Reciprocating type piston ring-cylinder sleeve friction wear testing machine

A friction and wear test, piston ring technology, applied in the direction of internal combustion engine testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as high price, lack of piston-cylinder liner friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

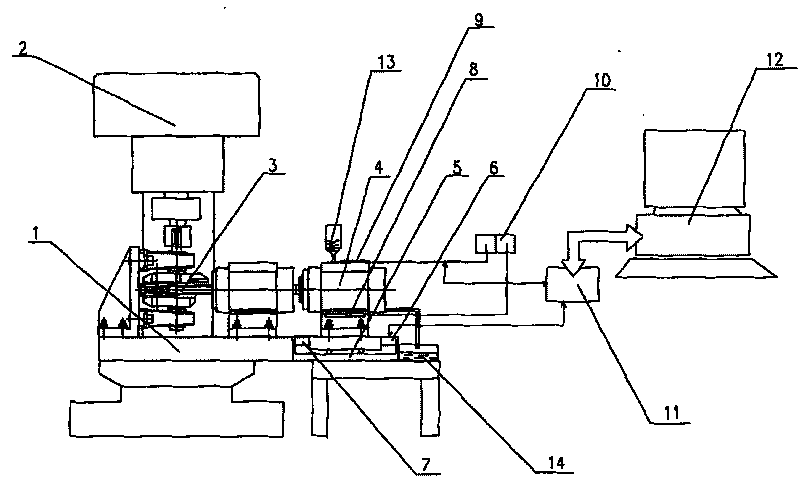

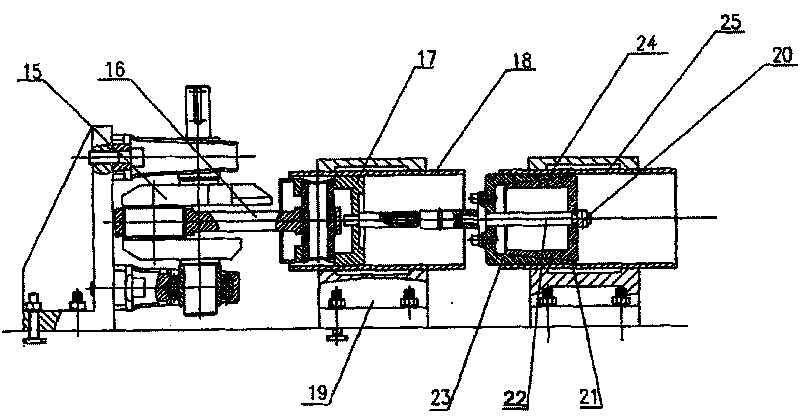

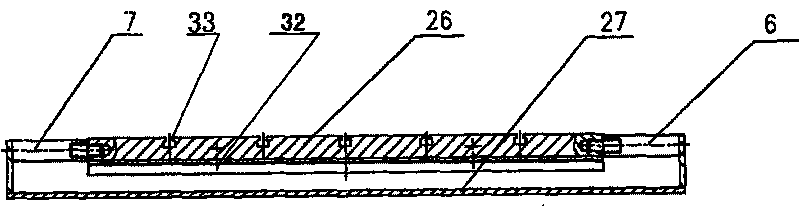

[0020] Referring to each figure, the testing machine is mainly composed of a crank linkage mechanism 3, a guiding mechanism, a loading mechanism 4, a lubrication device, a friction measuring device 5, a temperature measurement and control device 10, and a data acquisition and monitoring device.

[0021] The power device 2 uses the motor as the power source, which can be transformed from a small vertical drilling and milling machine. The main shaft part of the vertical drilling and milling machine is used as the power device of the experimental machine, which can provide a power of 1.1KW and a speed range of 9 levels Adjustable, nine-level adjustable power from 210 to 2550r / min. The motor shaft drives the crank-link mechanism 3, and then transforms into a linear reciprocating motion through the guide slider 17 and the guide sleeve 18 of the guide mechanism. The loading mechanism 4 adopts the structure of extruding the expansion sleeve to change the piston ring 24 on the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com