Power guided chain with rollers

A chain and power technology, which is applied in the field of power guide chains, can solve the problems of uneconomical production and manufacturing costs of bottom parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

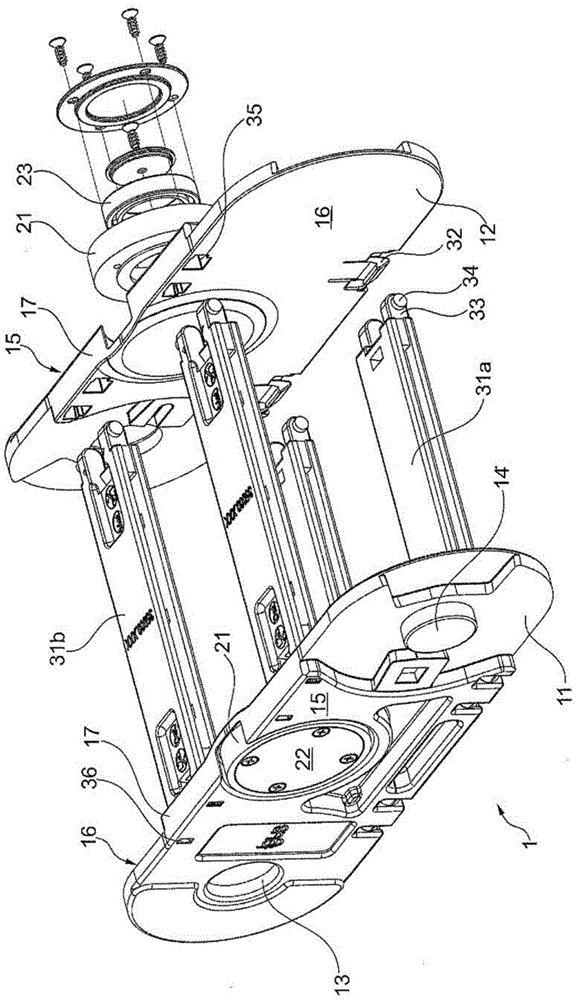

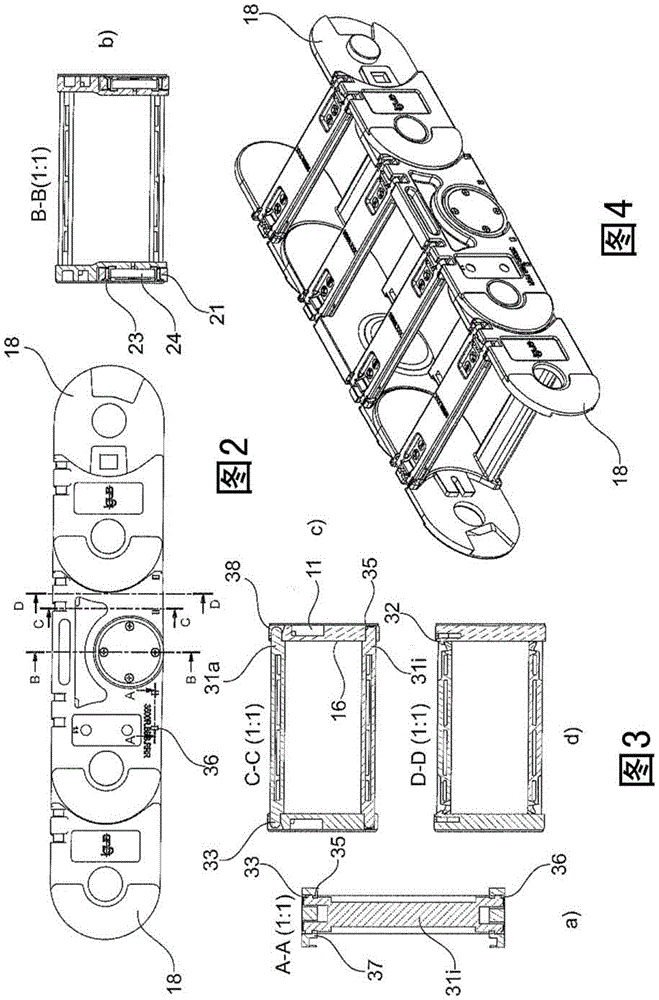

[0024] Figure 1 is a perspective view of a chain link 1 with features of the present invention. The chain link comprises two side plates 11, 12 which are mirror images of each other and have respectively a pivot sleeve 13 and a pivot journal 14 which are used during assembly. It is pivotally connected to the adjacent chain link. On the end with the pivoting sleeve 13 , the side plate 11 forms the outer surface 15 of the chain link 1 , while the inner surface 16 of the side plate 11 is exposed on the end with the pivot journal 14 .

[0025] The rollers 21 are recessed into the side plates 11 , 12 . The rollers are supported by ball bearings 23 on pivot journals 24 (not shown) and are protected by screwed covers 22 . When the chain is stretched out, the narrow faces 17 of the side plates 11, 12 form a continuous active surface on which the rollers 21 can roll.

[0026] Located between the side plates are beams 31, in this case two inner beams 31i close to the active surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com