Optical fingerprint sensor structure and electronic device

A fingerprint sensor and electronic equipment technology, applied in chemical instruments and methods, instruments, coatings, etc., can solve problems such as print marks on photosensitive films, and achieve the effect of improving accuracy and beautiful structure of optical fingerprint sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

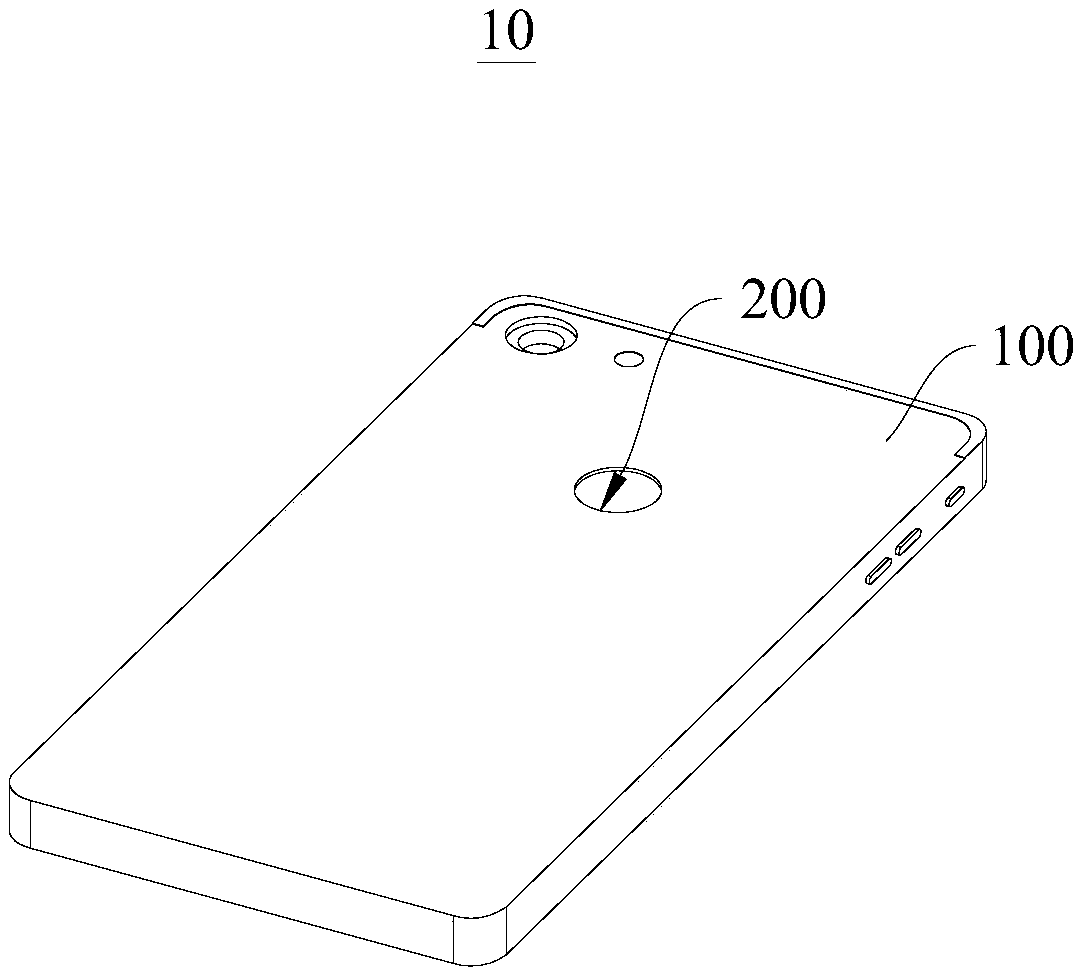

[0034] see figure 1 , this embodiment provides an electronic device 10 , the electronic device 10 includes an electronic device body 100 and an optical fingerprint sensor structure 200 , and the optical fingerprint sensor structure 200 is disposed on the electronic device body 100 .

[0035] The electronic device 10 can be any device that can support the optical fingerprint sensor structure 200. For example, the electronic device 10 can be a mobile phone, a tablet computer, a notebook computer or other electronic devices 10. In this embodiment, the electronic device 10 can be a mobile phone, but is not limited to this.

