High and low temperature damp heat test chamber

A damp heat test, high and low temperature technology, applied to laboratory appliances, heating or cooling equipment, shells or chambers, etc., can solve the problems of procurement funds, space, energy waste, difficult to achieve thermal load capacity, etc., to achieve control equipment Cost and equipment volume, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

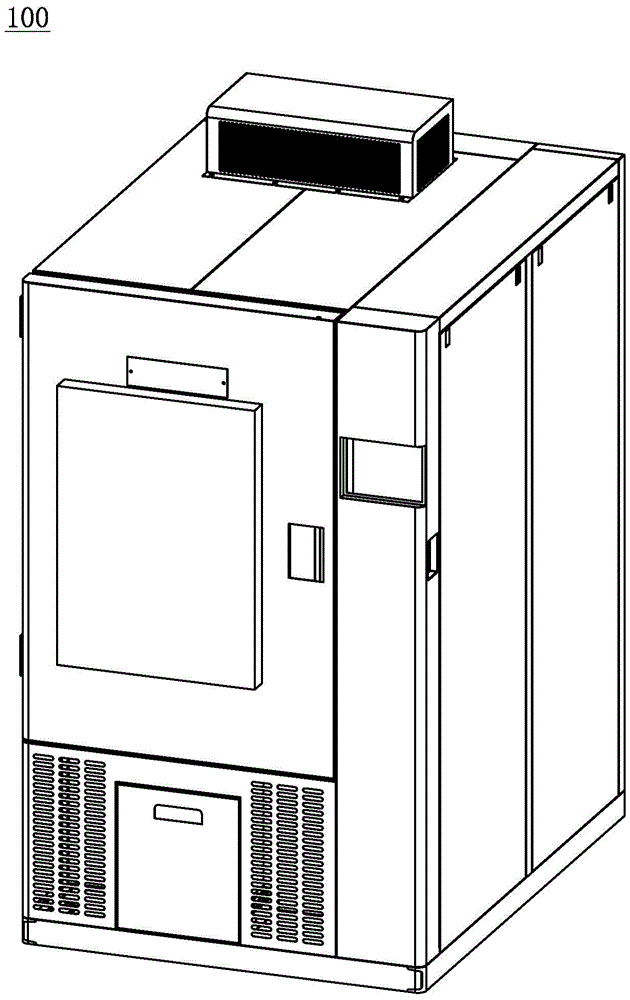

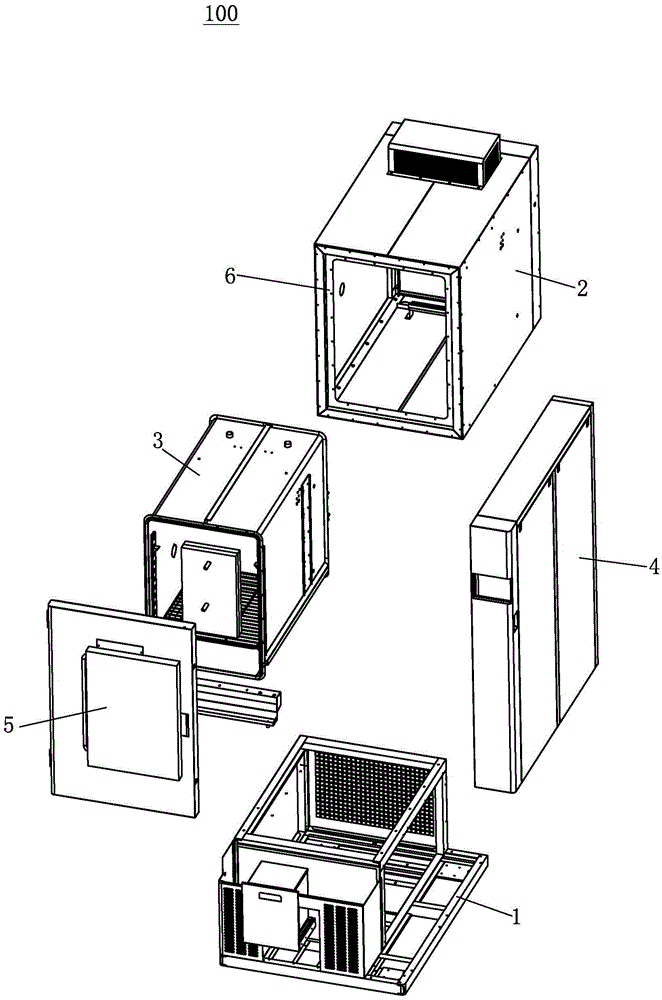

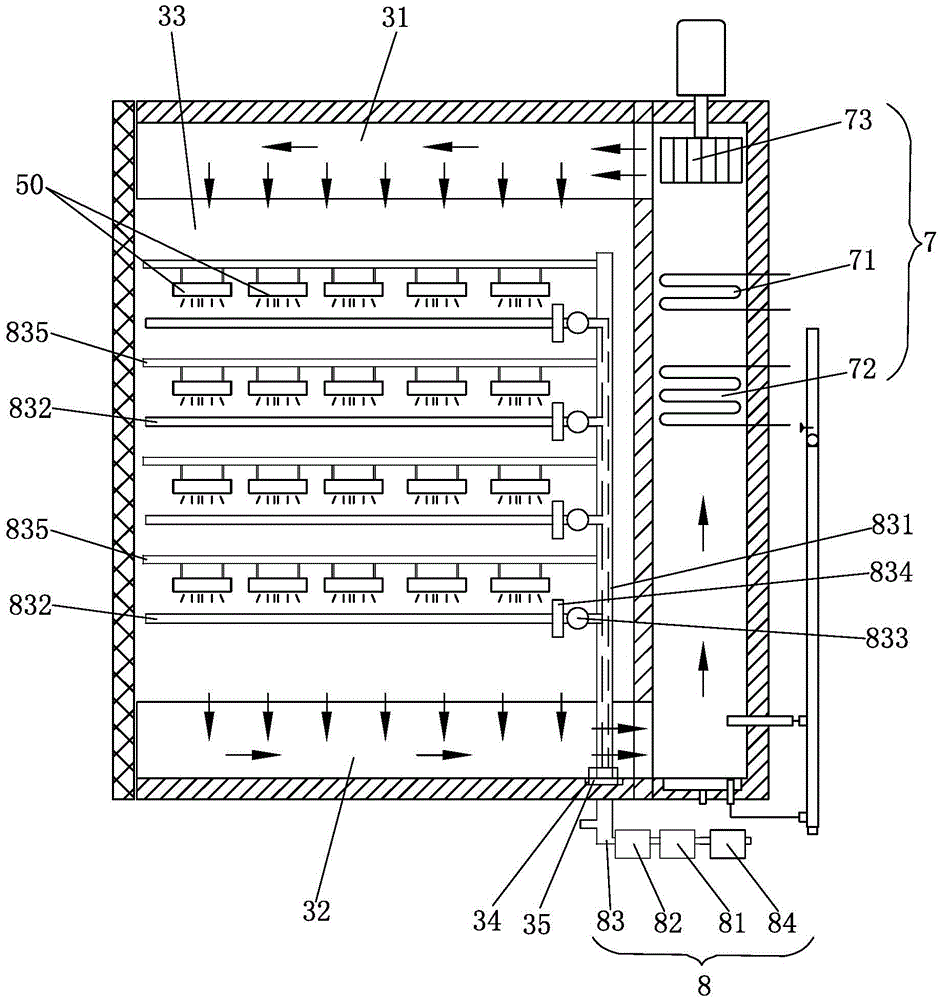

[0023] Now refer to the attached figure 1 To describe embodiments of the present invention, like reference numerals in the drawings represent similar elements. As mentioned above, such as Figure 1-5 As shown, the high and low temperature damp heat test chamber 100 disclosed in the embodiment of the present invention includes: a bracket 1, an outer box body 2, an inner box body 3, a side box body 4, a box door 5 and a processing device 7. The inner box 3 is nested inside the outer box 2, the processing device 7 is arranged in the side box 4, the side box 4 is attached to one side of the outer box 2, and the outer box An insulating layer 6 is provided between the box body 2 and the inner box body 3, and a channel is provided between the side box body 4, the outer box body 2 and the inner box body 3, and the channel is as Figure 4 As shown, it is arranged on the opposite side walls of the inner box body 3 and the side box body 4, and holes are opened at the upper and lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com