Silicon steel sheet supporting sheet device for high-speed notching machine

A high-speed punching and silicon steel sheet technology, applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as difficulty in taking sheets, damage to centering holes, etc., to facilitate secondary positioning and ensure indexing Accuracy, easy to take the effect of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

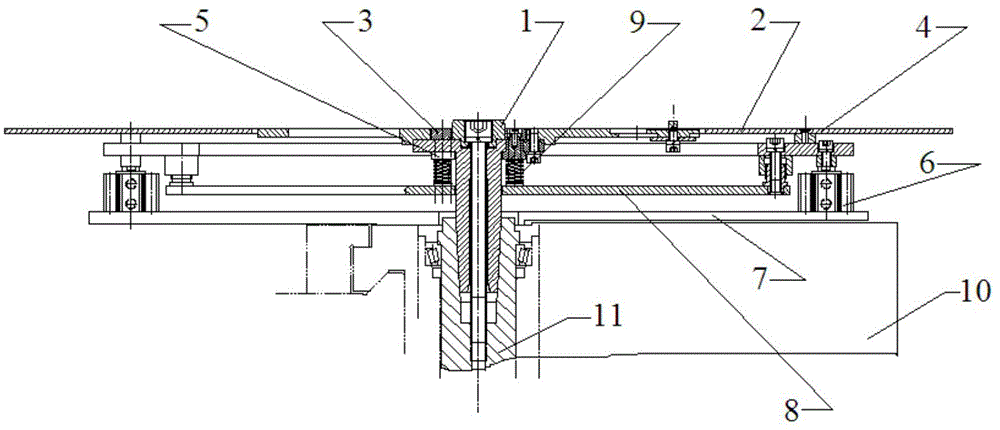

[0010] see figure 1 , a device for supporting silicon steel sheets on a high-speed notching machine, comprising an organic machine indexing seat 10, a cylinder connecting plate 7, a cylinder 6, upper and lower supporting plate connecting plates 4, 8, a supporting plate 2, a supporting plate The ring 3 and the centering head 1, the cylinder connecting plate 7 are fixed on the indexing seat 10 of the machine tool, the cylinder 6 is fixed on the cylinder connecting plate 7, the upper and lower support plate connecting plates 4 and 8 are fixedly connected together, the piston rod of the cylinder 6 The end of the upper support plate 4 is fixedly connected to the bottom of the upper support plate 4, and the support plate 2 is fixedly connected with the upper support plate 4; The main shaft 11 rotates at a high speed, the support ring 3 is fixed on the centering head 1, the support ring 3 is fixedly connected with a positioning pin 5, the positioning pin 5 is covered with a spring 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com