Pneumatic double-jaw chuck for mini-tillers

A double-jaw chuck and micro-tiller technology, applied in the direction of the chuck, etc., can solve the problems of affecting the machining accuracy, unstable fixation, affecting the production efficiency, etc., and achieve the effect of convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

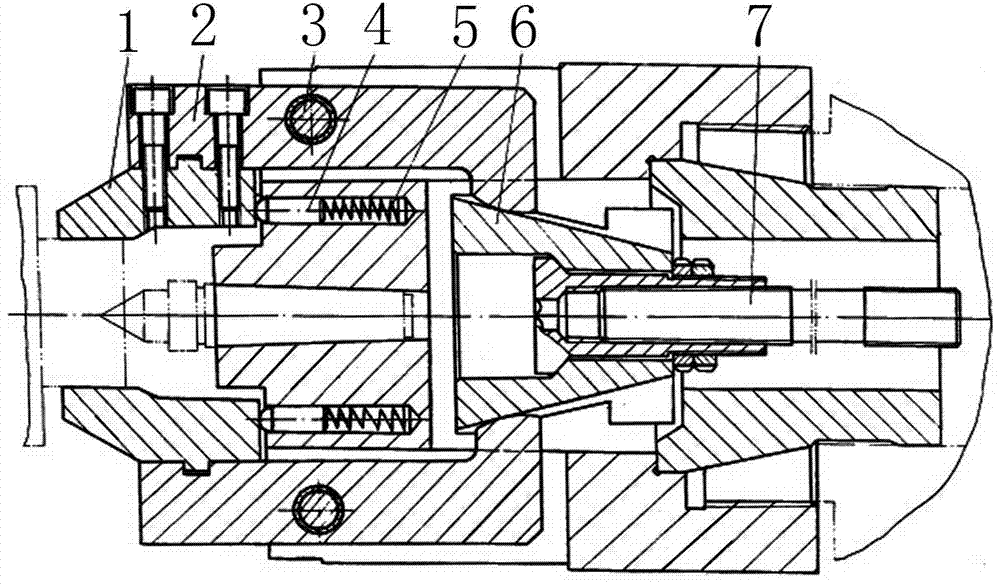

[0013] The reference signs in the drawings of the description include: claw 1, lever 2, pin shaft 3, ejector pin 4, spring 5, cone 6, pull rod 7.

[0014] The embodiment is basically as figure 1 Shown: The pneumatic double-jaw chuck for tillage machine includes a base, jaw 1, positioning block, lever 2, cone 6 and pull rod 7, the base is hollow, and its right end is detachably connected to the machine tool spindle , There are two penetrating strip grooves on the outer edge of the left end of the base. The left end of the tie rod is connected to the cone. The size of the cone gradually decreases from left to right. There is a stepped hole in the cone. It is clamped at the stepped hole, the right end of the connector protrudes from the cone and is connected with a nut, which is convenient for installation and disassembly. The pull rod is clamped through the connector to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com