Pallet with buffering cushion

A buffer pad and pallet technology, applied in the field of material transfer equipment, can solve problems such as inconvenient loading and unloading and storage, hidden dangers of cargo safety, and insufficient mechanical strength, and achieve the effects of low cost, improved safety, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

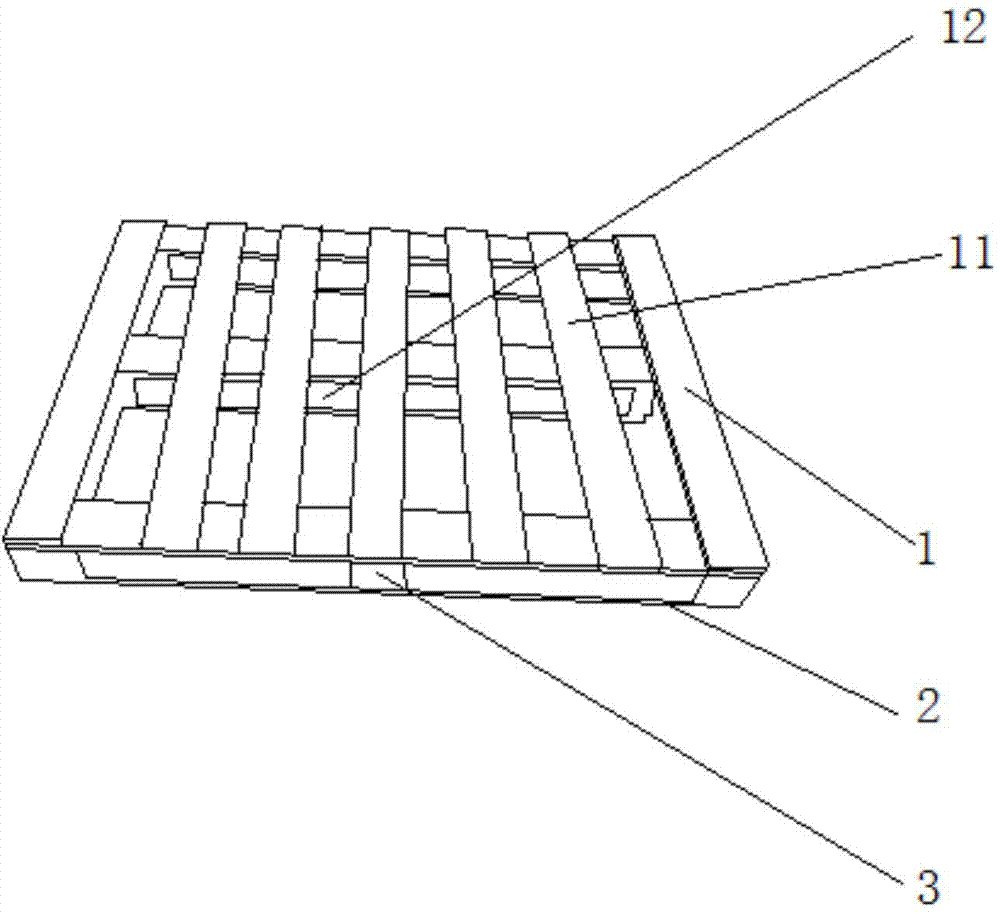

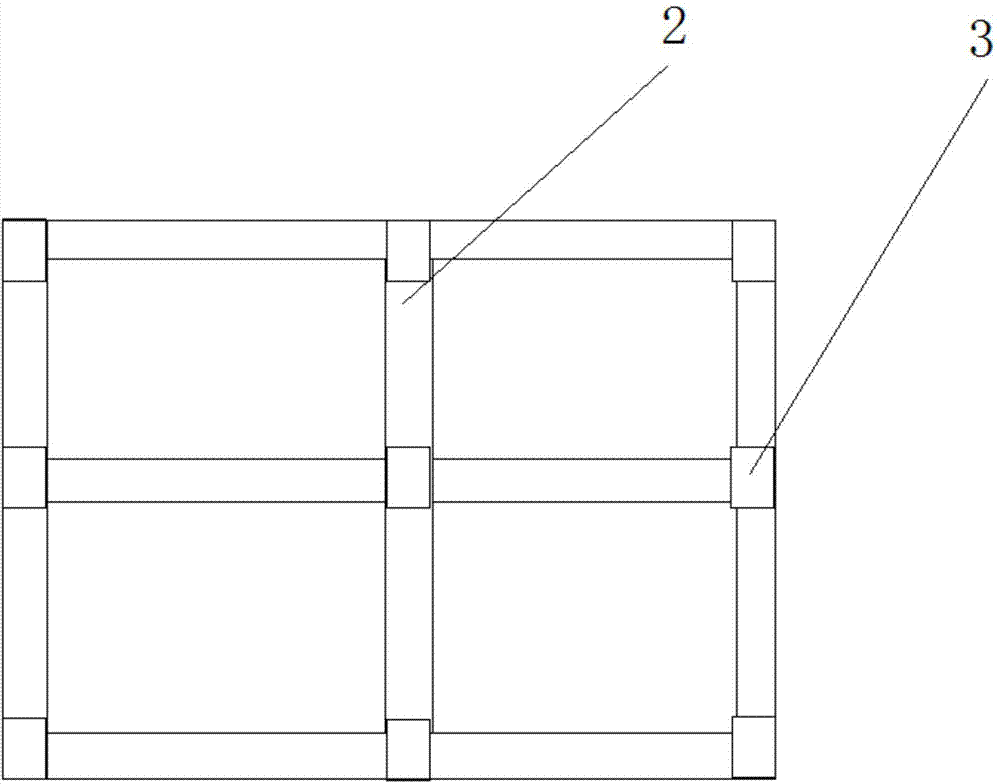

[0020] Such as figure 1 , figure 2 and image 3 Shown: a double-layer pallet rack, including a square material placement layer 1 and a ground contact layer 2, and a cushion block 3 arranged between the material placement layer 1 and the ground contact layer 2;

