Start-stop and load scheduling method of air separation pipe network device for uncertain demand

A technology for air separation plant and load scheduling, applied in the direction of design optimization/simulation, etc., can solve the problems of increased energy consumption, poor reliability, and increased difficulty of scheduling problems in adjusting the frequency of air separation, so as to speed up the solution, avoid low returns, and be feasible The effect of domain reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below with reference to the drawings.

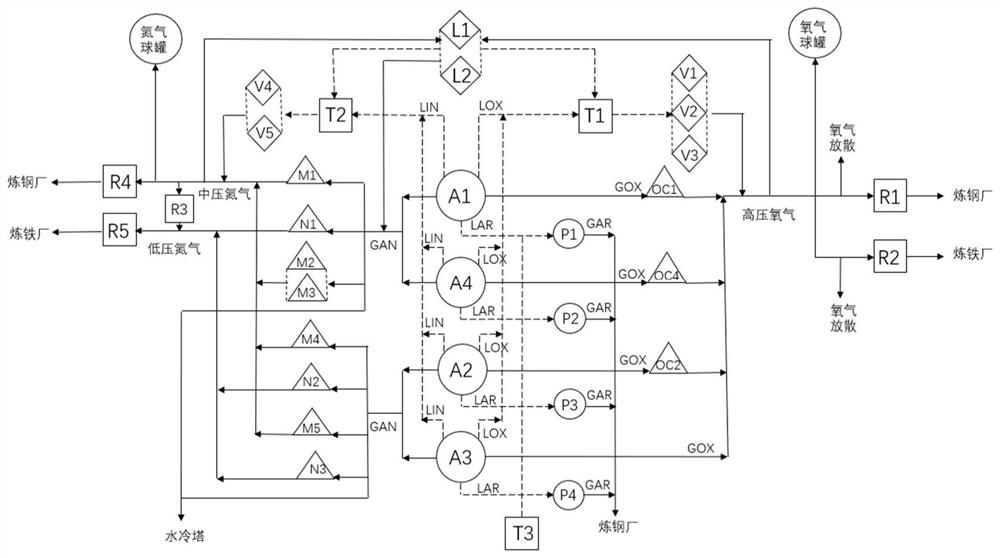

[0060] In this example, the margin network of Nanjing Iron and Steel Plant is an example, and the scheduling model of the pipe network is established. The specific process flow of the air separation network is like figure 1 Indicated. The entire space division system contains four large space division devices (A1 to A4), and the secondary air separation device is fixed load, No. 1, 3, and 4 of the air separation device. For the oxygen pipe network, the 3-speed divider can directly produce high pressure oxygen, and the oxygen generated by the other three devices must pass the oxygen press (OC1, OC2, OC4), and the pipe network is delivered to the user. If there is excess, it can disappear . For nitrogen gauge network, the nitrogen produced by the space division device passes through the compression of the medium pressure nitrogen press (M1-M5) and the low pressure nitrogen press (N1-N3), r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com