Valveless filter with lift breaking bucket

A valveless filter and destruction bucket technology, applied to loose filter material filters, gravity filters, filter separation, etc., can solve problems affecting normal work and achieve the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

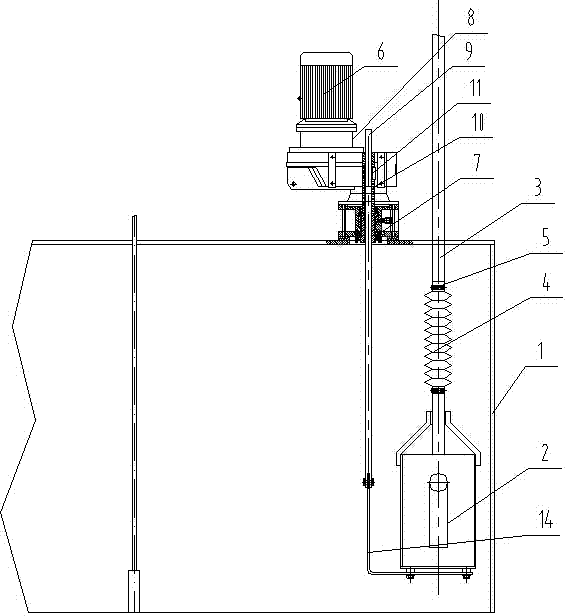

[0012] Such as figure 1 , 2 As shown, the filter tank 1 is included, the filter tank 2 is provided with a destruction bucket 2, the destruction bucket 2 is connected to the siphon destruction pipe 3 through the expansion joint 4, and the expansion joint 4 is respectively connected to the destruction bucket 2 and the siphon destruction pipe 3 through the hoop 5, and the filter A control machine mechanism 6 for controlling the lifting of the destruction bucket is installed on the tank 2 .

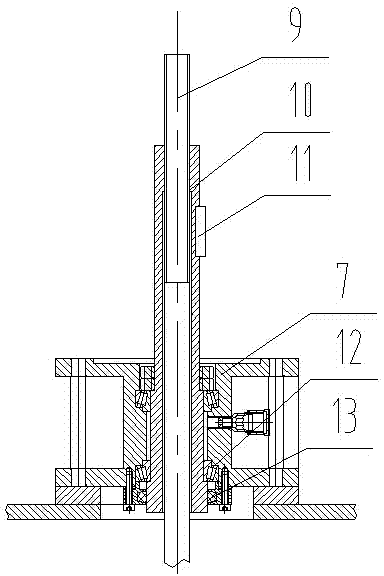

[0013] The control mechanism 6 includes a bearing seat 7, a reducer 8, a screw 9 and a nut 10. The bearing seat 7 is sealed and connected to the upper surface of the filter tank 1. The reducer 8 is installed on the bearing seat 7. The upper part of the nut 10 is connected by a key 11. At the output end of the reducer 8, the lower part of the nut 10 is connected with the bearing seat 7 through the bearing 12, and a sealing ring 13 is arranged between the lower end of the bearing seat 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com