Offline burning system and method

A burning system and burner technology, applied in the direction of information storage, static memory, instruments, etc., can solve the problems of waste of resources, small scope of application, non-environmental protection, etc., achieve convenient disassembly, save economic cost and time cost, install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

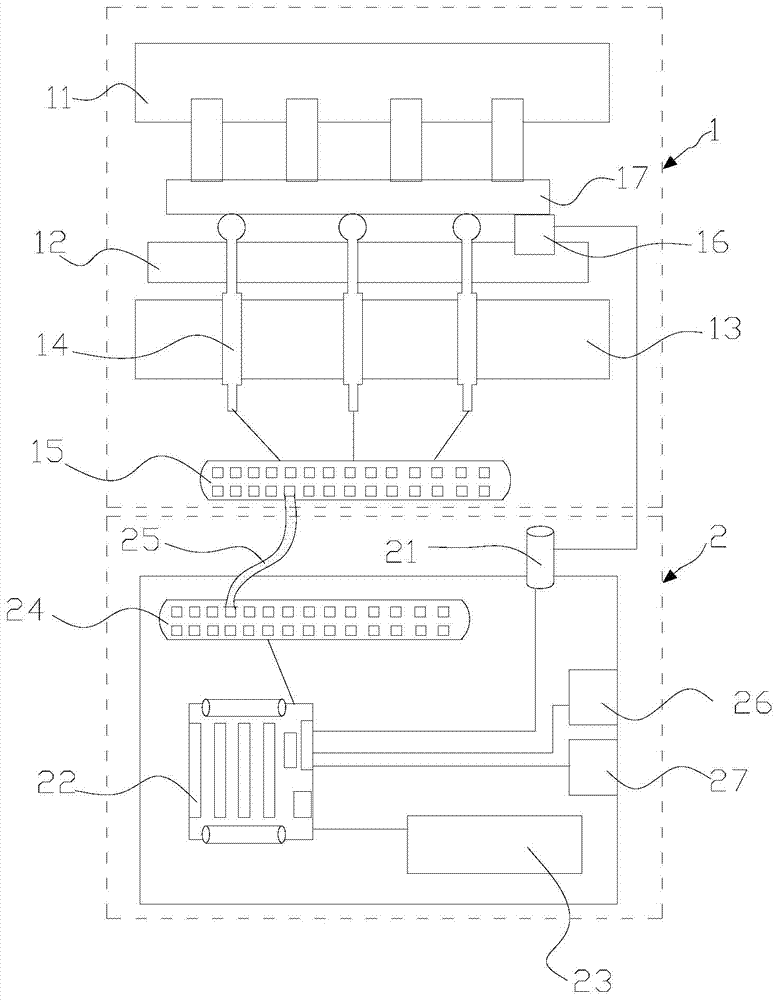

[0027] see figure 1 , The offline programming system of this embodiment includes a programming fixture 1 and a programming fixture box 2, and the programming fixture 1 is installed in the programming fixture box 2 for use together. The programming jig 1 includes an upper cover 11, an IC installation area 12 to be programmed, a needle bed 13, a probe 14, a first interface 15, and a micro switch 16. The needle bed 13 of this embodiment is arranged on the IC to be programmed. Below the area 12, the probe 14 is fixed on the needle bed 13, and one end of the probe 14 is connected to the first interface 15, and the other end is located above the IC mounting area 12 to be burned, for contacting the IC 17 to be burned The micro switch 16 is located on the IC installation area 12 to be burned; the burning fixture box 2 includes a sensor 21, a burner 22, a power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com