An embedded touch screen and display device

A built-in touch screen, touch technology, applied in optics, instruments, electrical digital data processing and other directions, can solve the problem of uneven display screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementations of the in-cell touch screen and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

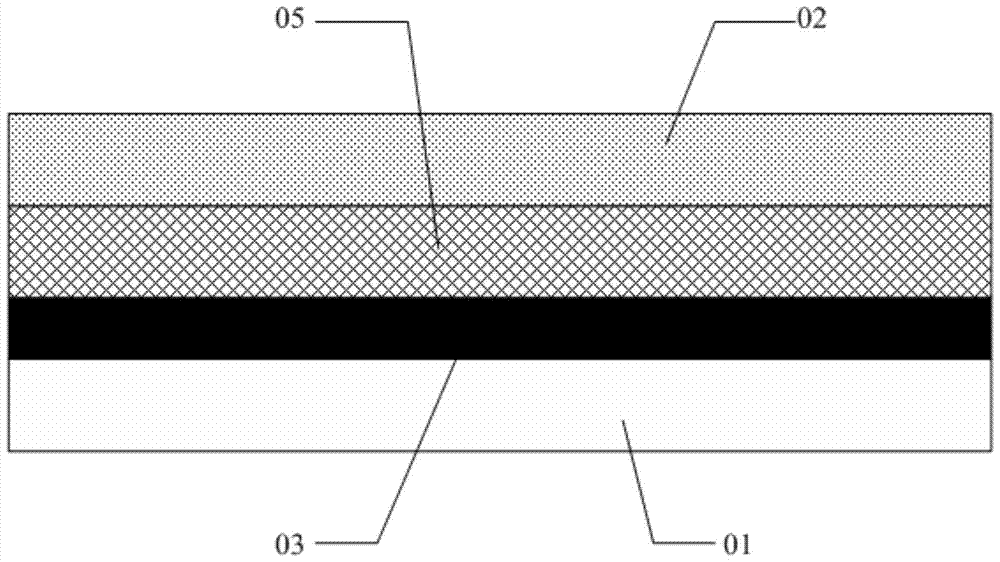

[0040] The thickness and shape of each film layer in the drawings do not reflect the true ratio, and the purpose is only to illustrate the content of the present invention schematically.

