Equipment cabinet convenient for circuit arrangement

It is a circuit and convenient technology, which is applied in the direction of casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, cooling/ventilation/heating transformation, etc. It can solve the problems of messy internal lines and inconvenient arrangement, and achieve The height and space size can be adjusted, the operation is convenient, and the finishing effect is effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

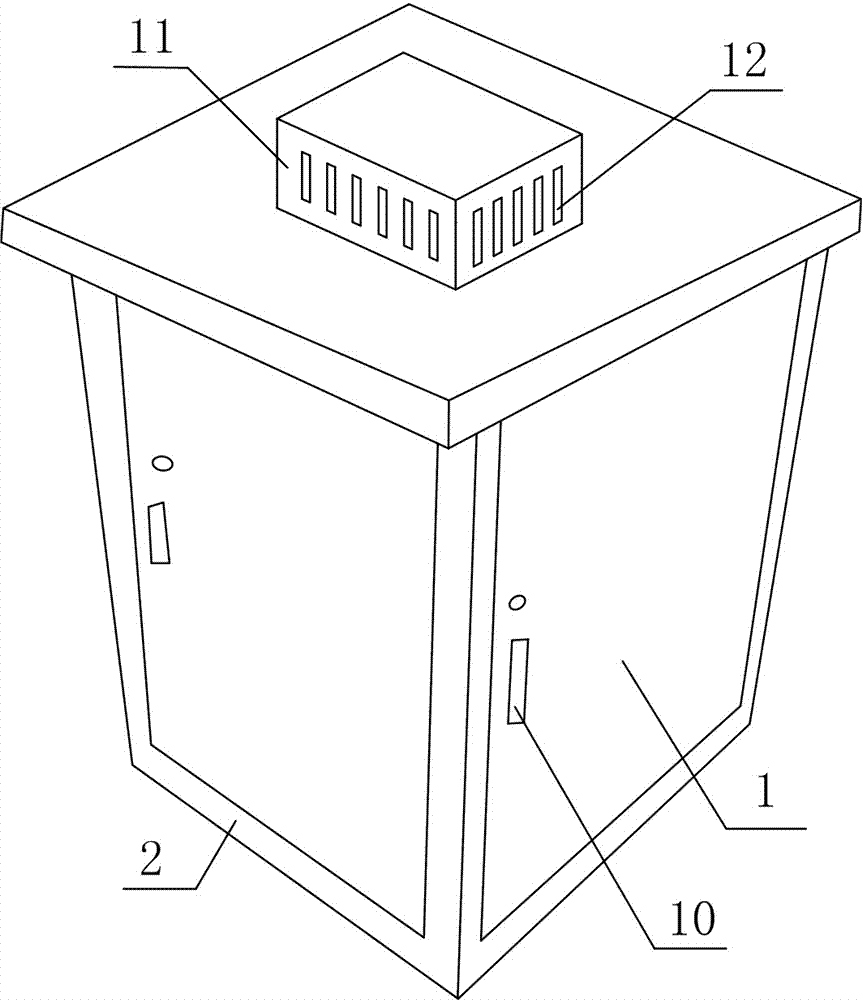

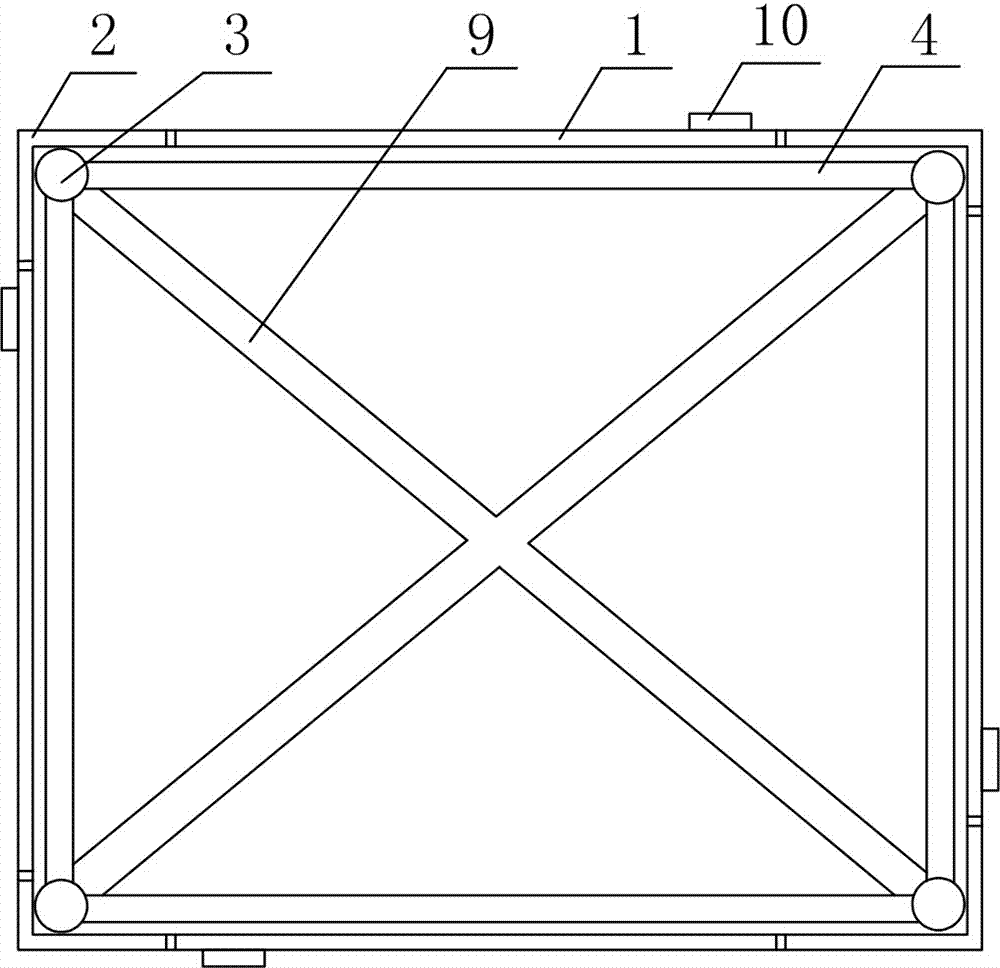

[0031] Convenient line management cabinets, such as Figure 1~4 As shown, it includes a casing 2 provided with cabinet doors 1 on four sides, a frame body arranged inside the casing 2 for supporting the casing 2, and a partition shelf set on the frame body, and placing A shelf on the shelf shelf.

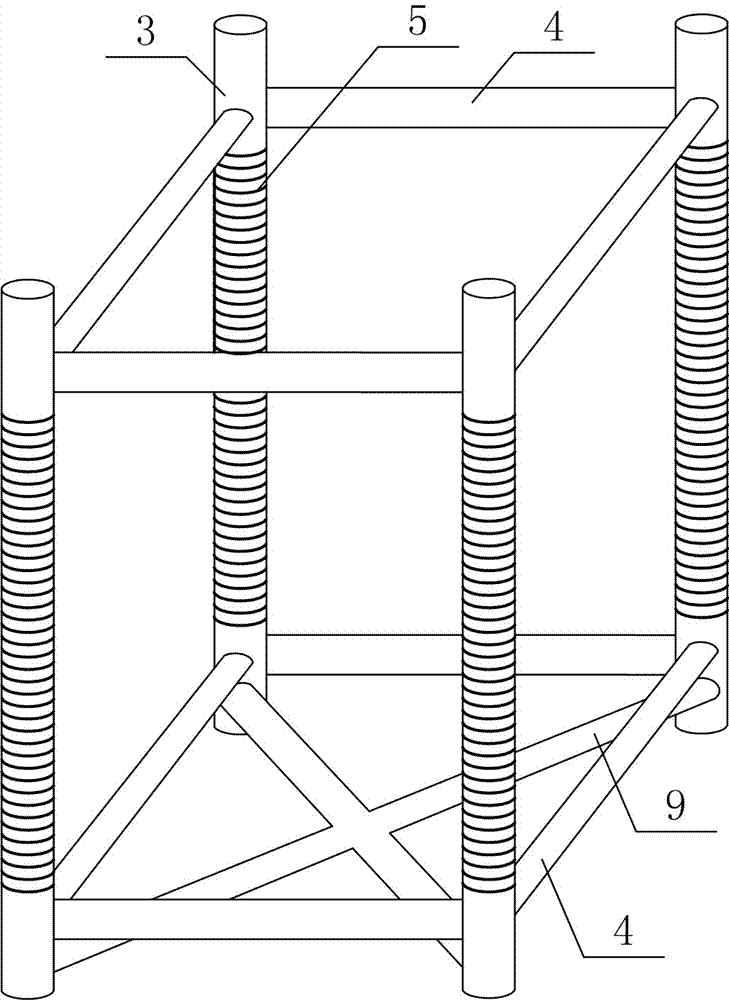

[0032] Wherein, the frame body consists of four columns 3 arranged in parallel and in a rectangular arrangement, connecting rods 4 arranged at the bottom and top of the columns 3 and connecting two adjacent columns 3 , and annular grooves arranged on the columns 3 5 composition.

[0033] The partition shelf is composed of a fastening piece 6 that is fastened on the column 3, a protruding piece 7 that is arranged on the inner surface of the fastening piece 6 and matches the annular groove 5, and a protrusion that is arranged on the fastening end of the fastening piece 6. Bolt fixing holes 8, as well as bolts and nuts that fix the fastener on the column 3 through the bolt fixing hol...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the structure of the housing 2 and the frame, such as figure 1 and image 3 As shown, the specific setting method is as follows:

[0038] A cross connector 9 is provided at the bottom or / and top of the column 3 . In this embodiment, the cross connector 9 is only arranged at the bottom of the column 3 .

[0039] In order to facilitate opening and closing of the cabinet door 1 , a handle 10 is provided on the cabinet door 1 .

[0040] At the same time, in order to achieve a better heat dissipation effect, the top of the housing 2 is provided with a heat dissipation device, and the bottom end of the heat dissipation device communicates with the box body 11 inside the housing 2, and the heat dissipation air holes arranged on the side wall of the box body 11 12 compositions. An exhaust fan is also arranged inside the box body 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com