Umbrella reamer bit assembly

A reaming drill bit and umbrella-type technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of inability to carry out pile pressing work and difficulty in pile pressing, and achieve a large adjustment range of contraction angle, uniform force, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

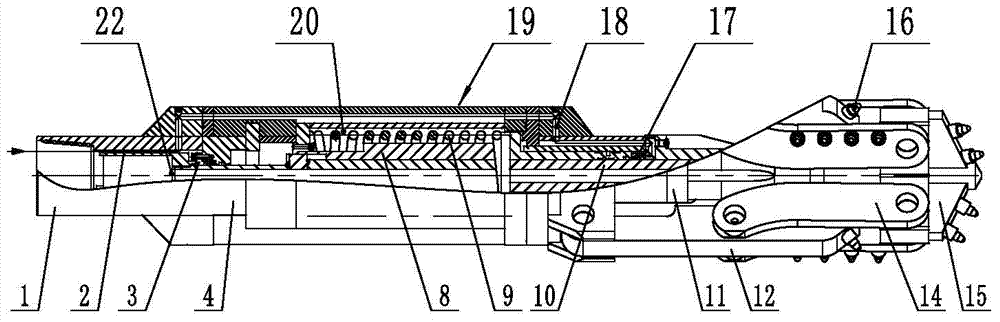

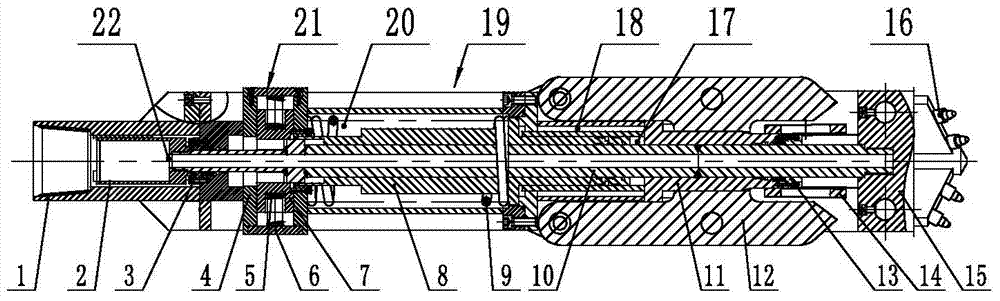

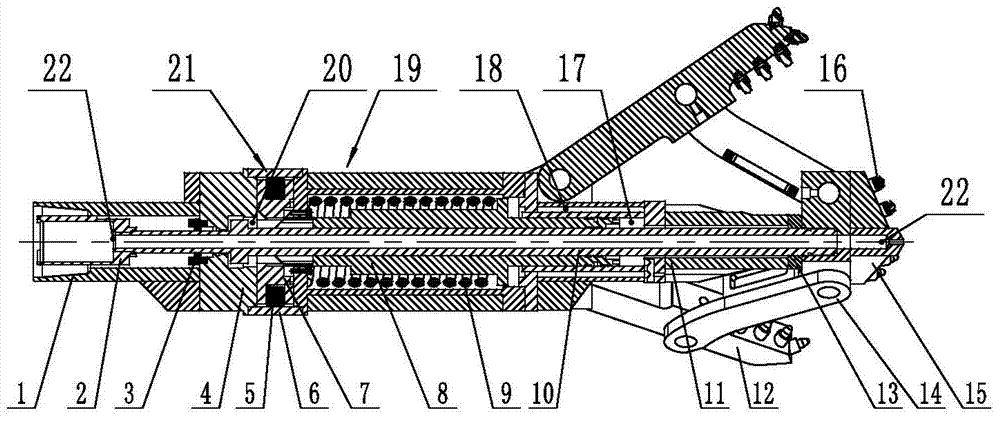

[0035] like Figure 1 ~ Figure 4 Shown, the present invention is a kind of umbrella type reaming drill bit, comprises water cylinder body 19 and drill bit 15.

[0036] The water cylinder body 19 has an inner closed space 20 . The water cylinder body 19 includes a rear shell 4 and a front shell 11 which are fixedly connected to each other. The rear end of the rear shell 4 is connected with an end cover 13 , and the front end of the front shell 11 is connected with a sealing cover 3 . A closed space 20 is enclosed by the end cover 13 , the rear casing 4 , the front casing 11 and the sealing cover 3 . The rear end of the rear shell 4 is connected with an external connector 1 .

[0037] A hollow mandrel 10 penetrating through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com