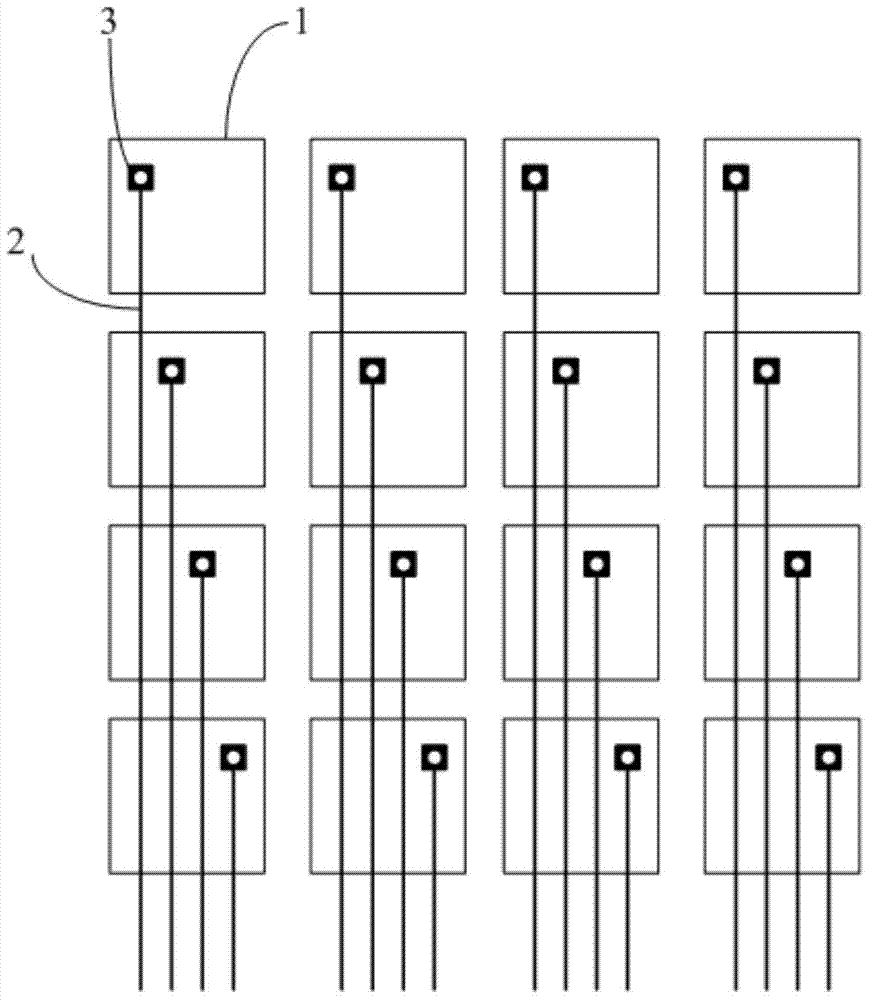

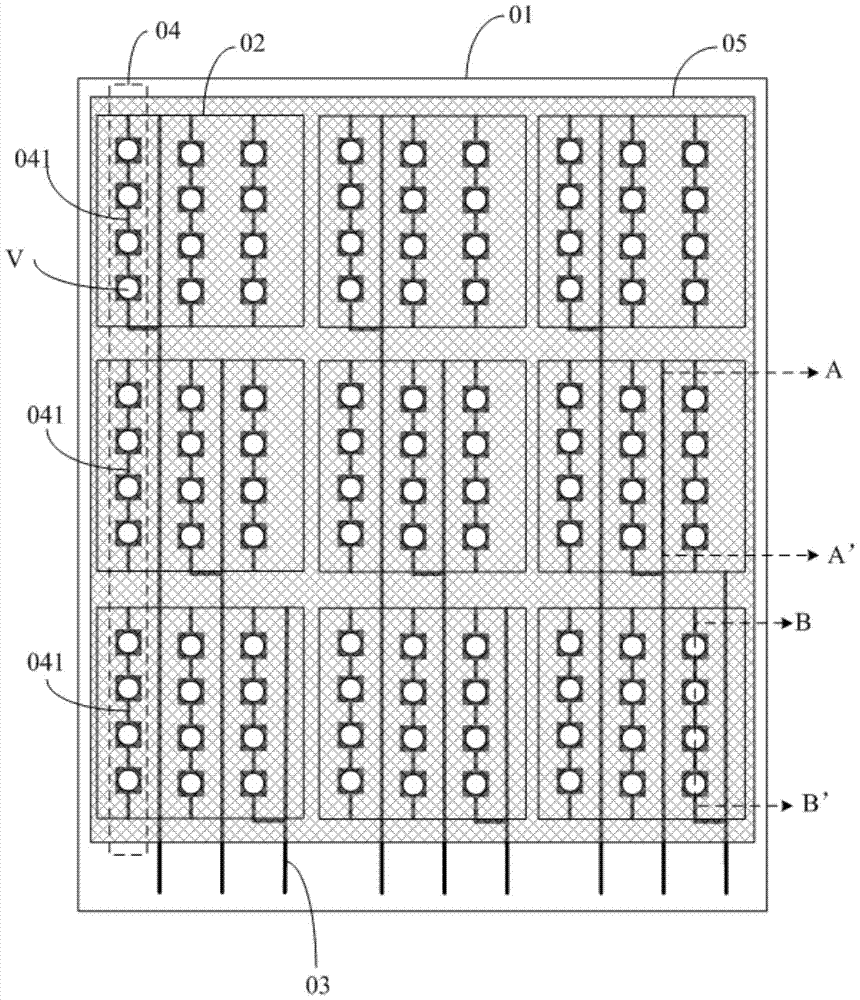

[0041] The embodiment of the present invention provides an in-cell touch screen, such as Figure 2a to Figure 2c As shown, the upper substrate (not shown in the figure) and the lower substrate 01 arranged oppositely have a plurality of independent self-capacitance electrodes 02 arranged in a matrix. During the touch time period, the capacitance value of each capacitor electrode 02 is detected to change to A touch detection chip (not shown in the figure) for determining the touch position, and a plurality of wires 03 arranged in a different layer from the self-capacitance electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com