A pipeline water energy recovery device

A recovery device and water energy technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low recovery efficiency, excessive energy, loss, etc., achieve efficient recovery, reduce pipeline pressure, and improve energy recovery efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

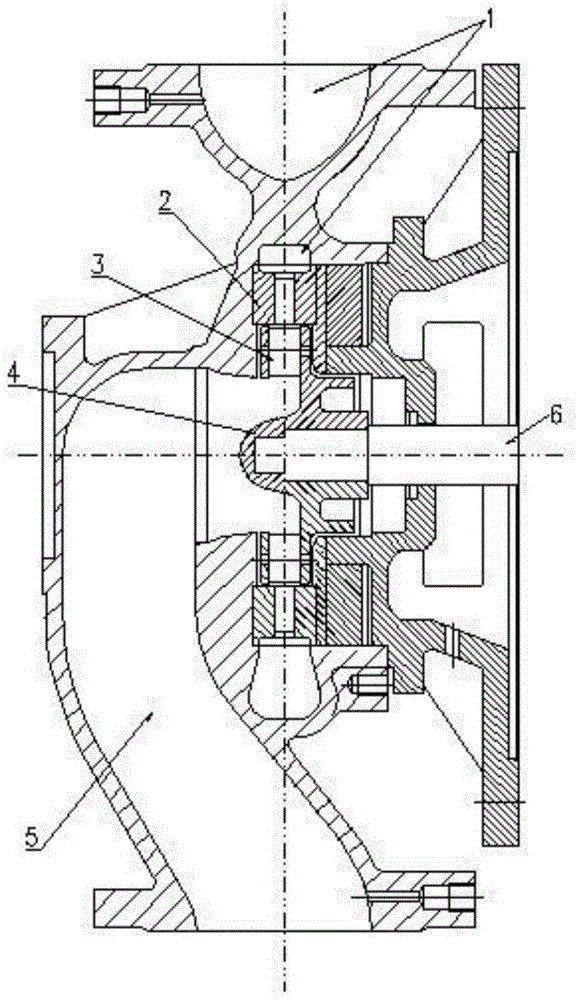

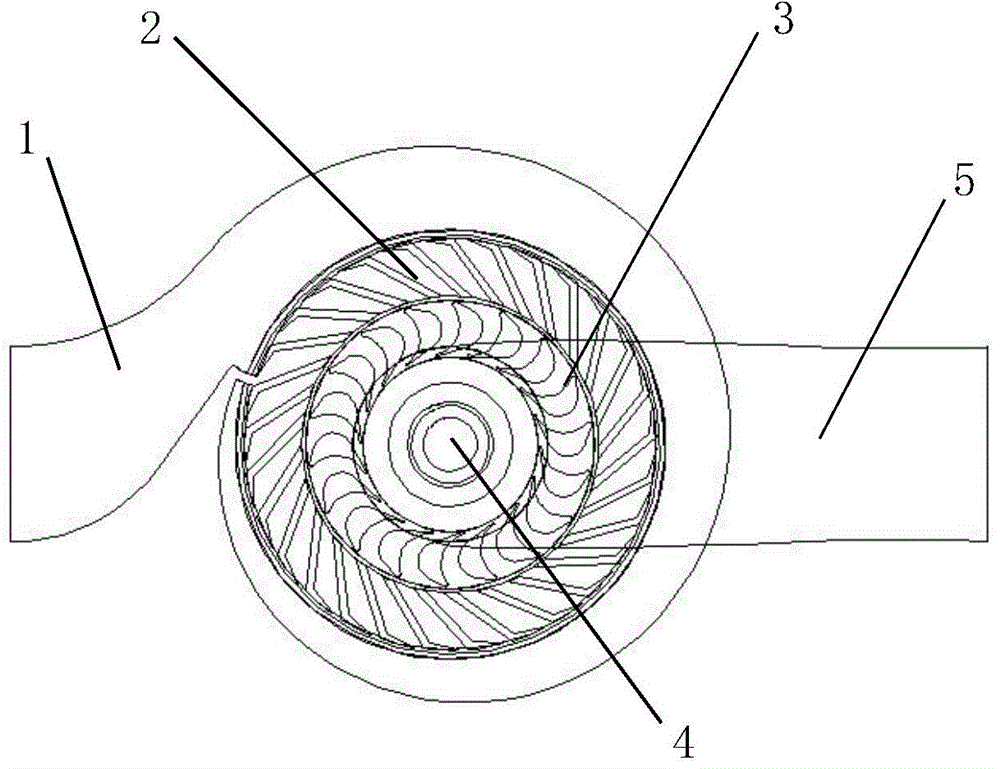

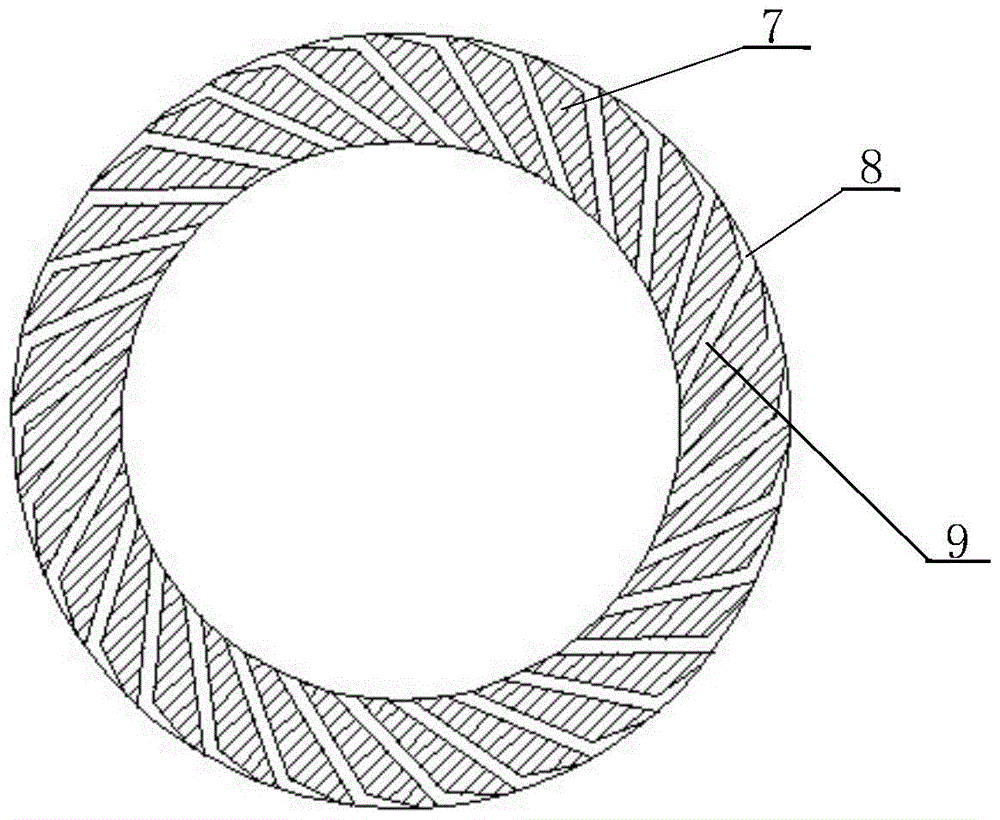

[0024] see Figure 1 to Figure 11 , the present invention includes a volute chamber 1 and a drainage chamber 2, the drainage chamber 2 is fixed on the volute of the volute chamber 1 by bolts, a rotating shaft 6 is installed on the casing, one end of the rotating shaft 6 is connected to the runner 3, and the other end drives the generator In the drainage chamber 2, several drainage cavities 7 are evenly distributed along the circumferential direction. The drainage cavity is the flow channel through which the fluid flows. The flow channel is divided into a front section flow channel 8 and a rear section flow channel 9. It communicates with the volute chamber 1, and the area of the rear flow channel 9 is constant, and communicates with the runner; the water outlet of the runner 3 is connected with the drain pipe 5. The drain pipe 5 and the volute chamber 1 can be integrally cast together, or can be separately cast and connected by bolts.

[0025] During use, the volute chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com