Sulfur friction test device

A test device, sulfur technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem of ignition mechanism without sulfur friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

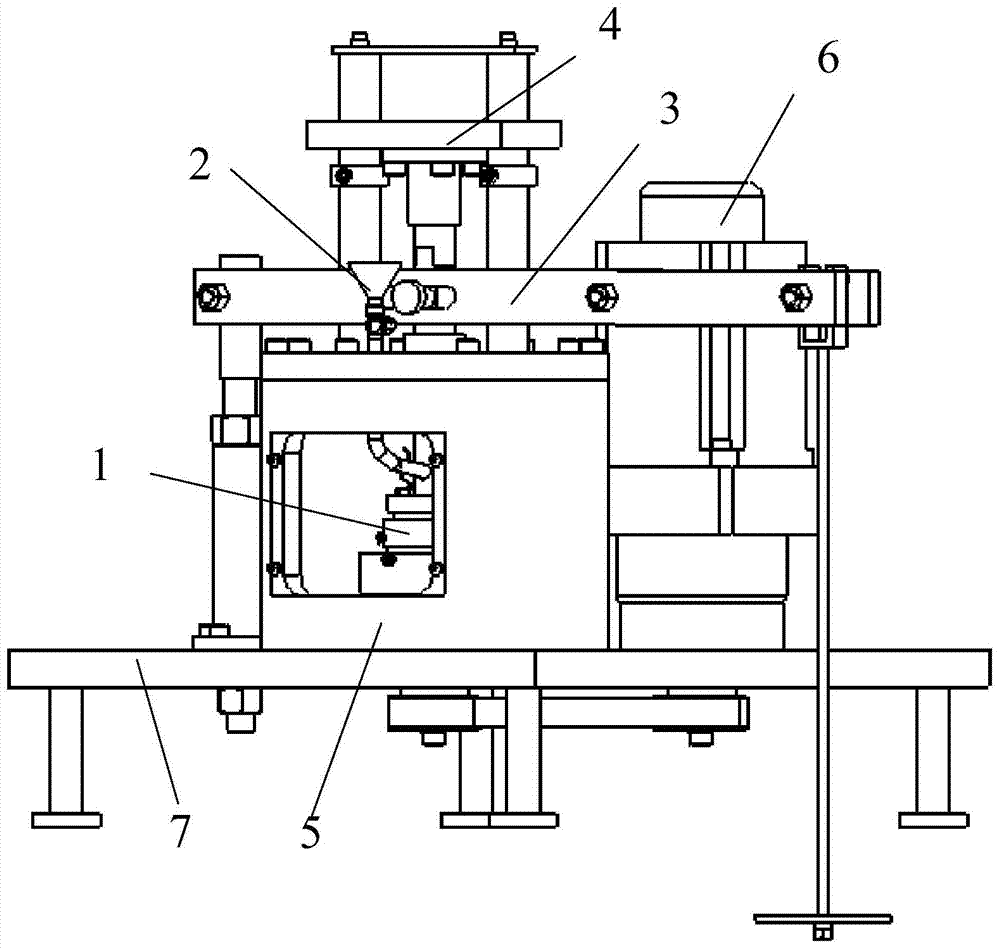

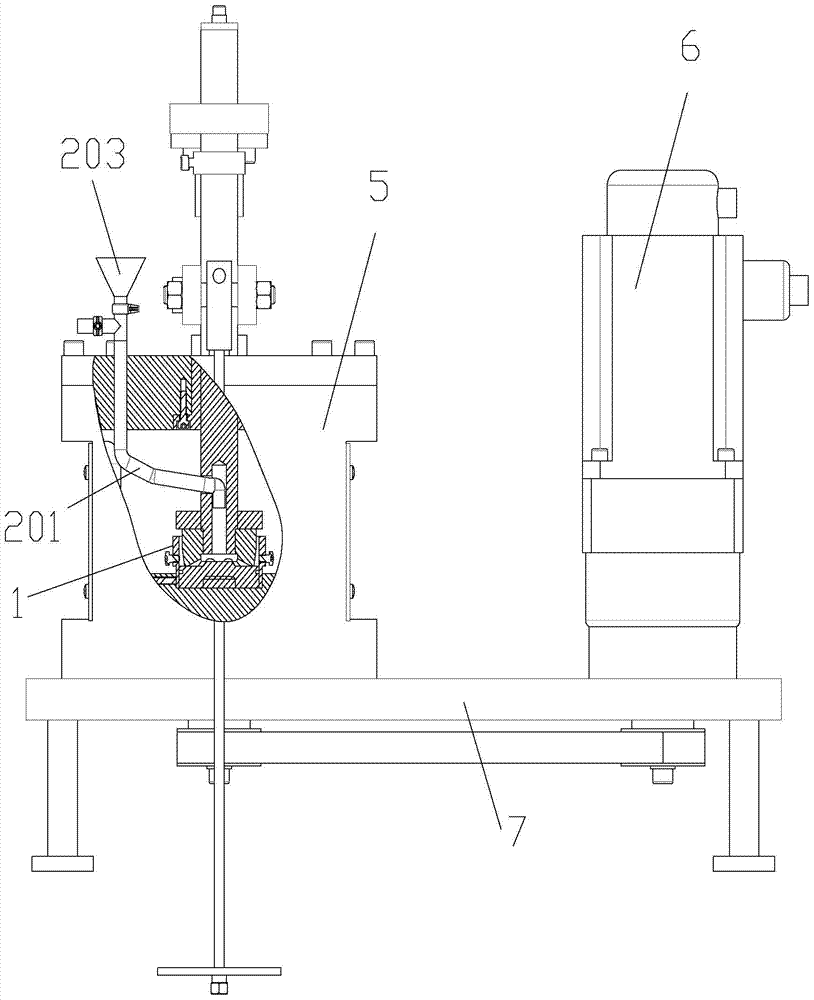

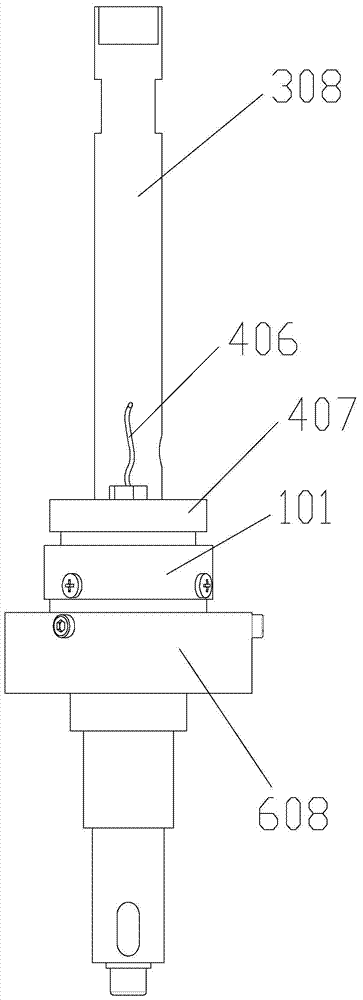

[0058] Such as figure 1 and Figure 14 As shown, the sulfur friction test device includes: a friction mechanism 1, a feeding mechanism 2, a loading mechanism 3, a sealing structure 5, a detection system 4, a transmission mechanism 6 and a base 7; the transmission mechanism 6, the sealing structure 5 and the loading mechanism 3 are all located on the base 7;

[0059] Such as Figure 12 As shown, the sealing structure 5 includes: a sealing cavity and a sealing cover 502 surrounding the sealing cavity; the sealing structure is designed in a cylindrical shape, and the inside is a hollow cylindrical shape, fixed on the base 701 . The sealing cover 502 is ring-shaped, and its upper and lower ends respectively cover the upper end cover 501 and the lower end cover 503 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com