a camera lens

A lens and image square technology, applied in the field of imaging lens, can solve the problems that the optical performance cannot be effectively improved, the miniaturization cannot be effectively achieved, and the imaging lens is not perfect, so as to meet the requirements of large aperture, high relative brightness and low production process and the effect of cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

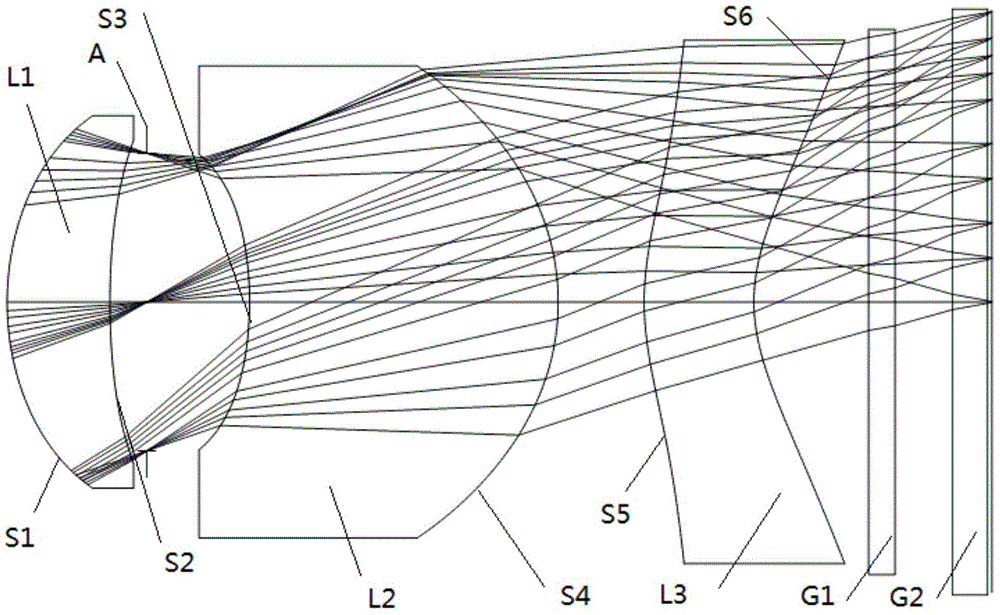

[0037] like figure 1 As shown, this embodiment provides an imaging lens, which includes three plastic lenses, and the surfaces of each lens are aspherical, and sequentially includes a first positive lens L1, a second positive lens L2 and a third negative lens L1 along the incident direction of light. Lens L3, wherein: the first positive lens L1 has positive refractive power, the second positive lens L2L2 has positive refractive power, and the third negative lens L3 has negative refractive power; specifically, the first positive lens L1 has a The first surface S1 and the second surface S2 concave toward the image side, the second positive lens L2 has a third surface S3 concave toward the object side and a fourth surface S4 convex toward the image side, and the third negative lens L3 has a convex toward the object side The fifth surface S5 of the square has the sixth surface S6 concave to the image side; the focal power of the entire group of lenses is taken as positive, the foc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com