Automatic lifting platform applied to motor homes

An automatic lifting platform and automatic lifting technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of shrinkage height limitation, poor stability, low bearing capacity of pneumatic lifting mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

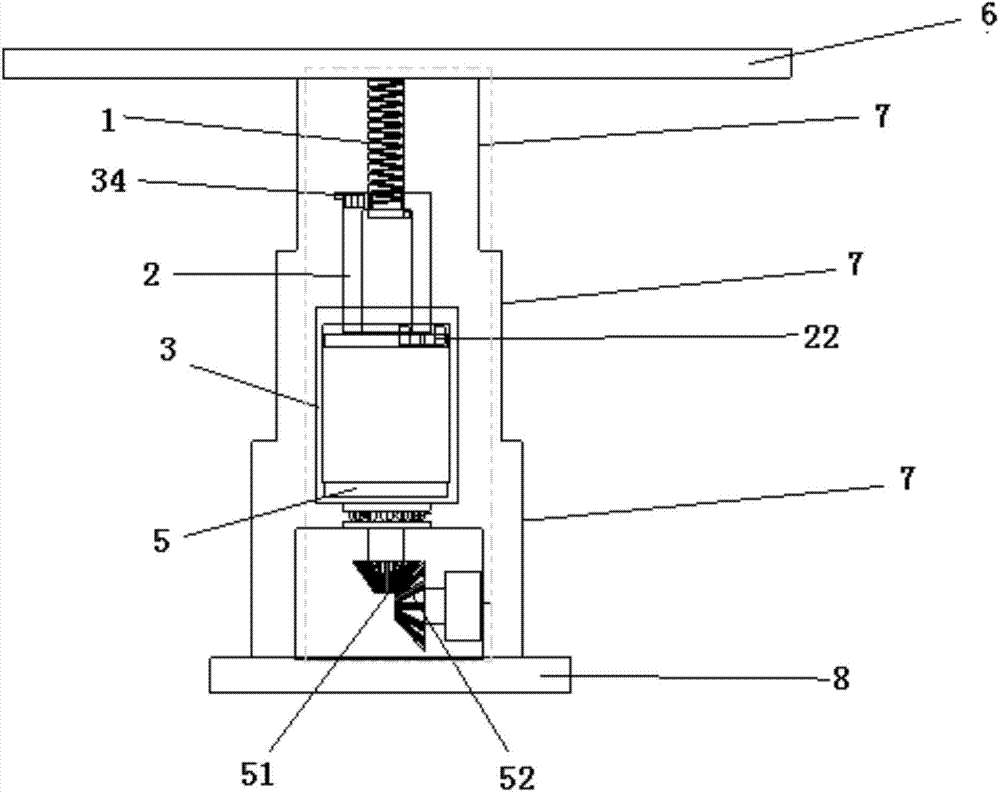

[0027] Example 1, such as Figure 1-4 Shown:

[0028] A self-elevating platform for a caravan, mainly comprising: a lead screw 1, an inner sleeve 2 wrapping the lead screw 1 and an outer sleeve 3 wrapping the inner sleeve 1, the top of the lead screw 1 is provided with a lifting platform support surface 6, the lifting platform The bottom platform 8 and the side of the lifting platform are provided with sleeves 7 .

