Steering and shifting device of moving trolley

A mobile device and mobile trolley technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high gear processing and installation requirements, high oil cylinder configuration cost, inconvenient installation and maintenance, etc., and achieve transmission stability. High, low cost, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

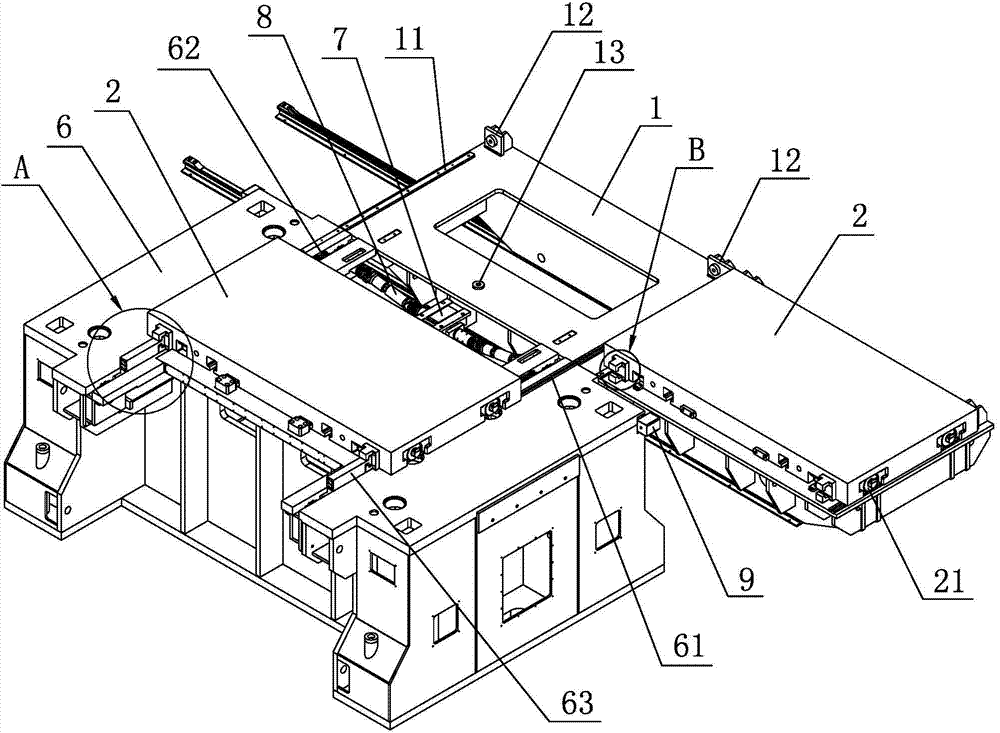

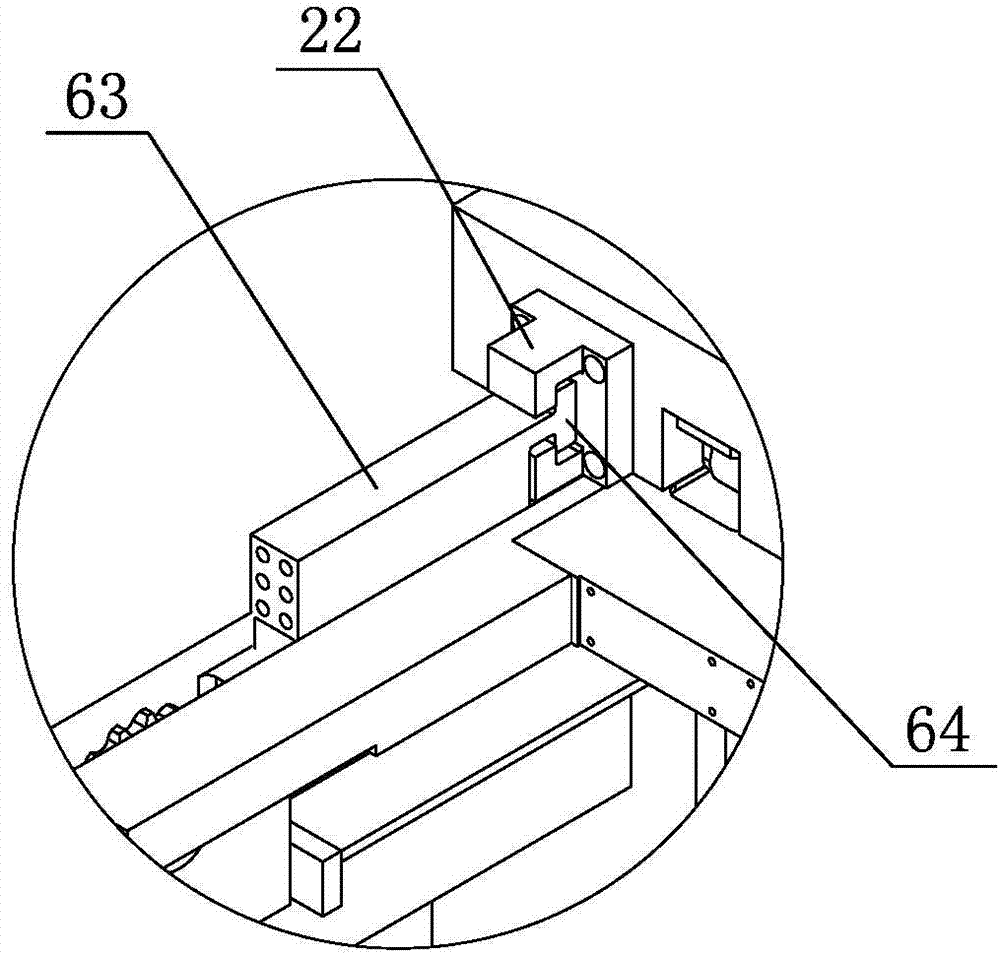

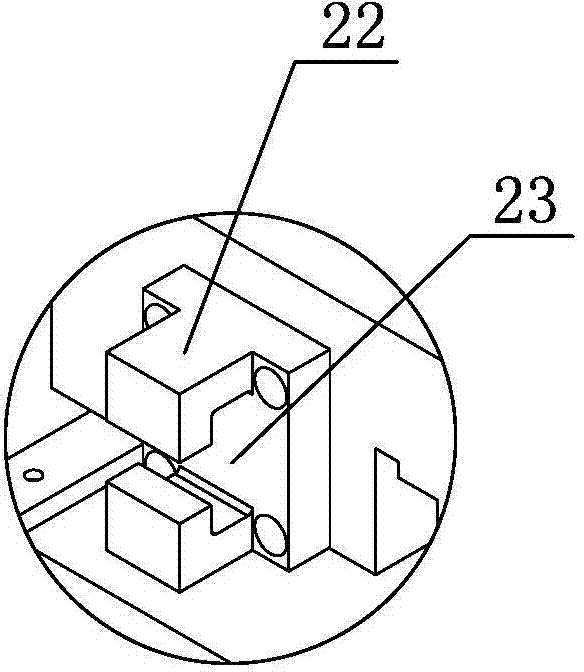

[0016] As shown in the figure, a steering and moving device for a mobile trolley includes a mobile trolley 1 that moves left and right along the foundation. Two worktables 2 are arranged side by side on the mobile trolley 1, and rollers 21 are provided on the lower end surface of the workbench 2. The upper end surface of the trolley 1 is fixedly provided with two sets of first rails 11 that match the rollers 21 side by side. The first guide rails 11 extend forward and backward and are perpendicular to the moving direction of the mobile trolley 1 . A positioning mechanism is arranged between them, and the positioning mechanism includes an in-position block 12 and a positioning pin 13. The in-position block 12 is fixedly arranged on the upper end surface of the mobile trolley 1 and is located on the rear side of the workbench 2, and the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com