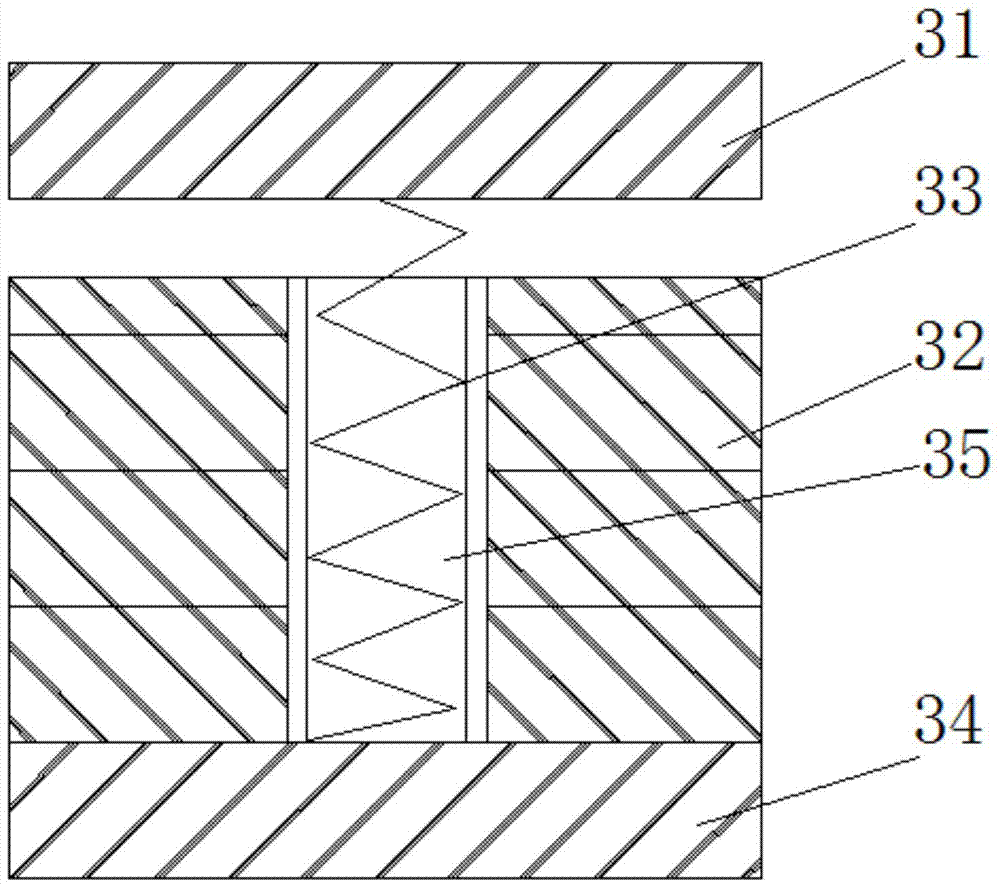

[0021] The buffer block 3 includes an upper connecting plate 31, a middle supporting plate group 32, a buffer spring 33 and a lower connecting plate 34. The supporting plate group 32 is composed of four rectangular rubber blocks that are parallel to each other and have the same structure. The center of the support plate group 32 has a through hole 35, the buffer spring 33 is inserted through the through hole 35, and the two ends of the buffer spring 33 are respectively connected to the upper connecting plate 31 and the lower connecting plate 34;

[0022] The material place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com