A precision indexing device and method for large shaft parts

A technology of shaft parts and indexing devices, which is applied in the field of processing and manufacturing, can solve the problems of positioning and alignment errors affecting indexing accuracy, increasing indexing torque, and affecting indexing accuracy, so as to achieve good indexing accuracy and eliminate indexing Influence of accuracy, effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

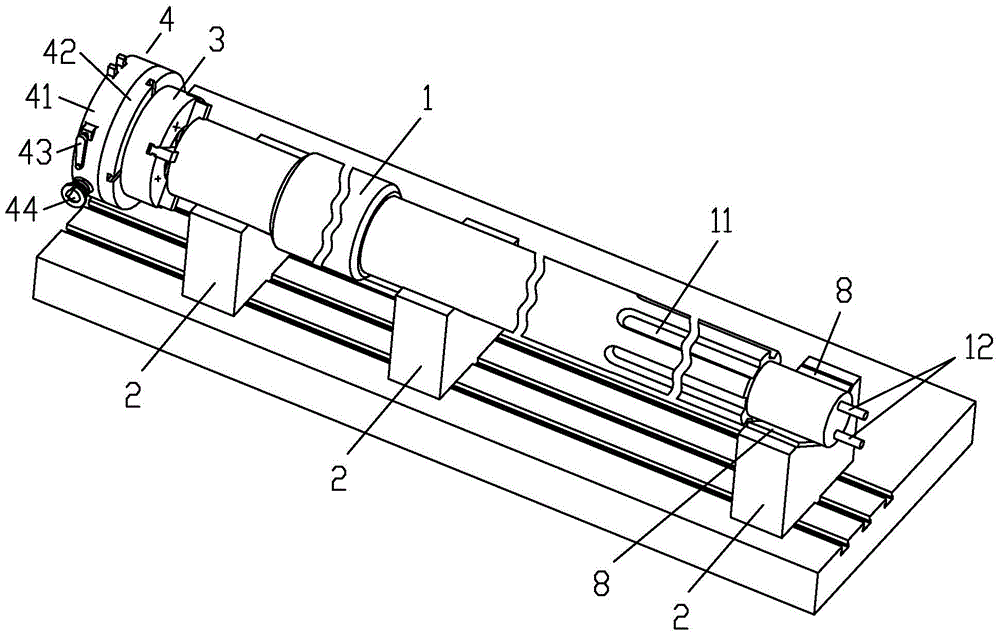

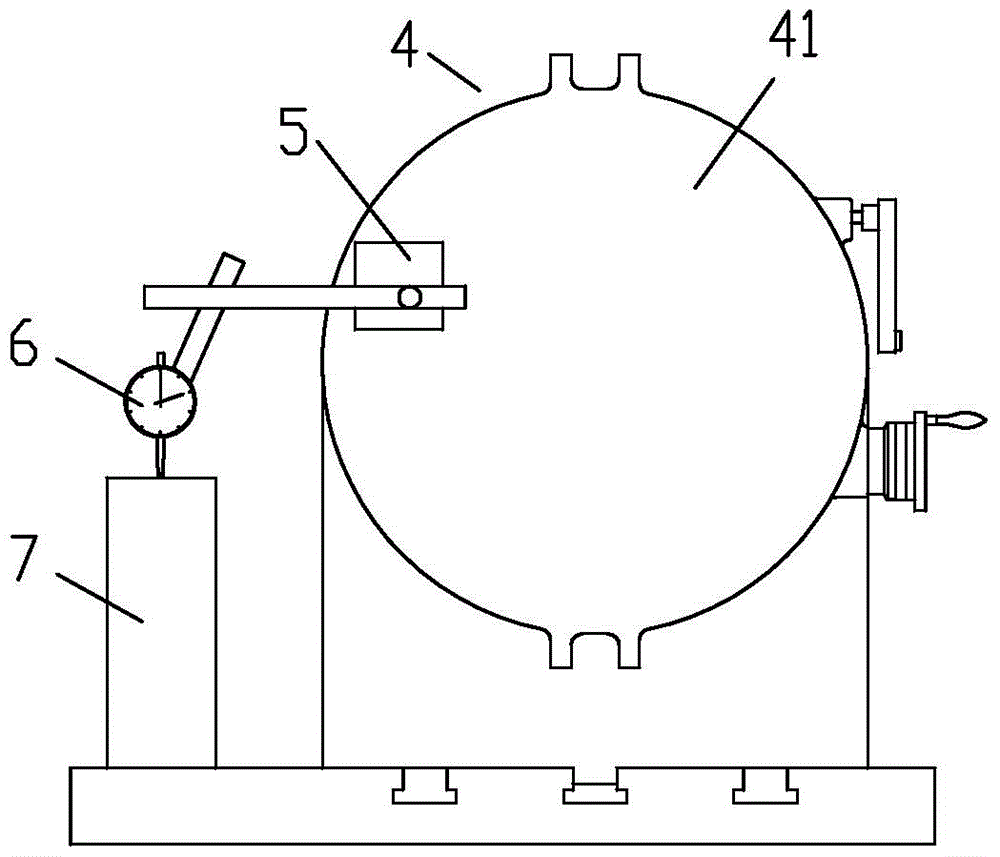

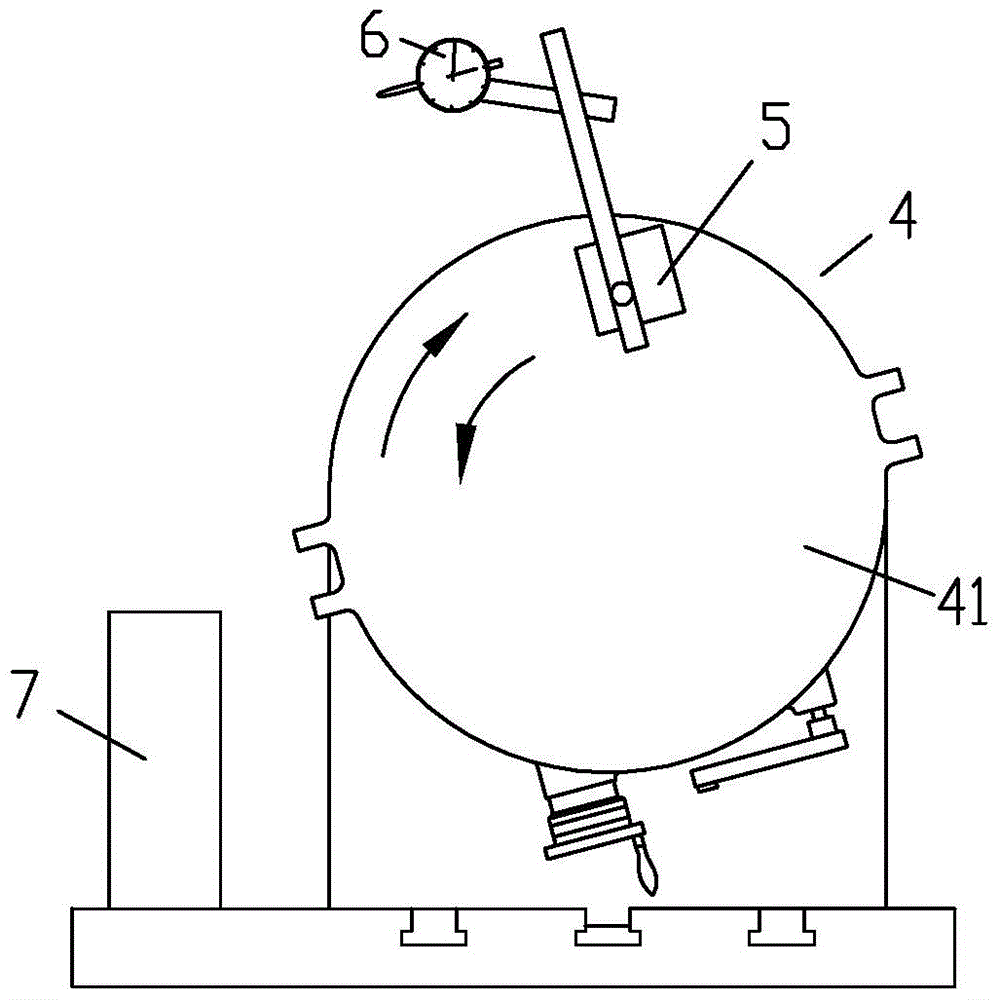

[0029] Example 1 see figure 1 , figure 2 , image 3 , a precision indexing device for large shaft parts, including three equal-height V-shaped irons 2 for supporting shaft parts 1 and fixed on a working platform, and a general-purpose indexing plate 4 for indexing; Among them, two equal-height V-shaped irons 2 are respectively supported on two equal-diameter outer cylindrical sections of the shaft part 1, and the other equal-height V-shaped iron 2 is supported on the other end of the shaft part 1 whose diameter is smaller than the aforementioned two cylindrical sections. The tail section is provided with equal-thickness pads 8 on the V-shaped two support surfaces of the equal-height V-shaped iron 2, and the thickness of the equal-thickness pads 8 is equal to the radius difference between two unequal-diameter cylindrical sections; wherein, The indexing plate 4 is clamped and fixed on the outer circle of one end of the shaft part 1 by the four-jaw chuck 3, and by adjustin...

Embodiment 2

[0031] Example 2 , see figure 1 , figure 2 , image 3 , a precision indexing method for large shaft parts, comprising the following steps.

[0032] The first step includes the sub-steps of parts installation and alignment and index plate installation and alignment.

[0033]The parts installation and alignment are divided into steps, including first installing the large-scale shaft part 1 to be processed by milling on the working platform through three equal-height V-shaped irons 2, and the three equal-height V-shaped irons 2 Cooperate with the positioning groove of the milling machine table through the positioning key provided on it for positioning, and fix the V-shaped iron 2 with the milling machine table; wherein, two equal-height V-shaped irons 2 are supported on the two shaft parts 1 respectively. The outer cylindrical section of equal diameter, another equal height V-shaped iron 2 is supported on the other end tail section of the shaft part 1 whose diameter is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com