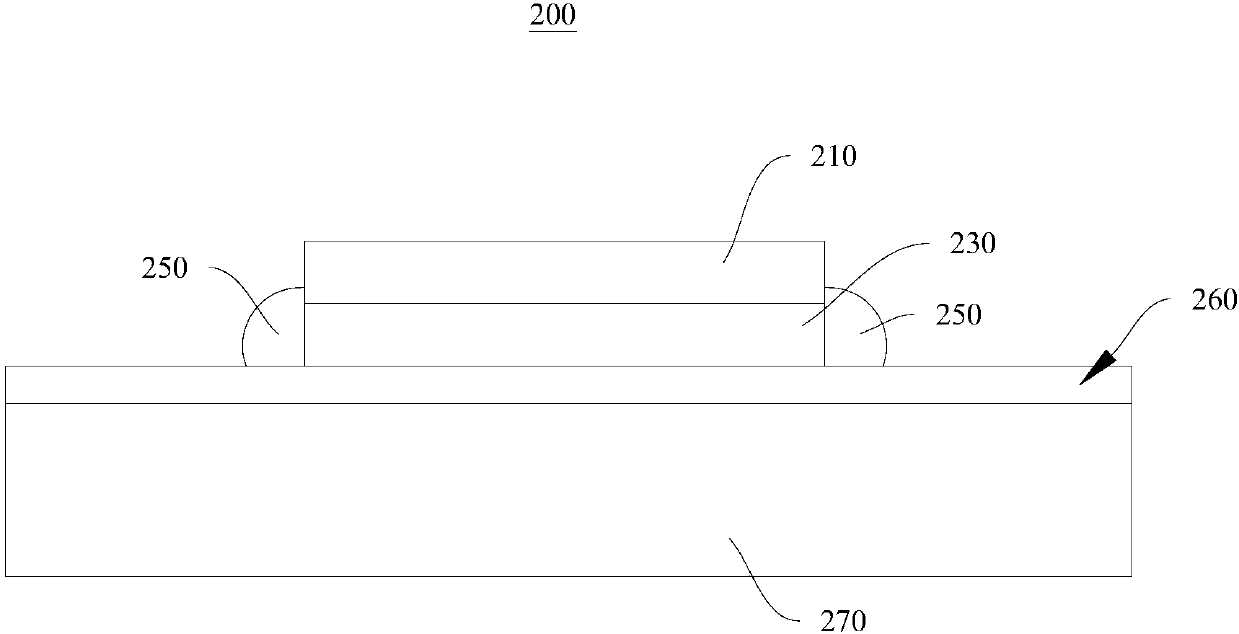

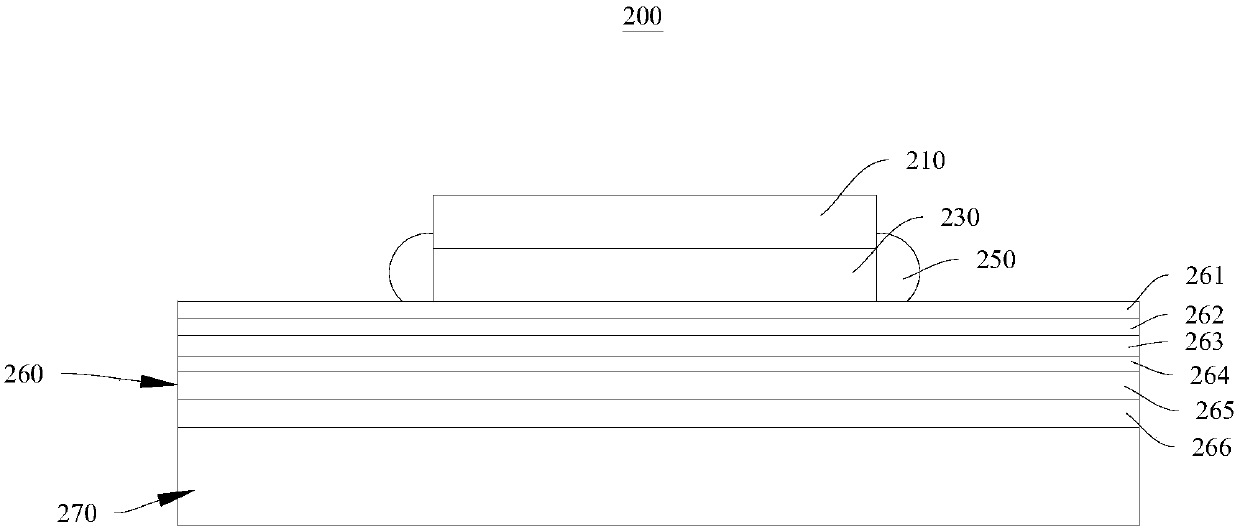

[0036] The optical fingerprint sensor structure 200 includes an optical fingerprint sensor 210 , a first adhesive layer 230 , a structural adhesive 250 , a photosensitive film 260 and a substrate 270 . see figure 2 , figure 2 A schematic structural diagram of the optical fingerprint sensor structure 200 provided by the present invention is shown.

[0037...

no. 2 example

[0052] This embodiment provides an optical fingerprint sensor structure 200. It should be noted that the basic principle of the optical fingerprint sensor structure 200 provided in this embodiment is basically the same as that of the optical fingerprint sensor structure 200 provided in the first embodiment. For a brief description, Please refer to the first embodiment for the parts not mentioned in this embodiment.

[0053] In the optical fingerprint sensor structure 200 provided in this embodiment, the thickness of the cover ink layer 261 is greater than 16 microns due to process requirements (such as printing LOGO or patterns), for example, it can be 20 microns; the thickness of the color ink layer 262 Thickness greater than 25 microns.

[0054] Both the cover ink layer 261 and the color ink layer 262 are added with a hardener, such as isocyanate, to increase the hardness of the cover ink layer 261 and the color ink layer 262, and prevent the excessive internal stress of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com