Guide roller, film conveyance apparatus, and sheet forming machine

A technology for conveying devices and guide rollers, which is applied to the device for coating liquid on the surface, winding strips, sending objects, etc., and can solve problems such as uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

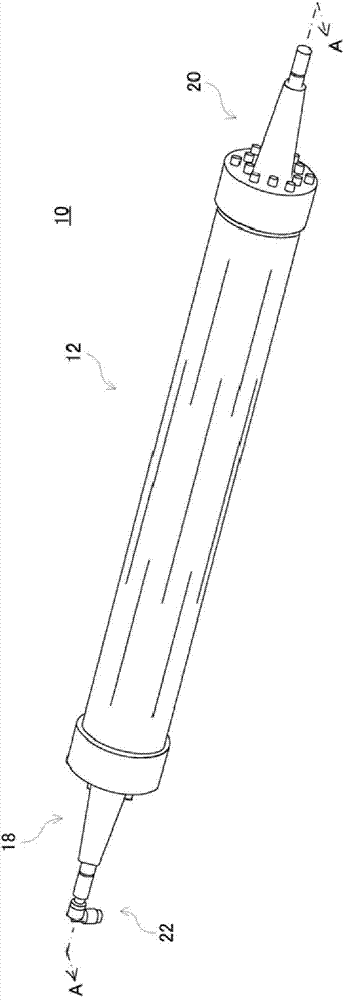

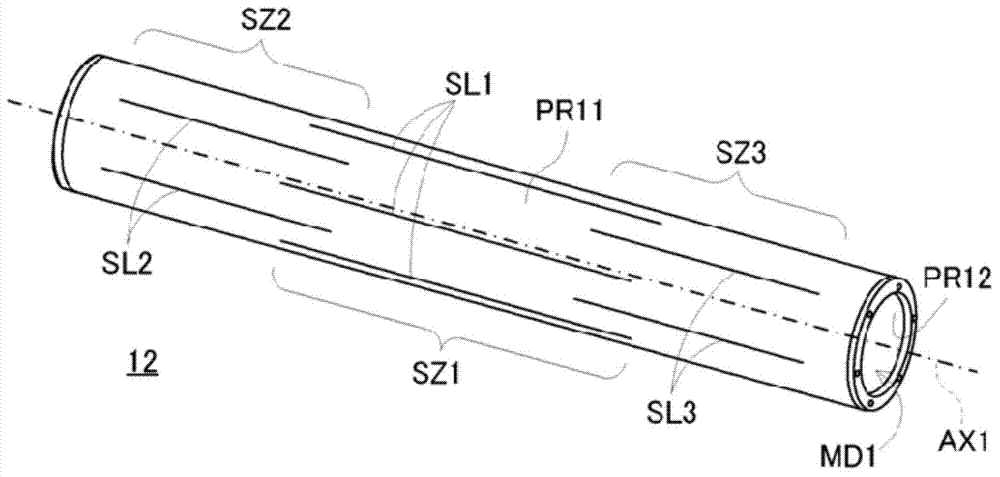

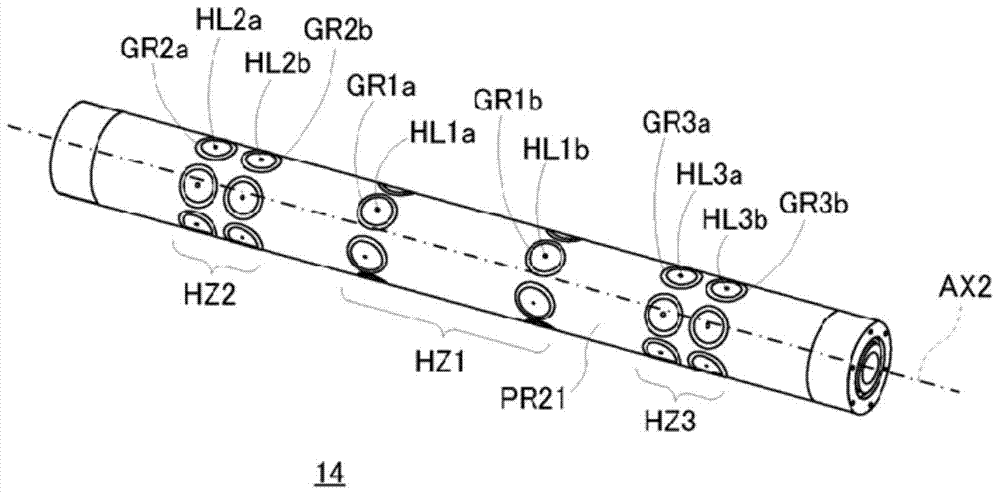

[0029] figure 1 The appearance of the guide roller 10 of this embodiment is shown. The guide roller 10 is composed of an outer roller 12 and an inner roller 14 respectively shown in FIG. 2(A) and FIG. 2(B). An O-ring 16 shown in FIG. 3(A) is attached to the inner roller 14 . The journals 18 and 20 and the rotary joint 22 respectively shown in FIGS. 4(A) to 4(C) are attached to the guide roller 10 . The outer roller 12 and the inner roller 14 are respectively fixed by journals 18 and 20 and rotate together in the circumferential direction.

[0030] Referring to FIG. 2(A), the outer roller 12 has a cylindrical shape along the axis AX1. The outer roller 12 is made of, for example, stainless steel, aluminum, iron or resin. The overall length of the outer roll 12 is several hundred mm, and the thickness of the outer roll 12 is in the range of several mm to several tens of mm. The outer diameter of the outer roll 12 is defined by the outer peripheral surface PR11 of the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com