a transcritical co 2 Evaluating Method of Efficiency of Ejector Diffuser Chamber in Refrigeration Cycle

A technology of refrigeration cycle and evaluation method, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as unreliability, turbulent mixing process of ejector, friction loss congestion, and difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

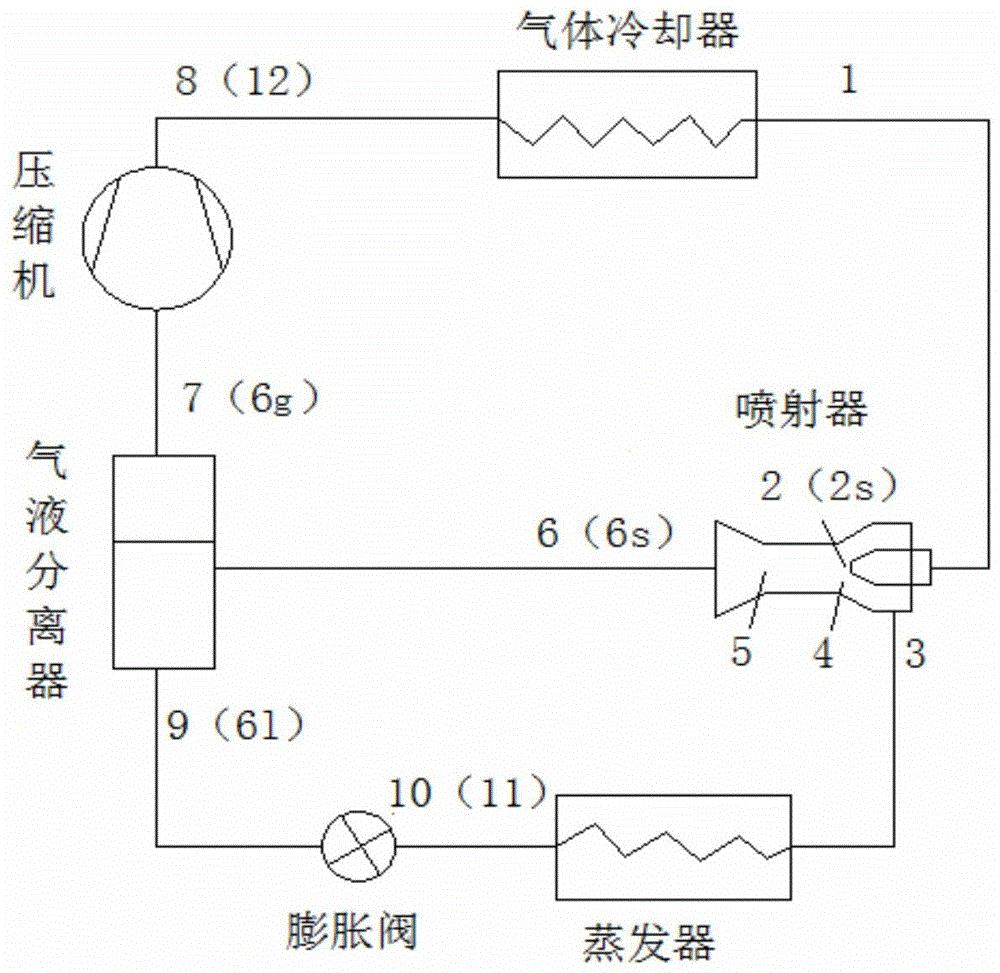

[0042] The method of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] like figure 1 As shown, the transcritical CO 2 The working process of the vapor compression / jet refrigeration system is:

