Rising pipe arranged between steel ladle and vacuum chamber

A vacuum chamber and ladle technology, applied in the field of riser, can solve the problems of rotating jet energy attenuation, prolonging the smelting time, etc., and achieve the effect of large expansion angle, strong entrainment and mixing ability, and reduced splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

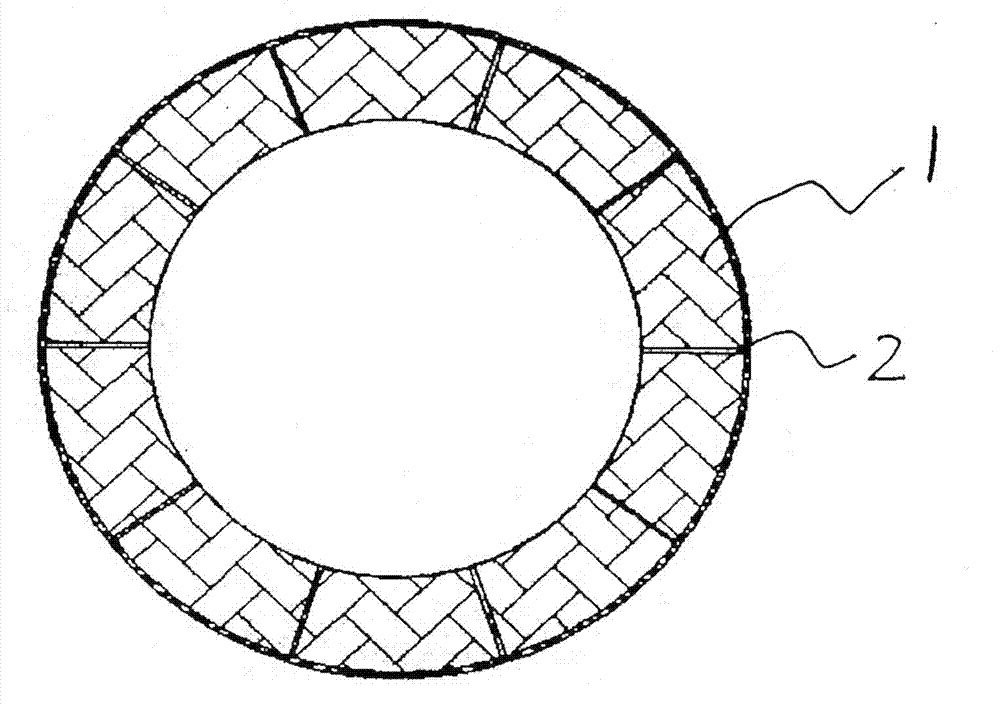

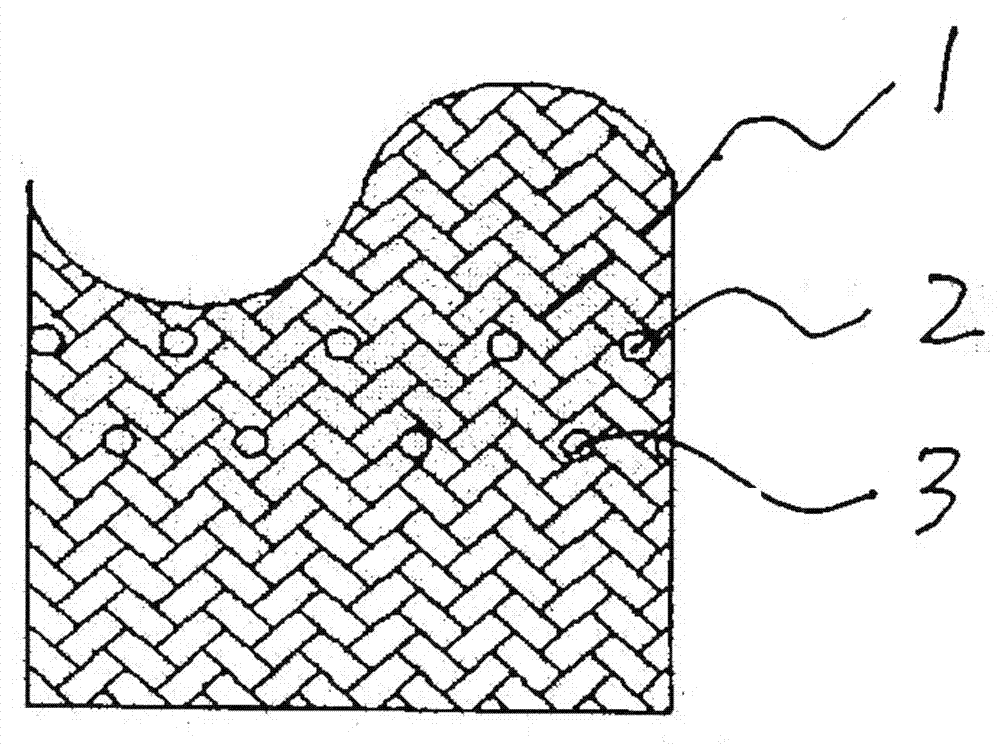

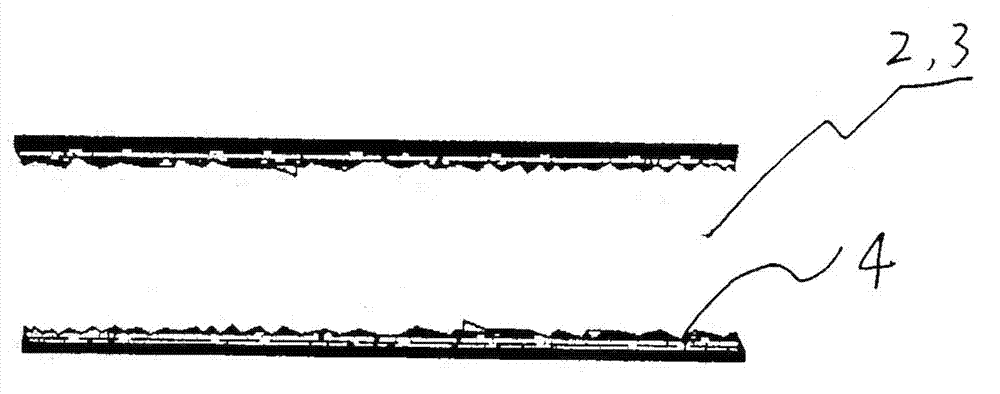

[0012] Such as Figure 1 to Figure 3 , these three drawings show the appearance structure schematic diagram of the rising tube arranged between the ladle and the vacuum chamber proposed by the present invention. The rising pipe is composed of a cylindrical hollow part 1, and the radial direction of the cylindrical hollow part 1 is provided with a first row of through holes 2 and a second row of through holes 3. The first row of through holes 2 proposed in this embodiment and the second row of through holes 3 are respectively provided with 10 through holes equidistantly spaced,

[0013] And the first row of through holes 2 and the second row of through holes 3 are misaligned up and down, that is, they are not on the same straight line in the axial direction, because the number of through holes can be determined according to the diameter of the cylindrical hollow part 1 , usually 8-13 through holes can be set; in addition, the inner surface of each through hole in the first row...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com