Current-induced-heat-type defect evaluation method used for power equipment connecting part

It is a technology of current heating type and connecting components, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., to achieve the effect of improving reliability index and usability index of equipment, easy to use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

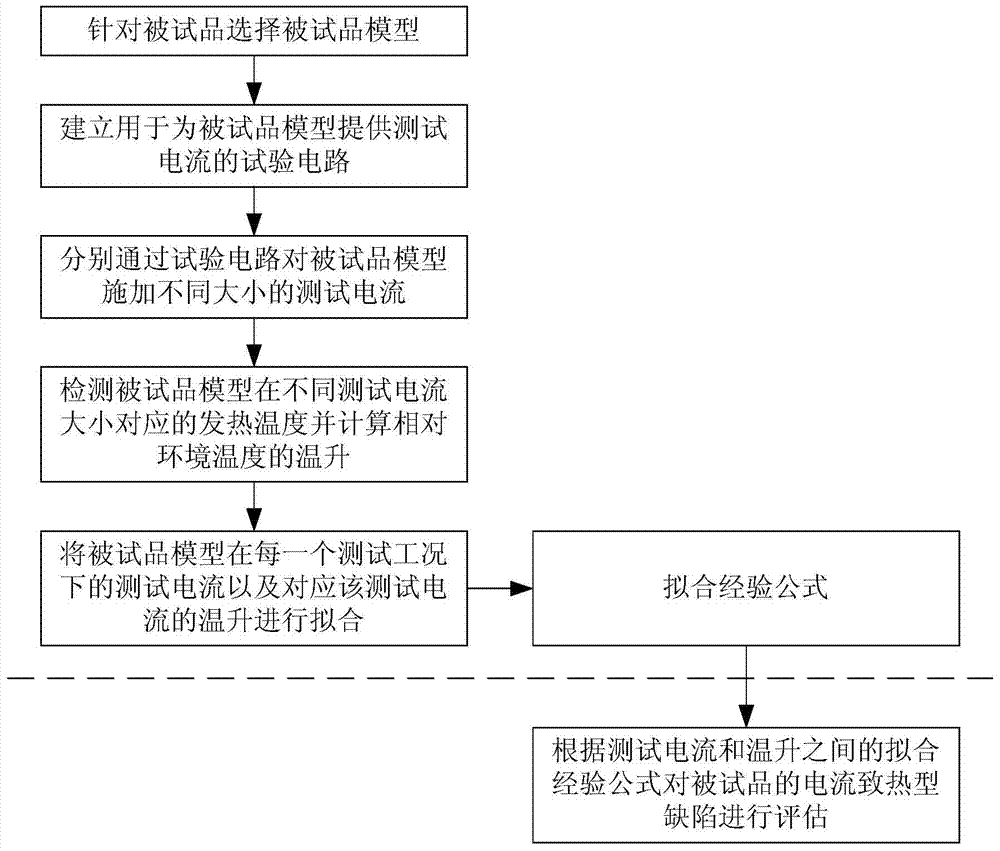

[0032] Such as figure 1 As shown, the steps of the current-induced heating-type defect evaluation method for the connecting parts of electric equipment in this embodiment include:

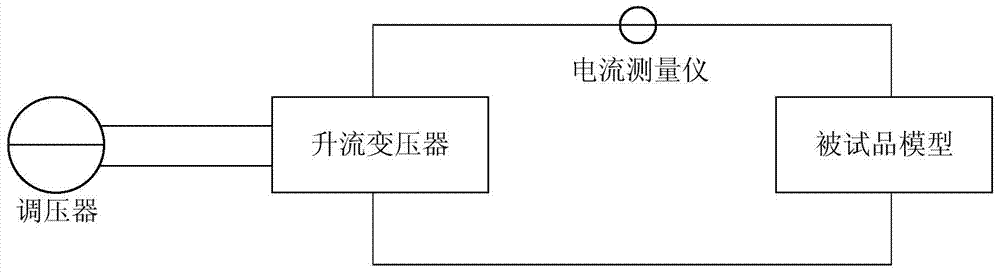

[0033] 1) Select the model of the tested product for the tested product, and establish a test circuit for providing the test current for the model of the tested product;

[0034] 2) Apply test currents of different sizes to the model of the tested product through the test circuit, detect the heating temperature of the heating point of the model of the tested product corresponding to different test currents, and calculate the temperature rise relative to the ambient temperature, and obtain the temperature of the tested product model in The test current under each test condition and the temperature rise corresponding to the test current;

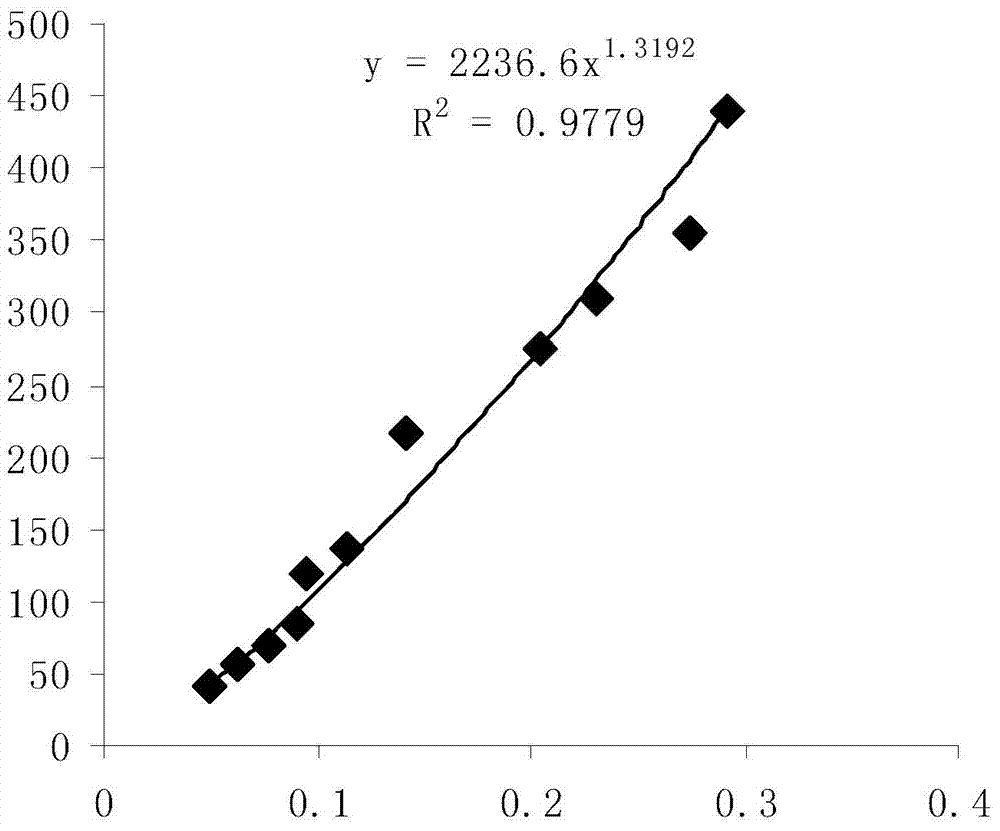

[0035] 3) Fit the test current of the model of the tested product under each test condition and the temperature rise corresponding to the test current to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com