Two-stroke stratified scavenging engine

An engine and two-stroke technology, which is applied in the field of two-stroke layered scavenging engines, can solve problems such as unsatisfactory application prospects, installation space and cost constraints, and achieve the effects of sufficient scavenging, thorough ventilation, and reduced short-circuit losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

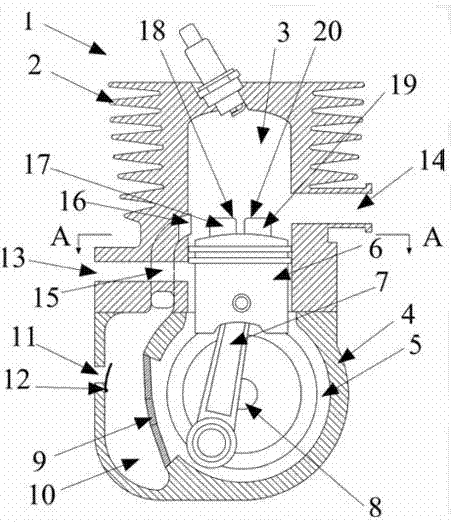

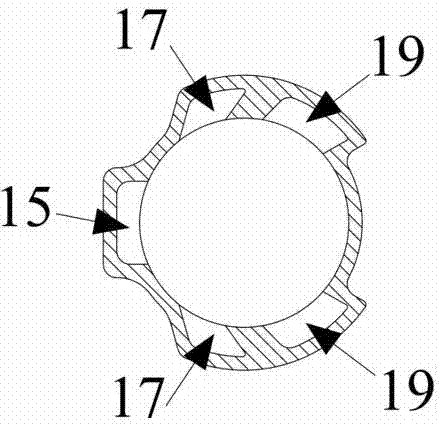

[0030] The invention as figure 1 , figure 2 As shown, a two-stroke stratified scavenging engine, the main technical solution

[0031] Yes, including: cylinder block 2, body 4, crankcase 5, piston 6, crankshaft 8, air scavenging components and mixed gas scavenging components, the air scavenging components are mainly composed of a diaphragm 9 fixedly connected to the body 4 It is composed of the air storage cavity 10 and the air scavenging channel 15 formed by the inner wall of the body 4, and the two ends of the air scavenging channel 15 are respectively connected with the air scavenging port 16 and the air storage cavity arranged on the inner wall of the cylinder body 2. 10 connected. The mixed gas scavenging component mainly includes mixed gas scavenging channels 17, 19, and the mixed gas scavenging channels 17, 19 are cavities jointly formed by the outer surface of the piston 6 and the grooves provided on the inner wall of the cylinder 2 The two ends of the mixed gas s...

Embodiment 2

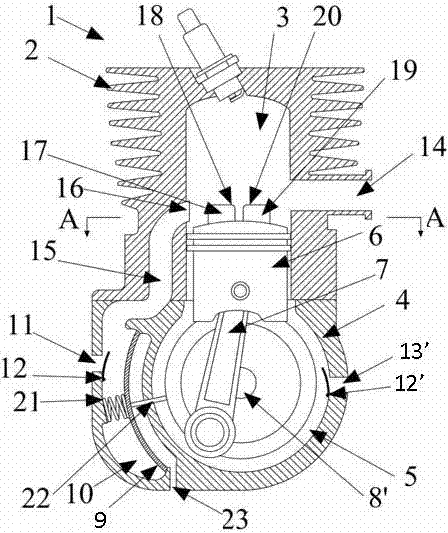

[0039] The invention as figure 1 , figure 2 , image 3 As shown, a two-stroke stratified scavenging engine, the main technical solution is to include: cylinder block 2, body 4, crankcase 5, piston 6, crankshaft 8', air scavenging components and mixed gas scavenging components, The air scavenging part is mainly composed of an air storage cavity 10 and an air scavenging channel 15 formed by the diaphragm 9 fixedly connected to the body 4 and the inner wall of the body 4, and the two ends of the air scavenging channel 15 are respectively connected to The air scavenging port 16 provided on the inner wall of one side of the cylinder body 2 communicates with the air storage cavity 10 . The mixed gas scavenging component mainly includes mixed gas scavenging channels 17, 19, and the mixed gas scavenging channels 17, 19 are cavities jointly formed by the outer surface of the piston 6 and the grooves provided on the inner wall of the cylinder 2 The two ends of the mixed gas scaven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com