High-online-rate open-type cement kiln intelligent optimization expert system

An expert system and intelligent optimization technology, applied in the general control system, control/regulation system, furnace control device, etc., can solve problems such as insufficient online rate, high coal and electricity consumption, complicated operation process, etc., and achieve fluctuation deviation reduction The effect of small size, reduced probability of skin clogging, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

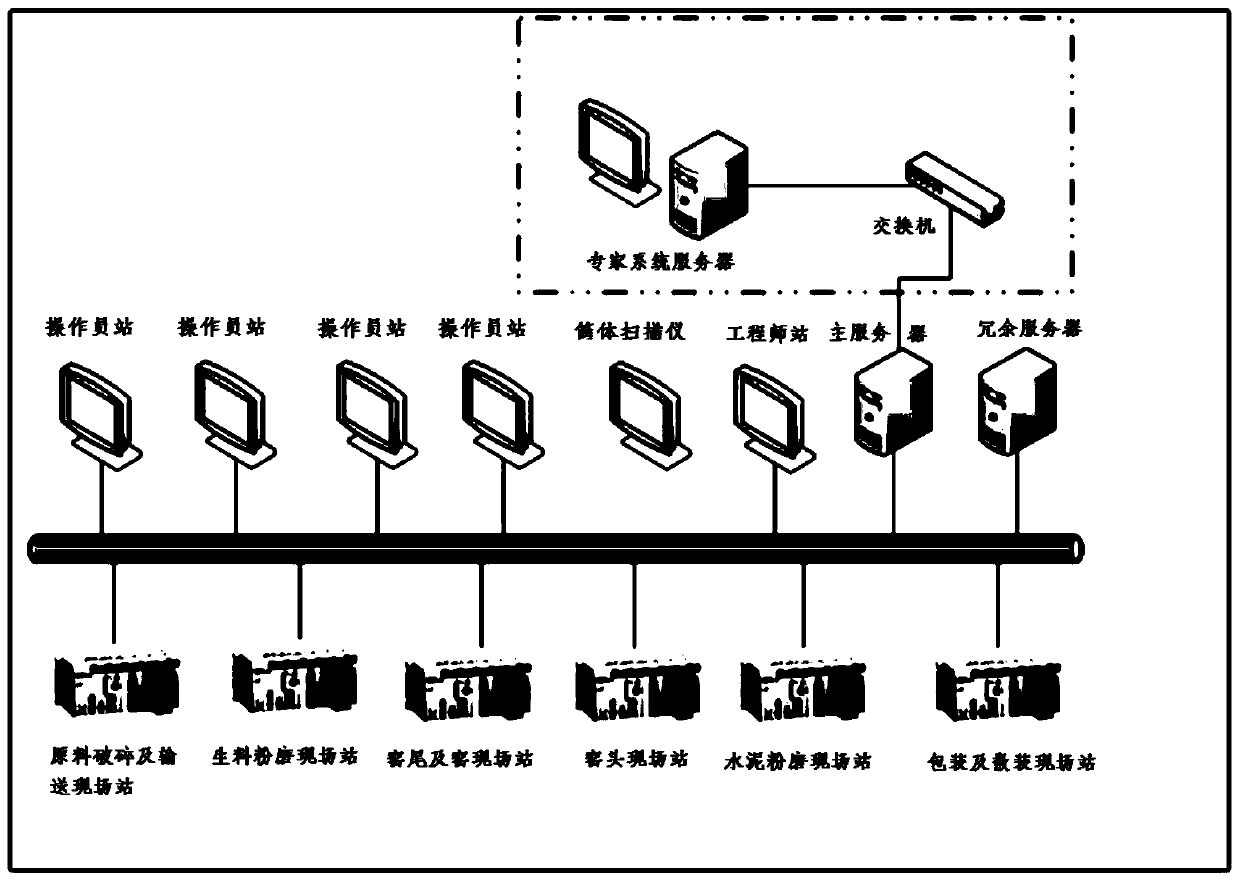

[0019] An open cement kiln intelligent optimization expert system with high online rate, referring to figure 1 , including the expert control system server ( figure 1 The expert system server in), the switch and the DCS control system, the DCS control system is equipped with a dedicated DCS function module and a proprietary control data access method, the expert control system server is connected to the data server in the DCS control system through a two-way communication through the switch, There is a bias device connected between the expert control system server and the DCS control system. The expert system control data is connected to the control mode with bias Bias, while maintaining the operator interface input. On the premise of following the operating habits, the expert system not only realizes the The two-way intelligent control of the cement kiln, more importantly, completely guarantees the safety of the production system. In addition, in view of this design concept,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com