Spherical object limiting jig

A kind of article and spherical technology, applied in the field of limit fixtures, can solve the problems of inconvenient limit, high production cost, damage, etc., and achieve the effect of increasing limit stability, reducing production cost, and saving space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

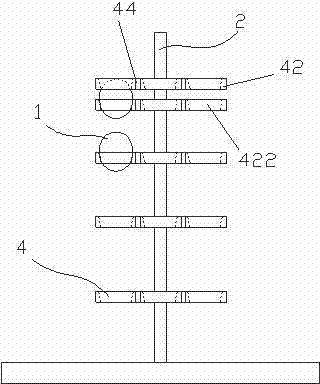

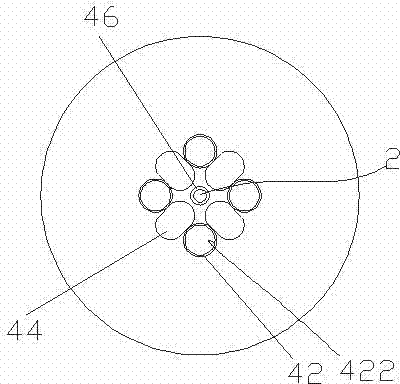

[0023] like Figure 1-2 As shown, a spherical article limit fixture includes a main support frame 2 extending in the height direction, and a five-layer auxiliary support frame 4 arranged on the main support frame 2. The auxiliary support frame 4 is provided with a The four accommodating holes 422 are distributed, and the upper opening diameter of the accommodating hole 422 is larger than the lower opening diameter, and the upper opening diameter is smaller than the maximum cross-sectional size of the spherical object 1 .

[0024] The auxiliary support frame 4 specifically includes four ring-shaped and evenly distributed snap rings 42, the inner circumference of the snap rings 42 forms accommodating holes 422, and a reinforcement connecting the two snap rings 42 is provided between adjacent two snap rings 42. Rib 44 is conducive to improving the overall strength.

[0025] The five-layer sub-support frames 4 are sleeved on the rod-shaped main support frame 2 through rubber ring...

Embodiment 2

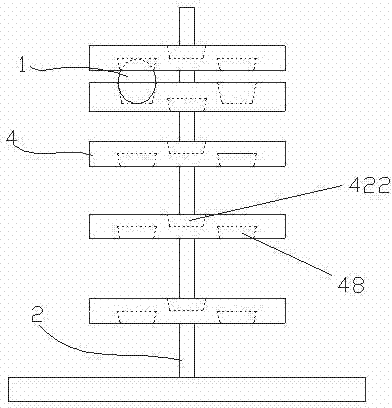

[0029] like Figure 3-4 As shown, a spherical object position limiting jig differs from Embodiment 1 in that the sub-support frames 4 of each layer are disc-shaped. An accommodating hole 422 is provided at the top of the auxiliary support frame 4 , and a groove 48 is provided at the bottom. The accommodating holes 422 and grooves 48 on each sub-support frame 4 are arranged at intervals along the circumferential direction. And the groove 48 of the uppermost sub-support frame 4 corresponds to the accommodating hole 422 of the adjacent lower sub-support frame 4 , so the spherical object 1 accommodated in the lower accommodating hole 422 can be clamped up and down.

[0030] When using the jig for limiting spherical objects in this embodiment, the spherical objects 1 can be placed in the accommodating holes 422 of any sub-support frame 4 to obtain the positioning. Further, the uppermost sub-support frame 4 can be pressed down, so that the corresponding upper layer groove 48 holds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com