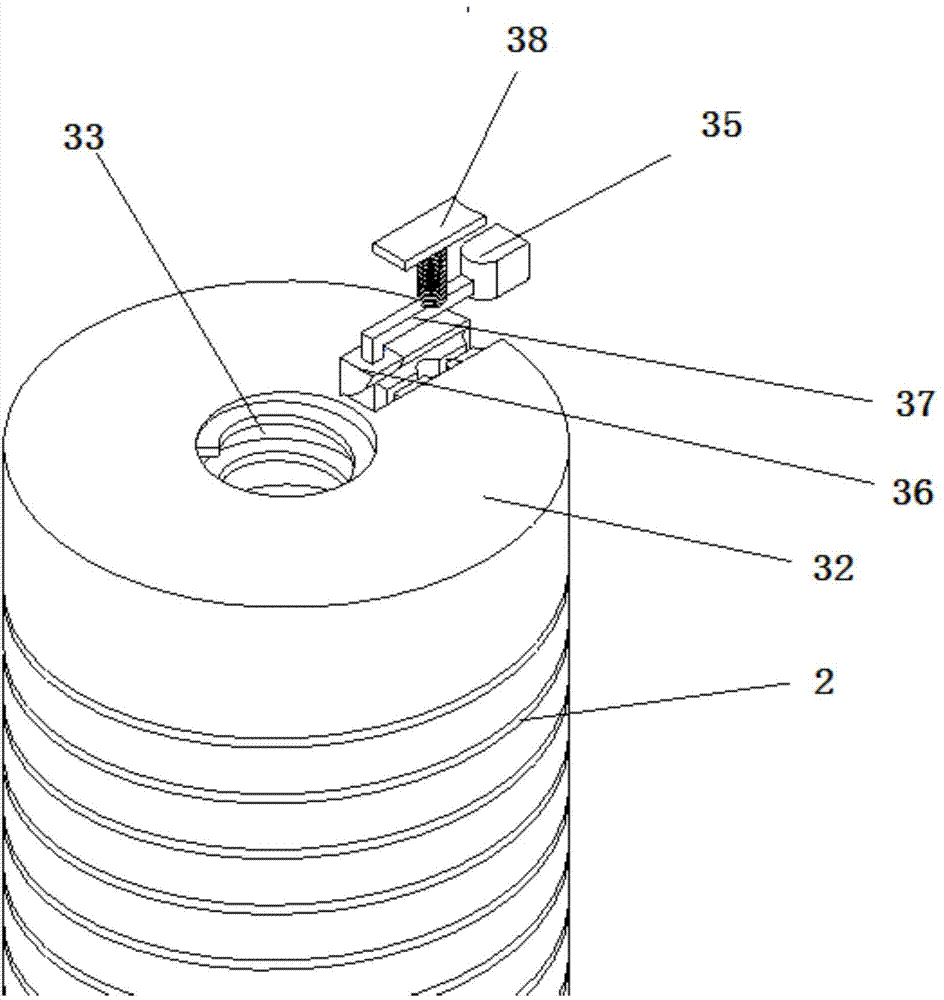

[0029] The top pipe of the outer casing 3 is a cover plate I31 which is integrally formed with the side wall of the outer casing 3 (it can also be detachably connected according to actual conditions), and the center of the cover plate I31 has a through hole I32 with an internal thread. The inner casing 2 is threadedly connected with the through hole I32.

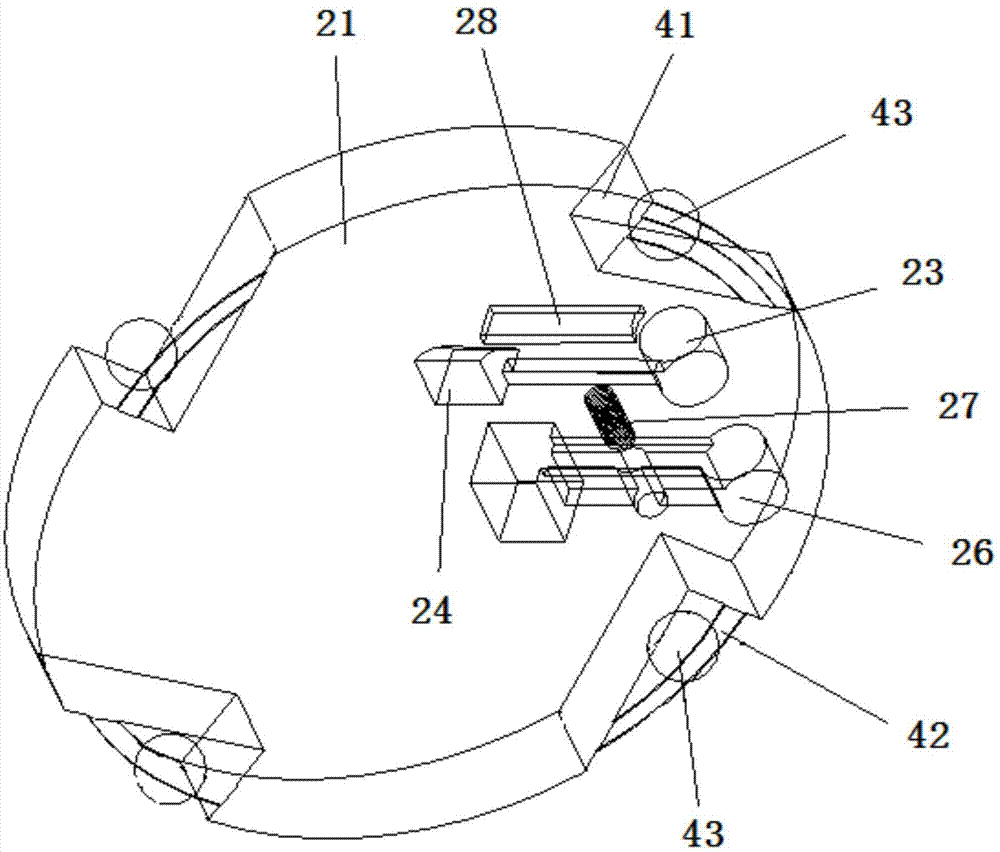

[0030] A baffle plate 21 is provided at the bottom of the inner sleeve 2 , and the outer diameter of the baffle plate 21 is larger than that of the inner sleeve 2 to ensure a certain space between the inner sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com