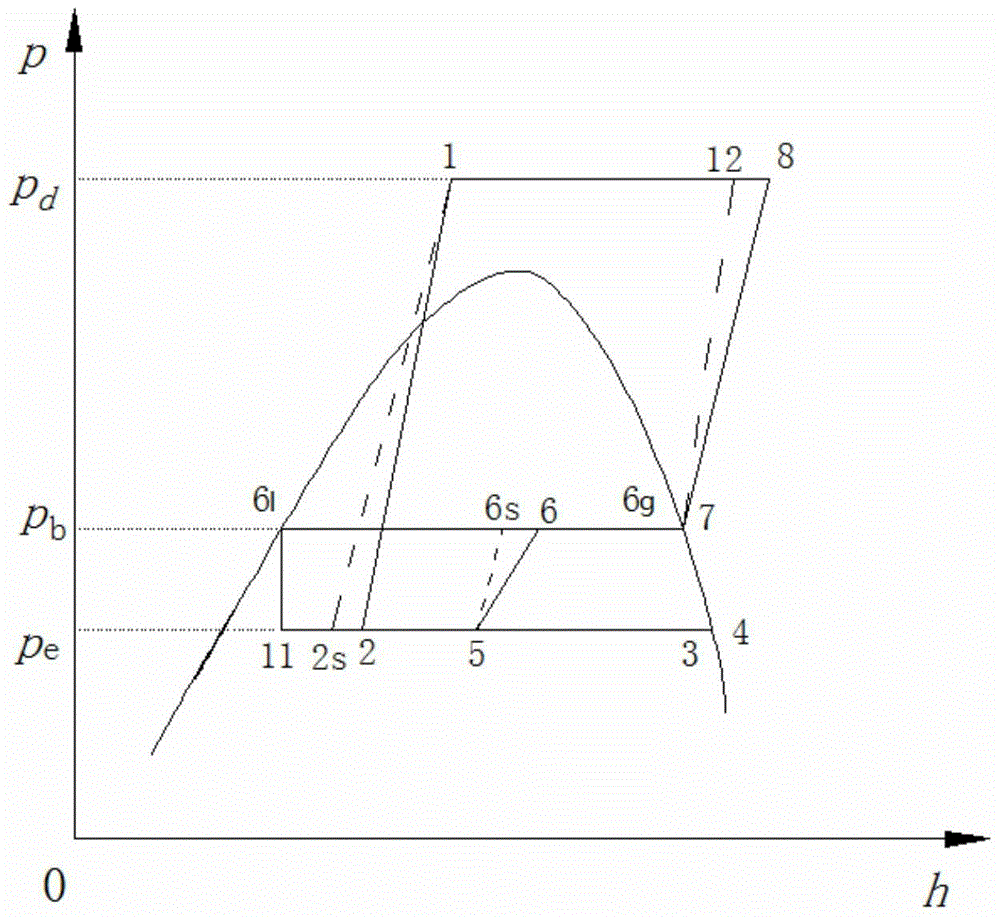

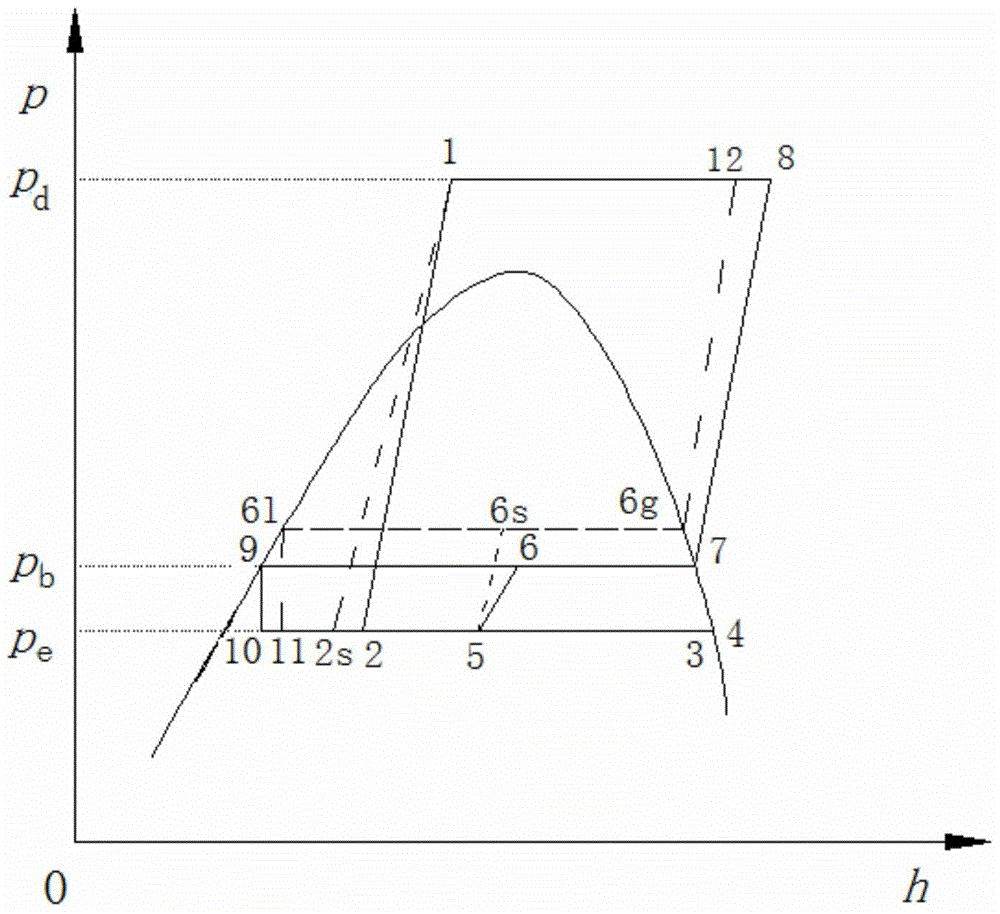

[0044] High pressure CO in thermodynamic state from the gas cooler 2 The gas enters the injector from the working fluid inlet 1, depressurizes and speeds up through the nozzle to the actual state outlet 2 (ideal cycle process isentropic expansion to the ideal state outlet 2s), when the pressure energy is converted into kinetic energy, the saturation from the evaporator outlet The steam is injected from the injection fluid inlet 3 to the mixing chamber inlet 4 of the suction chamber through the injection nozzle, and then isobarically mixed with the working fluid in the mixing chamber and enters the diffusion chamber inlet 5; then the mixed fluid is boosted to The actual state outlet 6 of the injector (ideal cycle process isen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com