Loading device for corrosion test of steel-concrete bonded specimens under stress

A technology of loading device and stress action, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of stress corrosion, low stiffness, and unintuitive force applied to specimens that cannot be bonded to reinforced concrete. The force reading is intuitive and convenient, and the force application accuracy is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

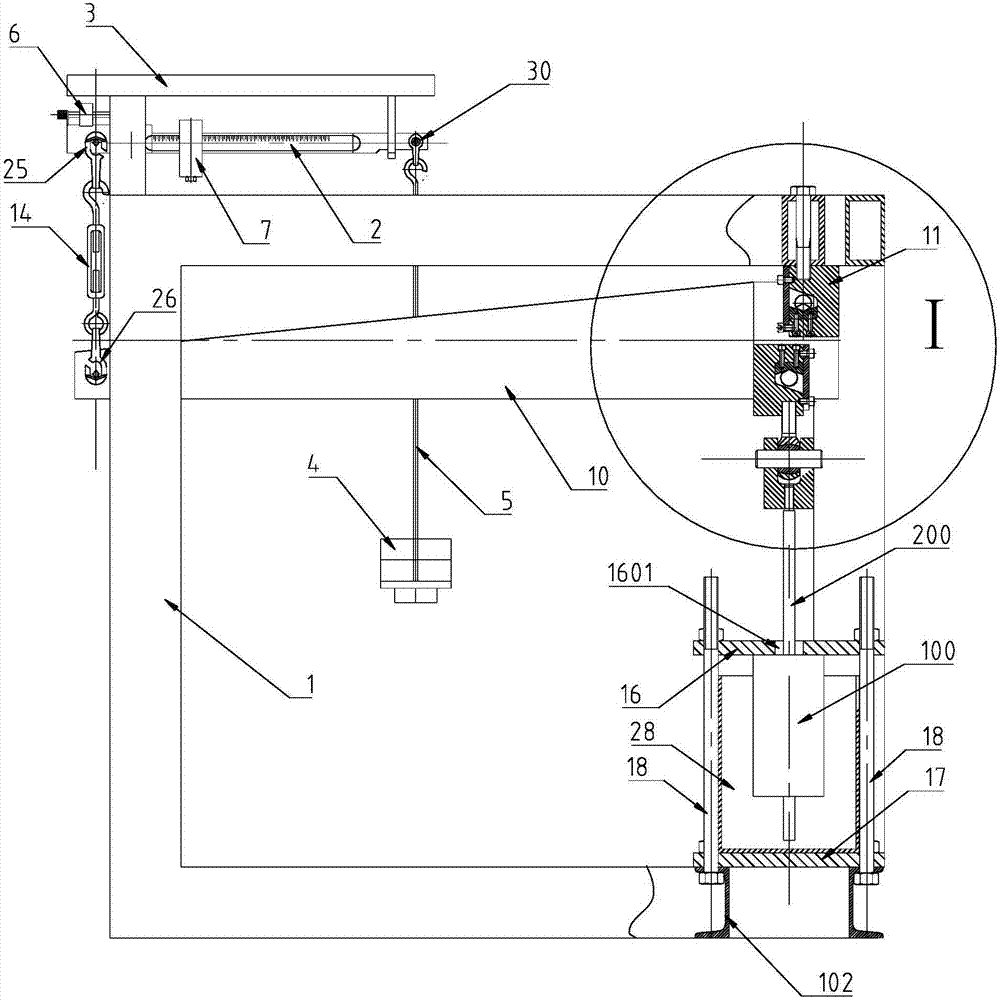

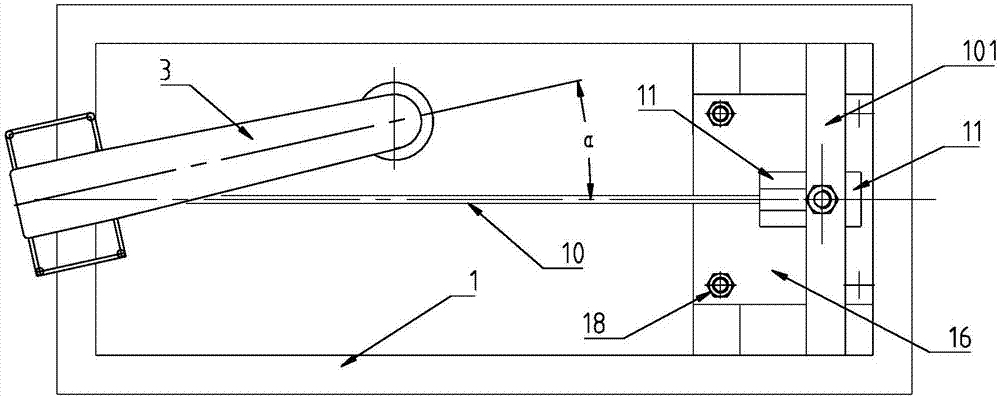

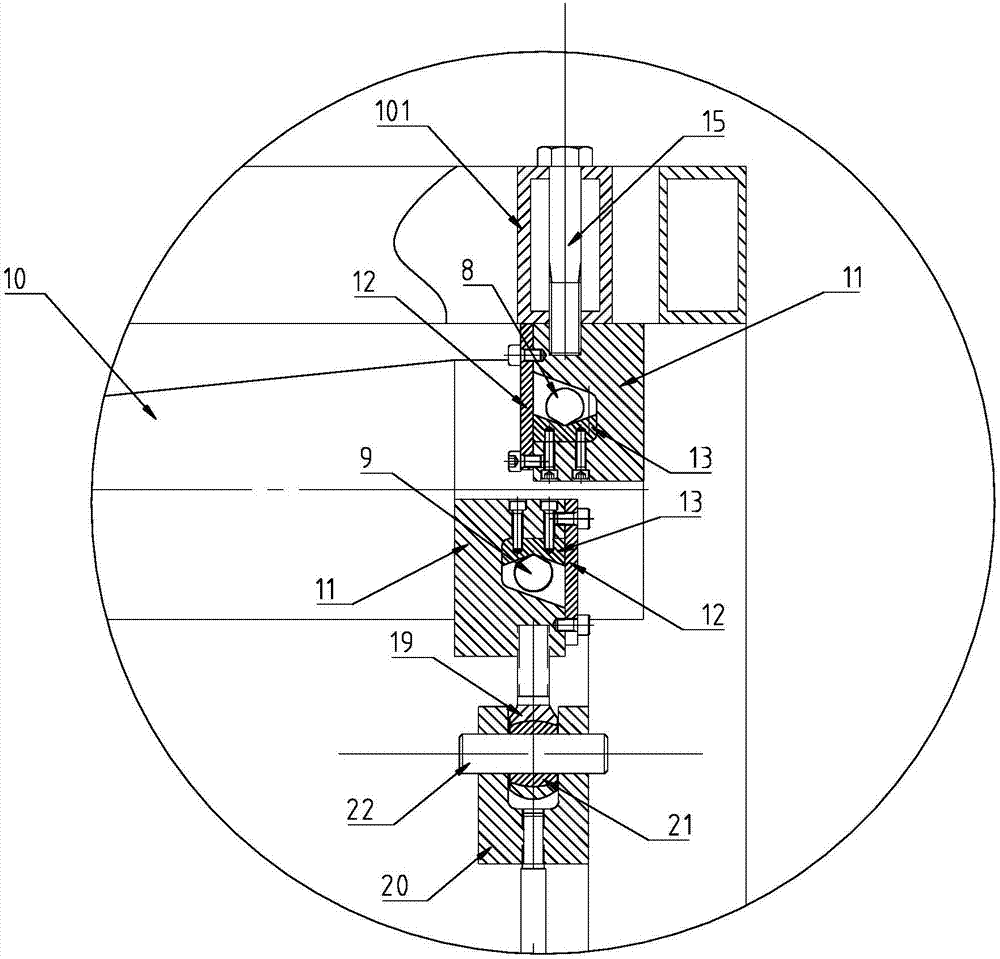

[0032] The structure of the embodiment of the loading device for the corrosion test of the steel bar-concrete bond sample of the present invention is as follows: Figure 1 to Figure 11 As shown, it includes a frame 1, a weighing lever mechanism with a metering lever 2 as the main body, a force lever 10, a connecting rod and a sample holder.

[0033] The metering lever 2 and the forcing lever 10 are staggered from each other. On the top-view projection plane, the included angle α between the metering lever 2 and the forcing lever 10 is 13°.

[0034] The weighing lever mechanism also includes a weighing frame 3 , an increasing weight 4 , a weight hanging 5 , a counterweight 6 and a traveling weight 7 . The scale frame 3 is fixed on the upper part of the frame 1, the measuring lever 2 is hinged with the scale frame 3 through the measuring lever fulcrum knife bearing group (the measuring lever fulcrum knife bearing group is not shown), and the weight hanging 5 is suspended on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com