Low-loss and high-precision radial electromagnetic suspension bearing

An electromagnetic levitation, high-precision technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. problems such as hidden dangers, to achieve the effect of small heat generation, scientific and reasonable structural design, and good assembly links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

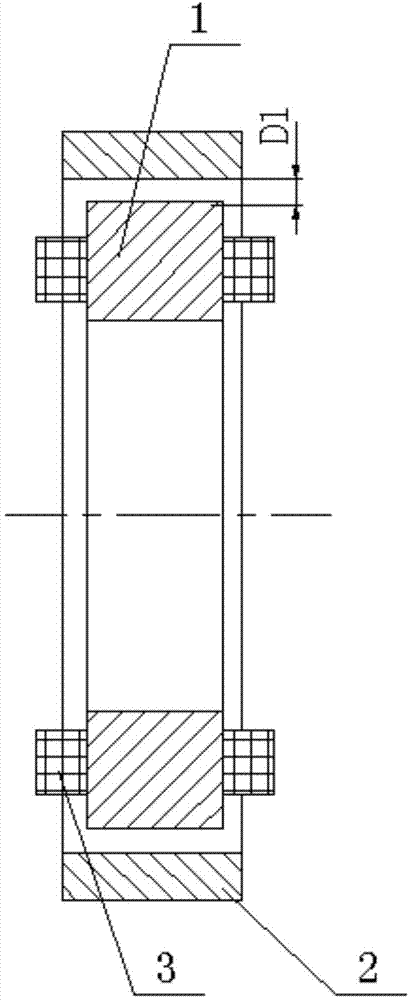

[0020] A low-loss, high-precision radial electromagnetic suspension bearing, including a rotor core 2, a stator core 1, and an excitation coil 3, the rotor core is fixedly connected to the instrument pivot, and the stator core is fixedly connected to the instrument bracket Together, the rotor core is located radially inside the stator core.

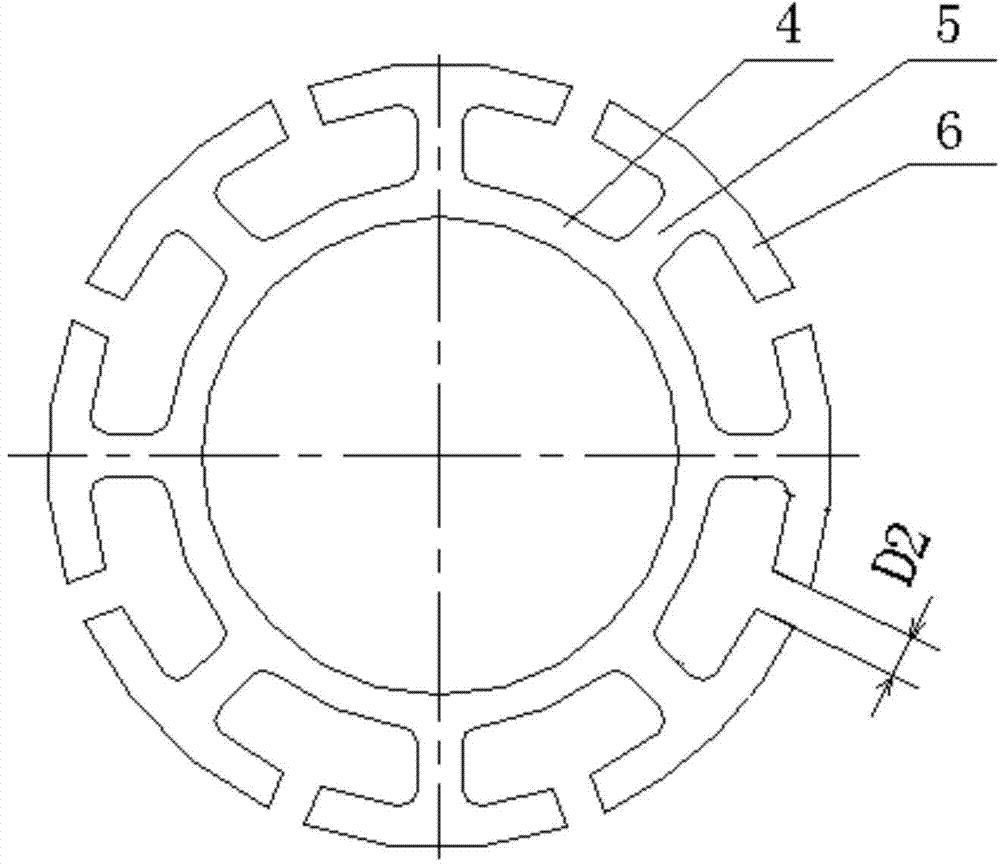

[0021] The innovation of the radial electromagnetic suspension bearing lies in that the stator core is composed of 8 to 20 magnetic poles 5 made of a magnetically permeable ring 4 and its outer periphery, eight magnetic poles in this embodiment. Two adjacent magnetic poles and the coils wound on them form a group of working magnetic poles, the magnetic poles are pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com