-layer metal film 3 is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com